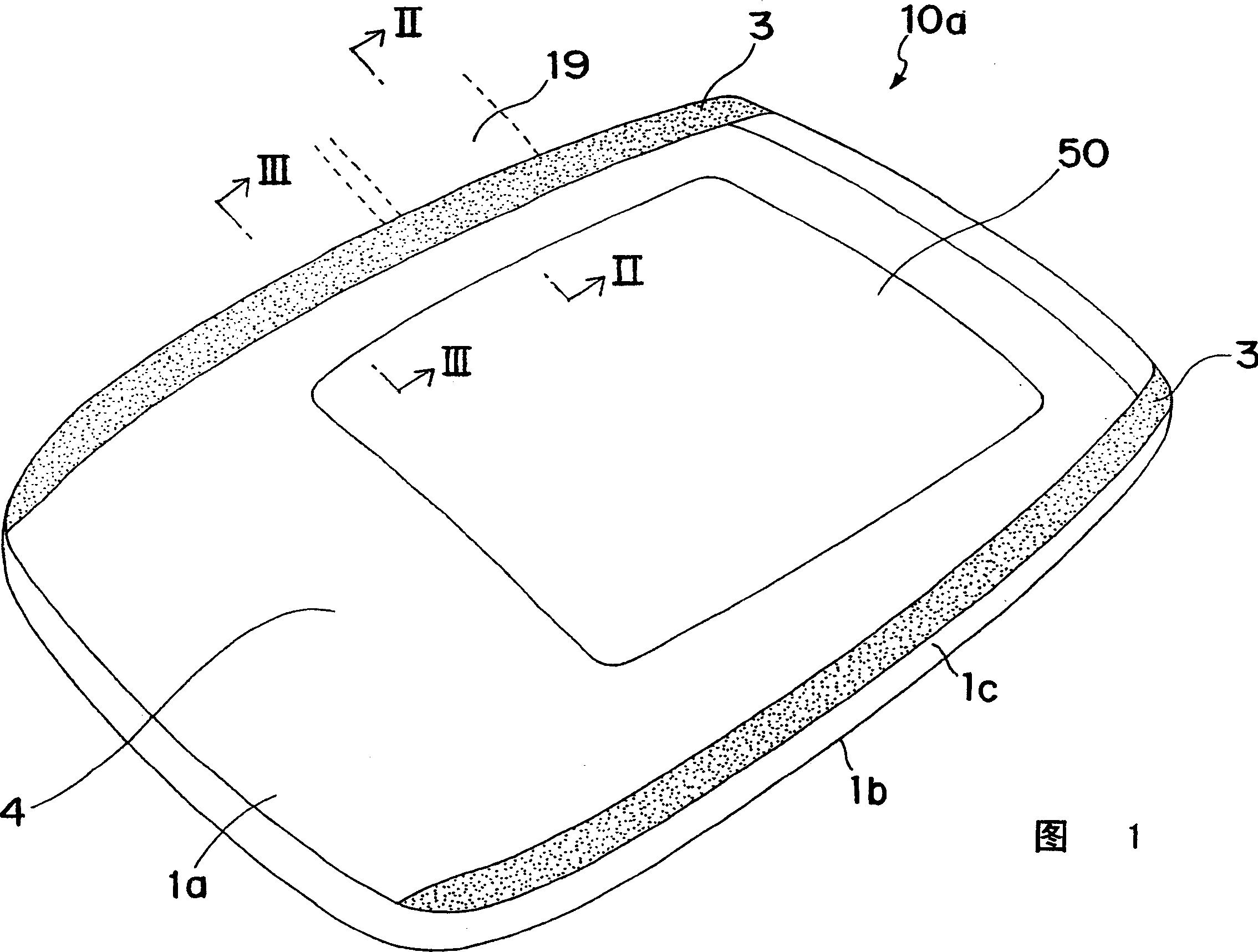

In-mold decorated molded product and method of manufacturing the same

A manufacturing method and a technology of molded products, which are applied in the field of manufacturing simultaneous decoration molded products and molded decoration molded products, can solve problems such as easy to see traces of side gates, achieve the effect of simplifying the cutting process and maintaining design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

