Mould for water base pulp gel injection moulding

A technology of gel injection molding and slurry, which is applied in the field of molds for injection molding, which can solve the problems of difficult demoulding, inconvenient use, and poor appearance quality of the green body, and achieve good demoulding quality, convenient processing, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

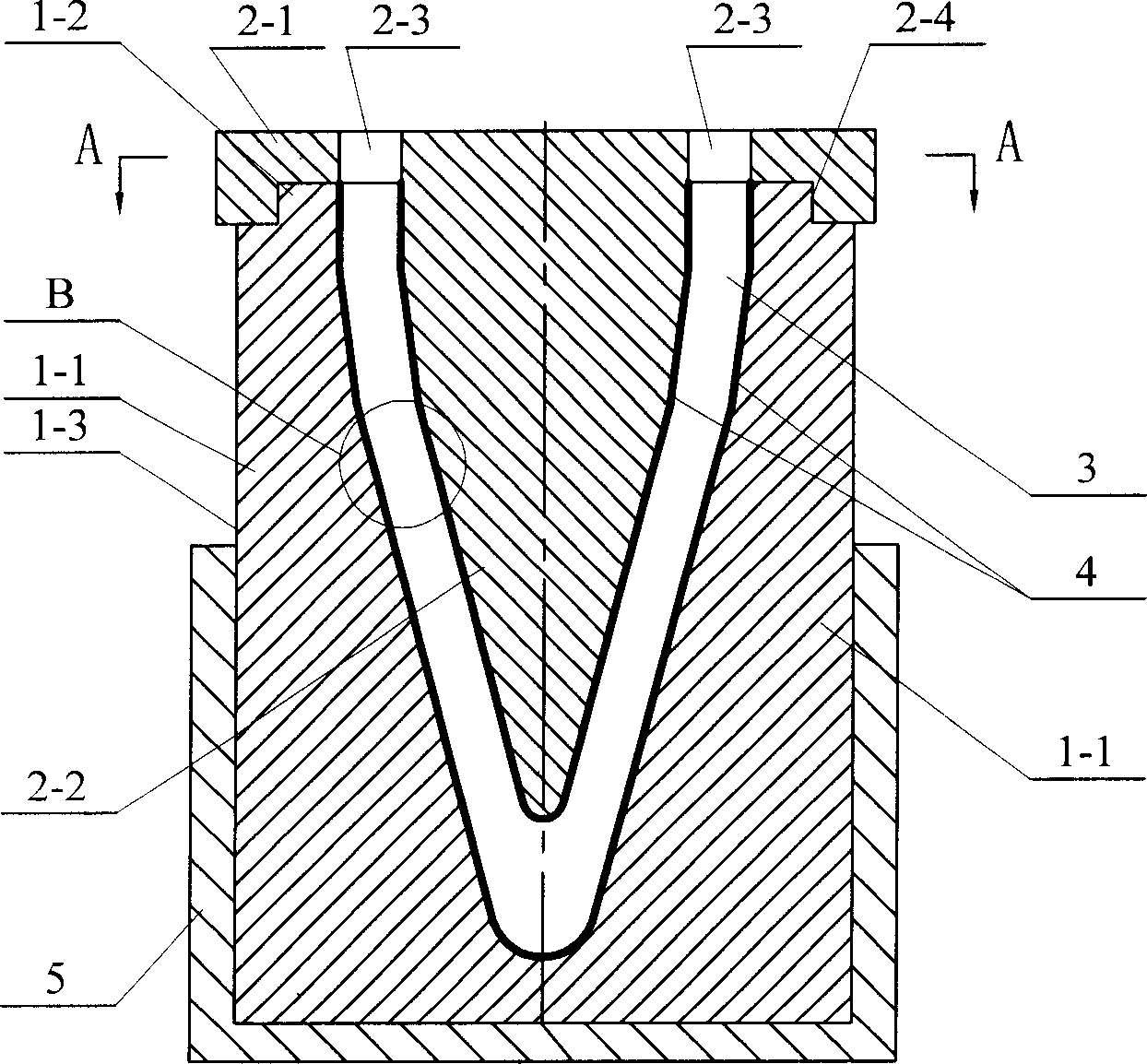

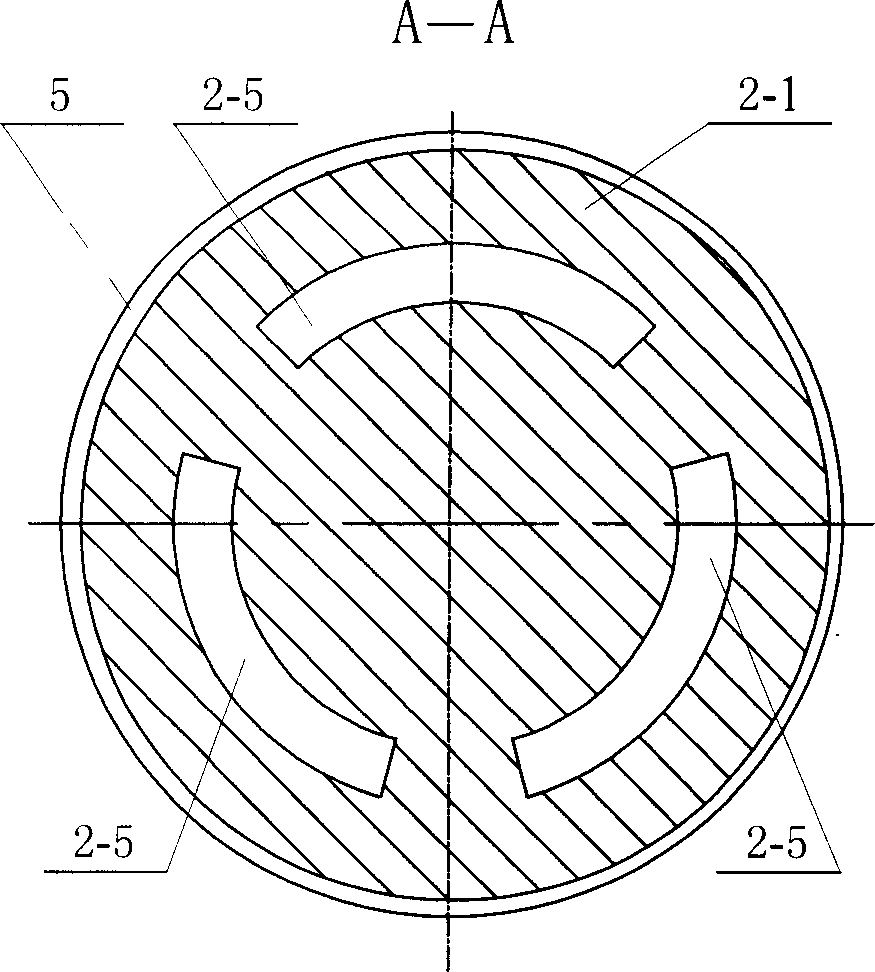

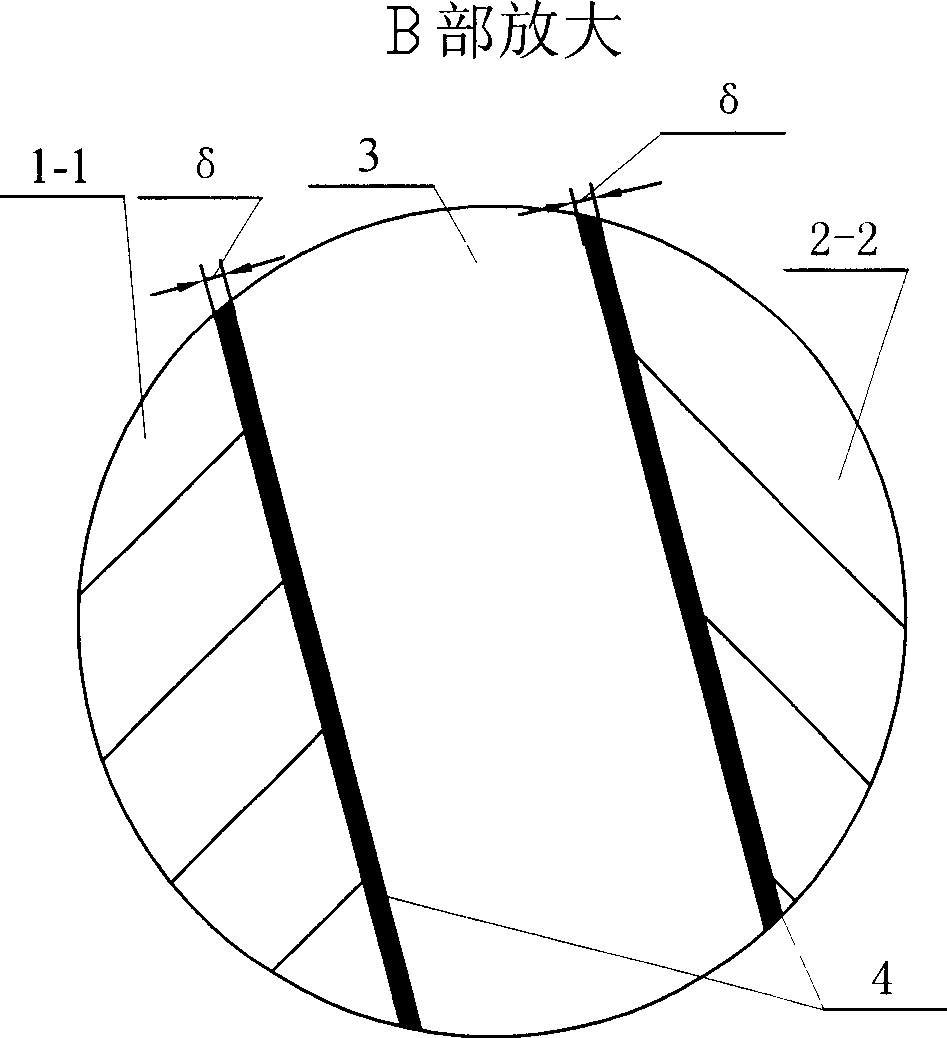

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment is made up of outer mold, mandrel, anti-adhesive coating 4 and seat cover 5; Described mandrel is made of gland 2-1 and mold core integrated with gland 2-1 2-2, the mold core 2-2 is installed in the inner cavity of the outer mold, and the annular channel 3 is formed by the mold core 2-2 and the