Rotor for laboratory centrifuges

A laboratory centrifuge and laboratory technology, applied in the field of centrifuge rotors, can solve the problems of rotor shell damage, resonance, imbalance, etc., and achieve the effect of improving the stability of the bearing structure, eliminating axial displacement, and reducing imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following drawings, the same parts will be marked with the same.

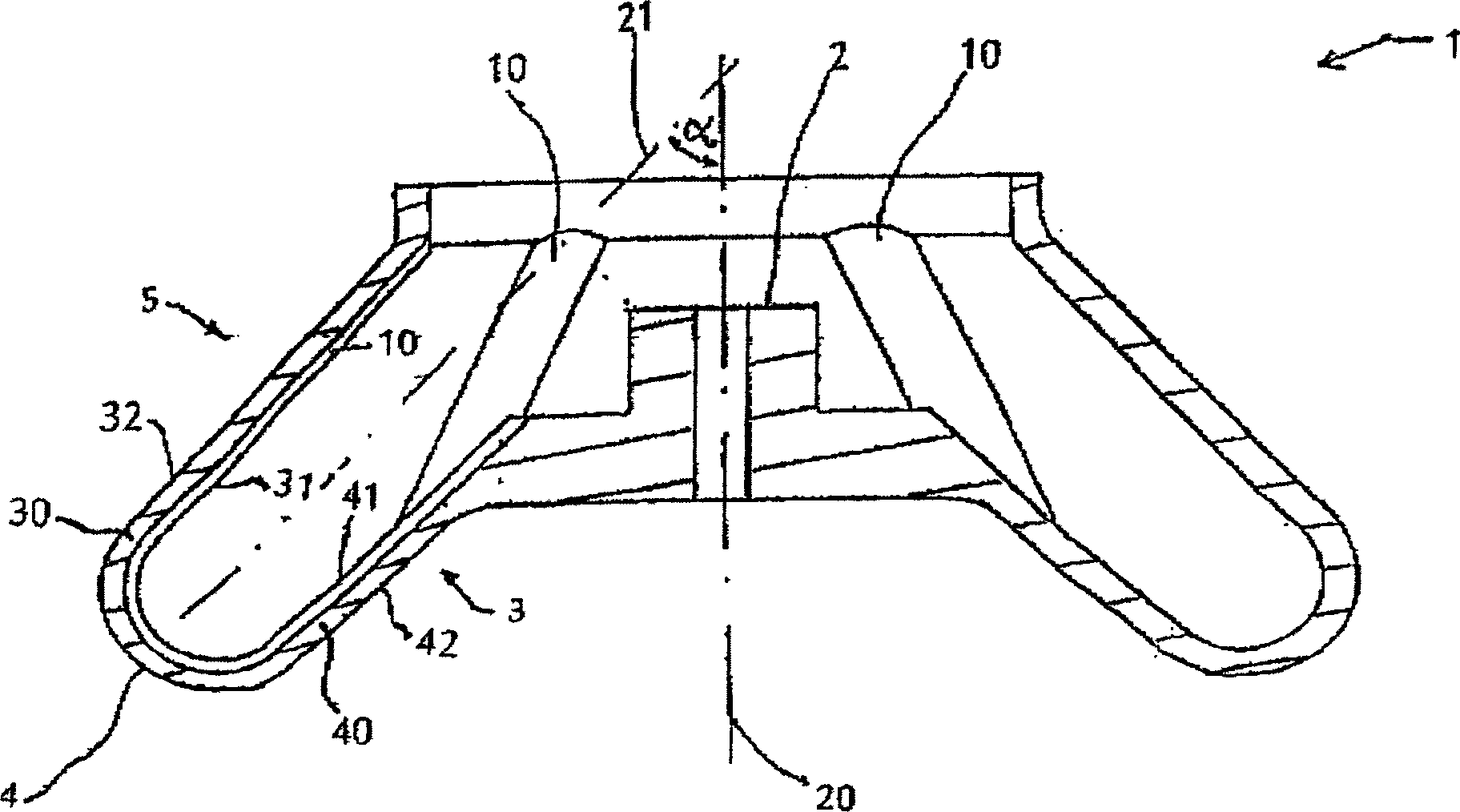

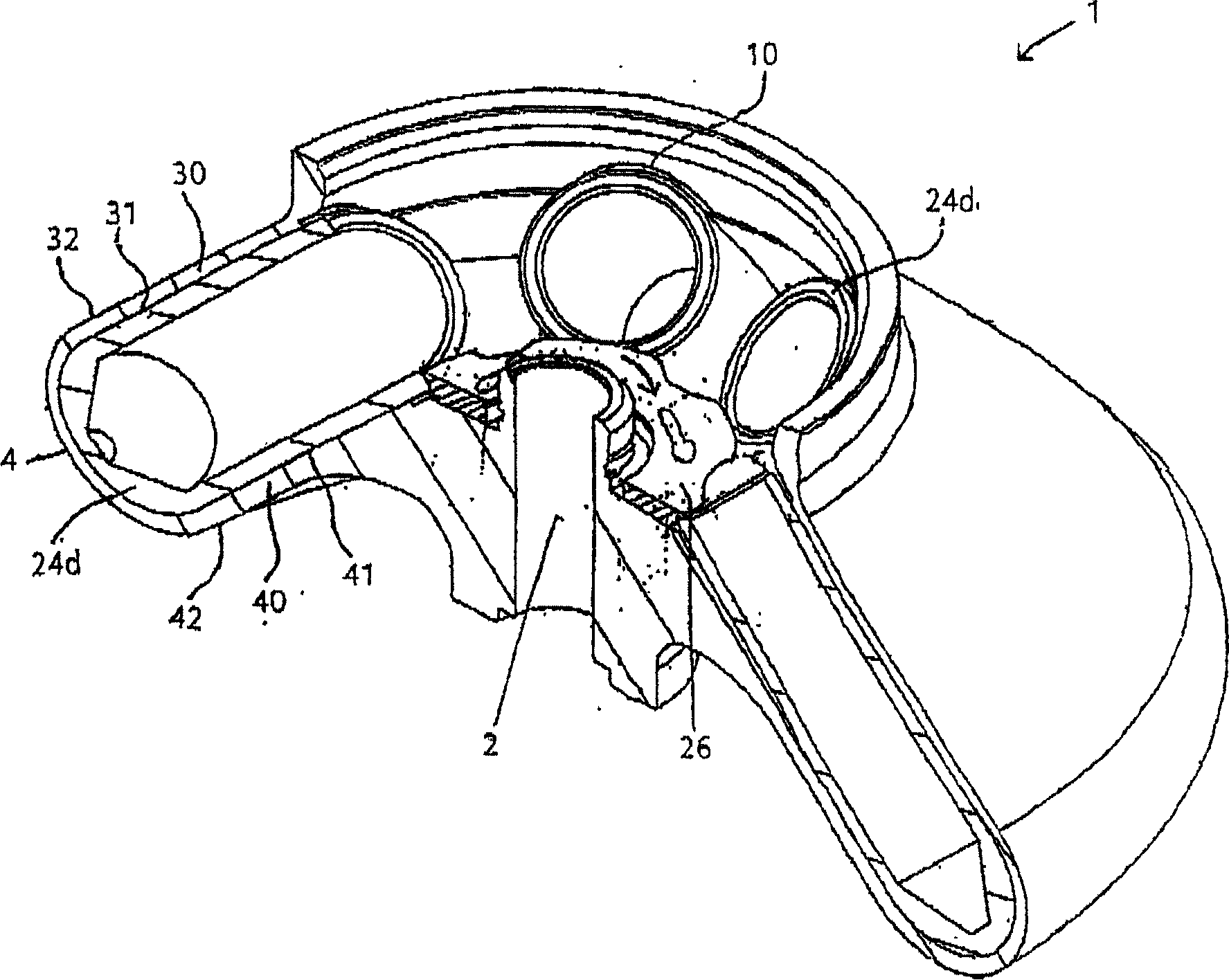

