Physical foaming method for producing electric cable

A physical foaming and cable technology, applied in the direction of insulating conductors/cables, can solve the problems of increasing workload and difficulty, increasing product cost, affecting product performance, etc., to improve product quality, increase production speed, The effect of product rejection rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

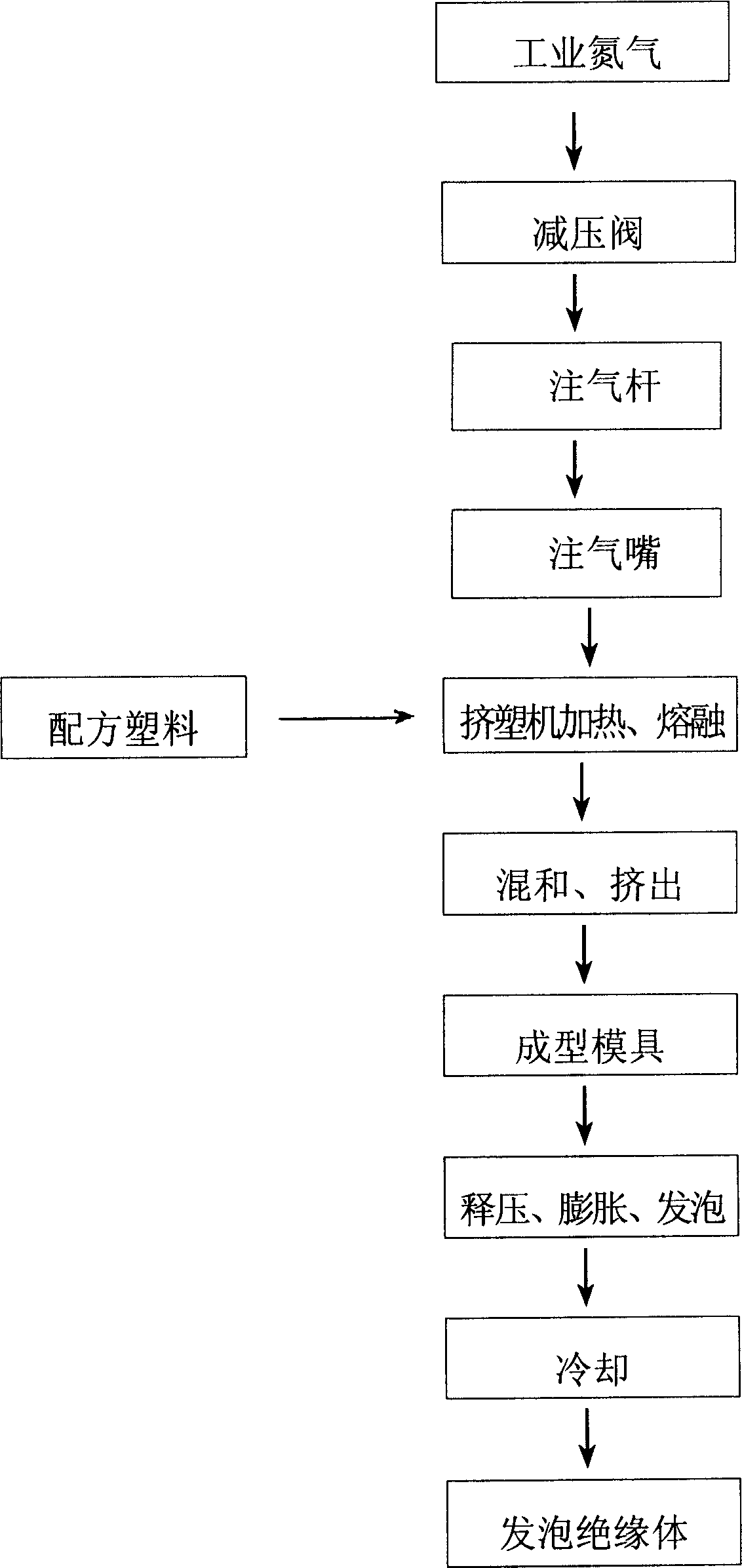

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Utilize the method of the present invention to produce SYWY-75-7 product.

[0018] Raw material preparation: electrical round copper wire Ф0.12, 99.99% industrial nitrogen, 1I2A-1LDPE, HD6070EAHDPE, nucleating agent. The raw materials required by the present invention are electrical round copper wire Ф0.12, 99.99% industrial nitrogen, 1I2A-1LDPE, HD6070EAHDPE, nucleating agent, special material for physical foaming, etc. can be purchased in the domestic market. PE plastic pellets are purchased by companies such as Beijing Yanshan Petrochemical Company or Xinjiang Dushanzi Petrochemical Company. Copper wires are purchased from Chengdu Shuangliu Copper Material Factory or Deyang Jingchang Copper Wire Factory.

[0019] Process indicators: product specification SYWV-75-5, air injection aperture 0.8mm, air injection pressure 3Mpa, inner skin mold core aperture Ф1.05, inner skin mold sleeve aperture Ф1.10, foam core aperture Ф1.30, foaming mold Hole diameter Ф...

Embodiment 2

[0023] Embodiment 2: Utilize the method of the present invention to produce SYWLY-75-12 product.

[0024] Raw material preparation: electrical round copper wire Ф2.77, 99.99% industrial nitrogen, 1I2A-1LDPE, HD6070EAHDPE, nucleating agent. Electrical round copper wire Ф2.2, 99.99% industrial nitrogen, 1I2A-1LDPE, HD6070EAHDPE, nucleating agent, special materials for physical foaming, etc. can all be purchased in the domestic market. PE plastic pellets are purchased by companies such as Beijing Yanshan Petrochemical Company or Xinjiang Dushanzi Petrochemical Company. Copper wires are purchased from Chengdu Shuangliu Copper Material Factory or Deyang Jingchang Copper Wire Factory. Aluminum strips are purchased from Chengdu Cable Factory Aluminum Strip Branch or Shaanxi Qinlong Company.

[0025] Process index control: product specification SYWLY-75-12, air injection aperture Ф1mm, air injection pressure 4Mpa, inner skin mold core aperture Ф2.8mm, inner skin mold sleeve aperture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com