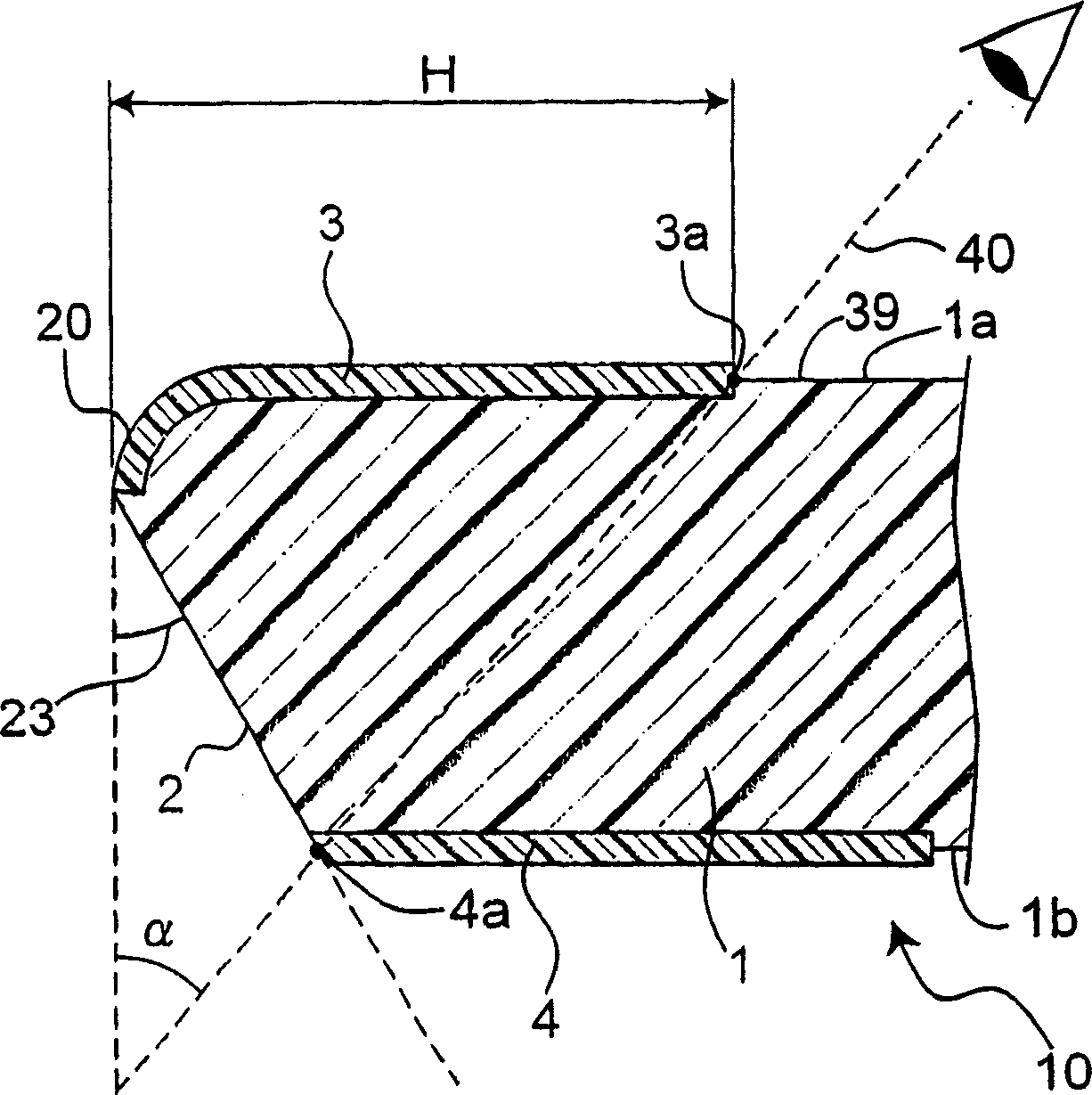

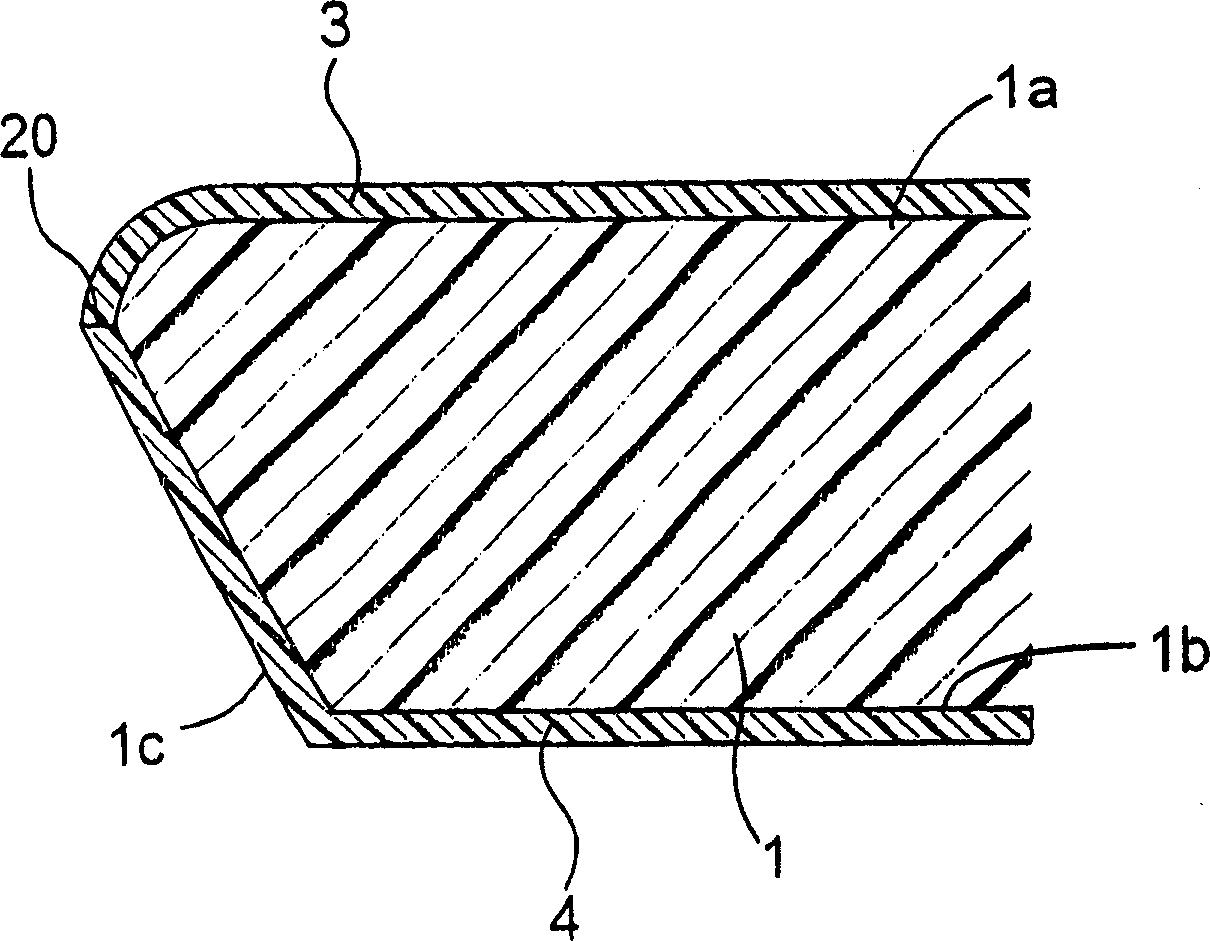

Embodiment 1

[0089] A release layer made of melamine resin is formed on a base sheet made of polyethylene terephthalate film (easy to bond) with a thickness of 38 μm, followed by two-component curing of polyurethane resin The stencil ink is used to form an evaporation anchor layer by gravure printing. After these layers were heat-treated at 120°C for 5 minutes, the first transfer layer formed by a 600±50 Å aluminum metal film was patterned by vacuum evaporation, and then formed by gravure printing. resin-formed adhesive layer to obtain a first decorative sheet. Similarly, the 2nd decorative sheet in which the 2nd transfer layer was formed was obtained.

[0090] The obtained first decorative sheet is placed in one injection molding mold so that the first transfer layer covers the end of the molded product near the side gate, and the second decorative sheet is placed in the other injection molding mold After that, inject the molding resin formed by acrylonitrile-butadiene-styrene copolymer...

Embodiment 2

[0094] On the acrylic film with a thickness of 125 μm, the first transfer layer is patterned with acrylic resin printing ink by gravure printing, and then an adhesive layer made of vinyl chloride vinyl acetate copolymer resin is formed by gravure printing to obtain the first transfer layer. 1 decorative sheet. Similarly, the 2nd decorative sheet in which the 2nd transfer layer was formed was obtained.

[0095] The obtained first decorative sheet is placed in one injection molding mold so that the first transfer layer covers the end of the molded product at the side gate, and the second decorative sheet is placed behind the other injection molding mold. After injecting molding resin made of polycarbonate, allowing it to cool and solidify, and integrating the first and second decorative sheets with the molding resin, the side gate resin forming part is cut along the side surface of the screen panel to obtain a molding At the same time, the screen panel of the mobile phone of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com