Spray type evaporation and cooling transformer

An evaporative cooling and transformer technology, applied in the field of transformers, can solve the problem of insufficient heat absorption of the coil, and achieve the effects of reducing consumption, simple overall structure and improving economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

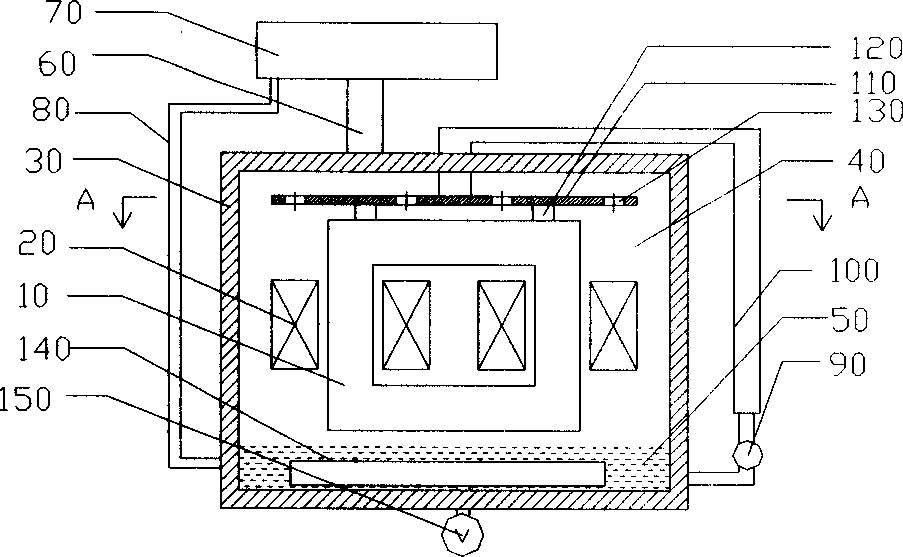

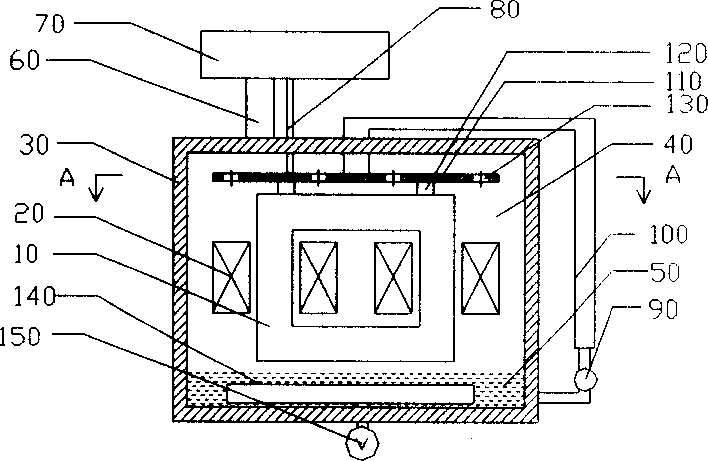

[0026] The evaporative cooling transformer of the present invention consists of an iron core 10, a coil 20, an oil tank 30, an insulating gas 40, a cooling medium 50, an intake pipe 60, a condenser 70, a liquid return pipe 80, a pump 90, a spray conduit 100, a liquid guide plate 110, and a bracket 120, a liquid guide hole 130, a resistor 140, a backup heating power supply 150, and a booster device 160.

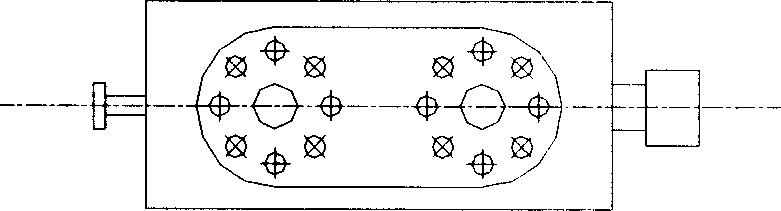

[0027] One of the specific implementations of the spray evaporative cooling transformer of the present invention is as follows: Figure 1a As shown in and b, the transformer is a single-phase transformer, the bottom of the oil tank 30 is filled with a liquid cooling medium 50, the upper part of the liquid cooling medium 50 in the oil tank 30 is filled with insulating gas 40, the upper part of the iron core 10 is connected with the lower part of the bracket 120, and the upper part of the bracket 120 is connected with the liquid guide The lower part of the plate 110 is connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com