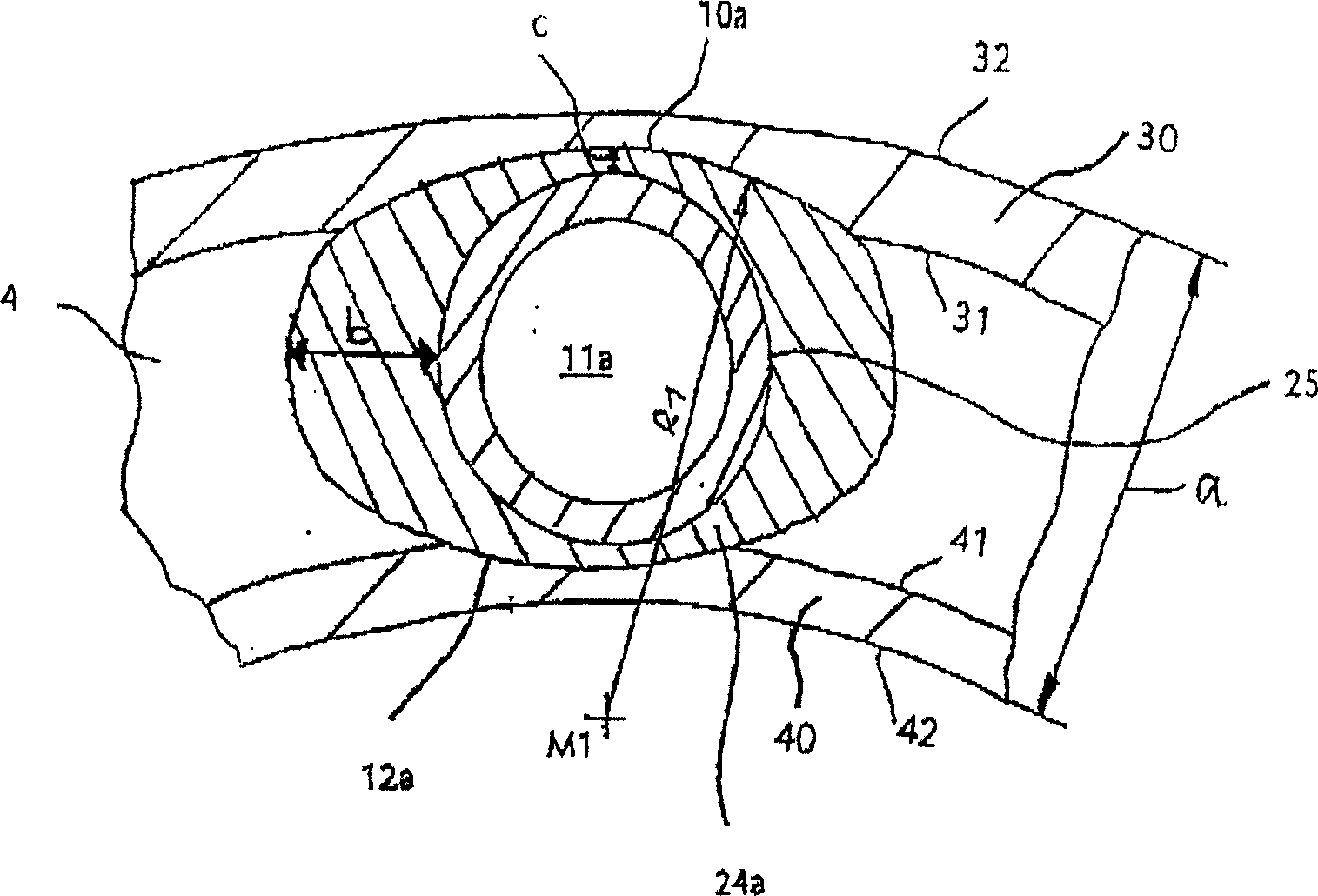

[0037] figure 1 It is a longitudinal sectional view of the entire rotor shell 1, the rotor hub 2 is assembled in the center of the truncated cone 3 that decreases from bottom to top, and the middle part of the rotor shell is composed of the truncated cone and the rotor hub 2. The truncated cone 3 is part of the annular groove 4 and a substantial part of the inner wall 40 is formed by the truncated cone 3 . In addition, in the annular groove, the concave truncated cone 5 that decreases continuously from bottom to top is located on the side opposite to the truncated cone 3 , that is, on the outer wall 30 of the rotor housing 1 formed by the concave truncated cone 5 . The annular groove 4 includes the inner edge of the inner wall 41 and the inner edge of the outer wall 31 , and the outer edge of the inner wall 42 and the outer edge of the outer wall 32 . The peripheral area consists of an annular g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com