inner cavity of the outer mold, and the anti-sticking coating 4 is respectively arranged on the mold core 2 -2 and the surface of the inner cavity of the outer mold, the gland 2-1 is fixedly connected with the outer mold, the gland 2-1 is provided with a slurry inlet 2-3 communicating with the annular channel 3, and the outer The mold is composed of two symmetrically placed half molds 1-1, the lower end of the outer mold is installed in the seat cover 5, the outer end surface of the outer mold is a cylinder 1-3, and the outer mold and the core mold are made of graphite materia...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment one is: the mold core 2-2 of this embodiment and the described outer mold cavity are respectively bullet-shaped, and the mold core 2-2 is contained in the outer mold In the cavity, the annular channel 3 formed by the mold core 2-2 and the inner cavity of the outer mold is in the shape of a bullet. The above-mentioned structure can meet the requirement of making working parts of the ceramic radome.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the upper end of the outer mold of this embodiment is provided with cylindrical protrusion 1-2, and the lower end of described gland 2-1 is provided with the cylindrical protrusion 1-2 of described outer mold. The matching cylindrical inner hole 2-4, the cylindrical protrusion 1-2 of the outer mold is installed in the cylindrical inner hole 2-4 of the gland 2-1, the inner cavity of the outer mold and the mold core 2-2 coaxial. By adopting the above structure, the core mold and the outer mold can be closely combined, thereby ensuring the concentricity of the core mold and the outer mold. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com