Adaptive fuel control for an internal combustion engine

A fuel control and internal combustion engine technology, applied in engine control, fuel injection control, internal combustion piston engines, etc., can solve the problems of exhaust emission impact, high total failure rate of components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

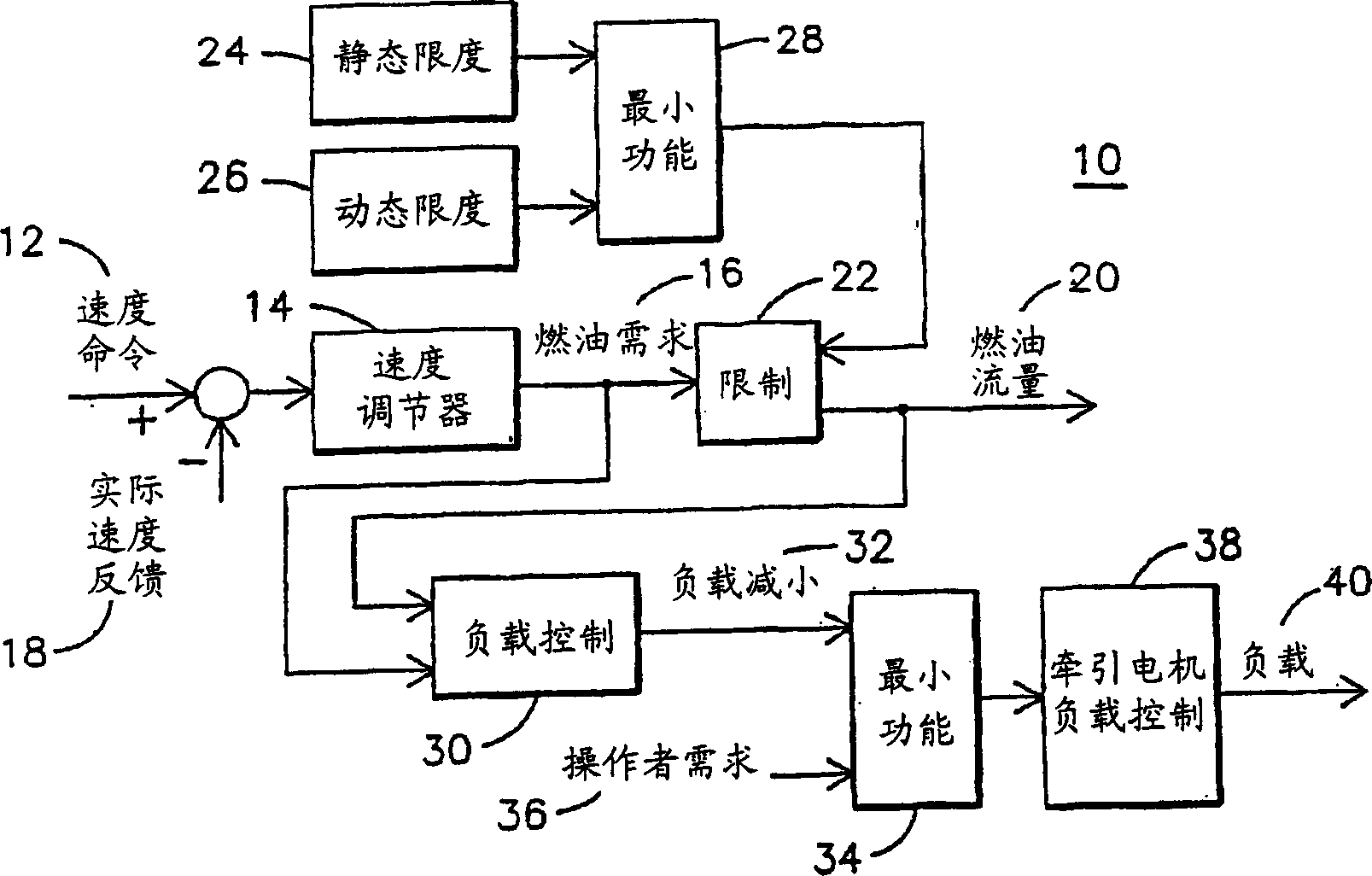

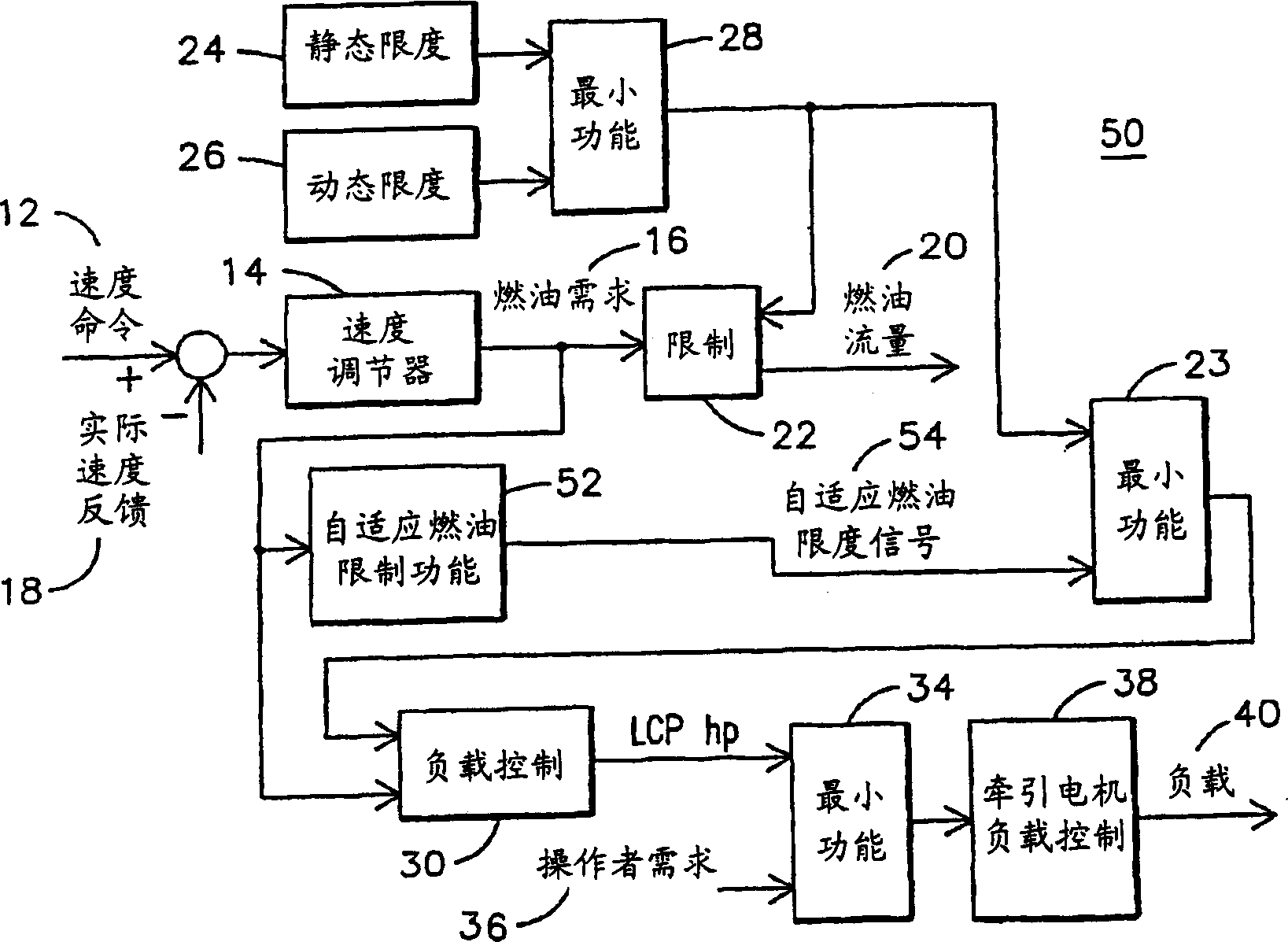

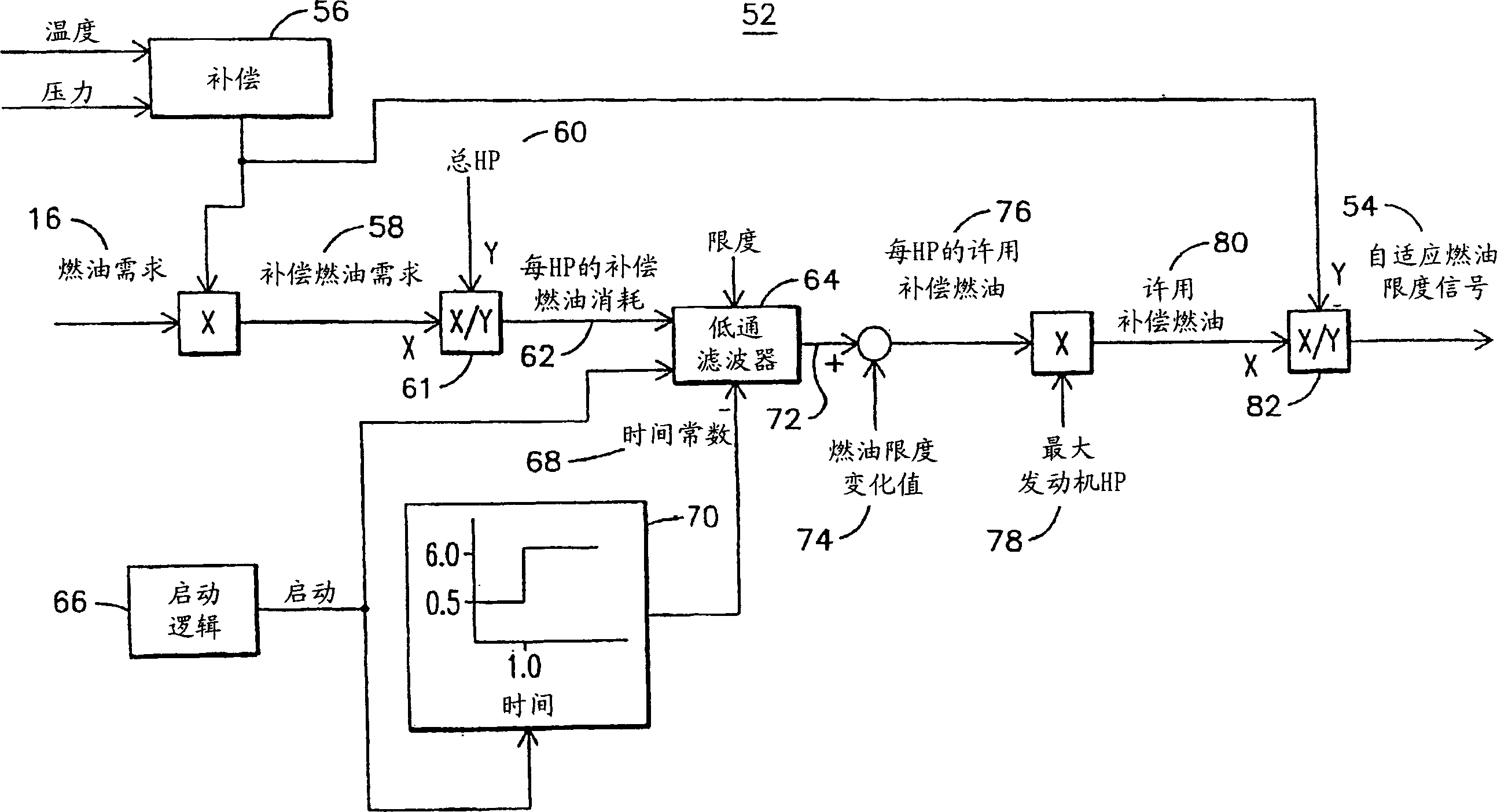

[0013] figure 2 is a block diagram of one embodiment of an improved load control system 50 that may be used in a locomotive or other electric drive system. In this system 50, the speed regulation function 14 and the fuel limit control functions 24, 26, 28 are the same as in the prior art system described in FIG. also, figure 2 The load control system 50 in includes an adaptive fuel limiting function 52 that will reduce the load on the engine, e.g., an engine cylinder or its associated Malfunction of the fuel delivery system. This reduced engine load will indirectly cause fuel flow 20 to drop. Adaptive fuel limit 52 is used to limit fuel flow 20 that may be below the limits imposed by static limit 24 and dynamic limit 26 , thereby further protecting the engine. The adaptive fuel limit function 52 varies the maximum allowable fuel flow in response to the operating history of the engine, and thus in response to a parameter indicative of engine performance versus time, as will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com