Two-stage unloading pilot-controlled check valve for hydraulic support pole

A technology of hydraulic support column and hydraulic control check valve, which is applied in the direction of control valve, support/support, valve device, etc., can solve the problem of not meeting the requirements of high-end product support moving speed, erosion resistance, pollution resistance and impact resistance Poor performance, inconvenient installation and underground maintenance, etc., to achieve the effect of convenient installation and maintenance, avoid destructive impact, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

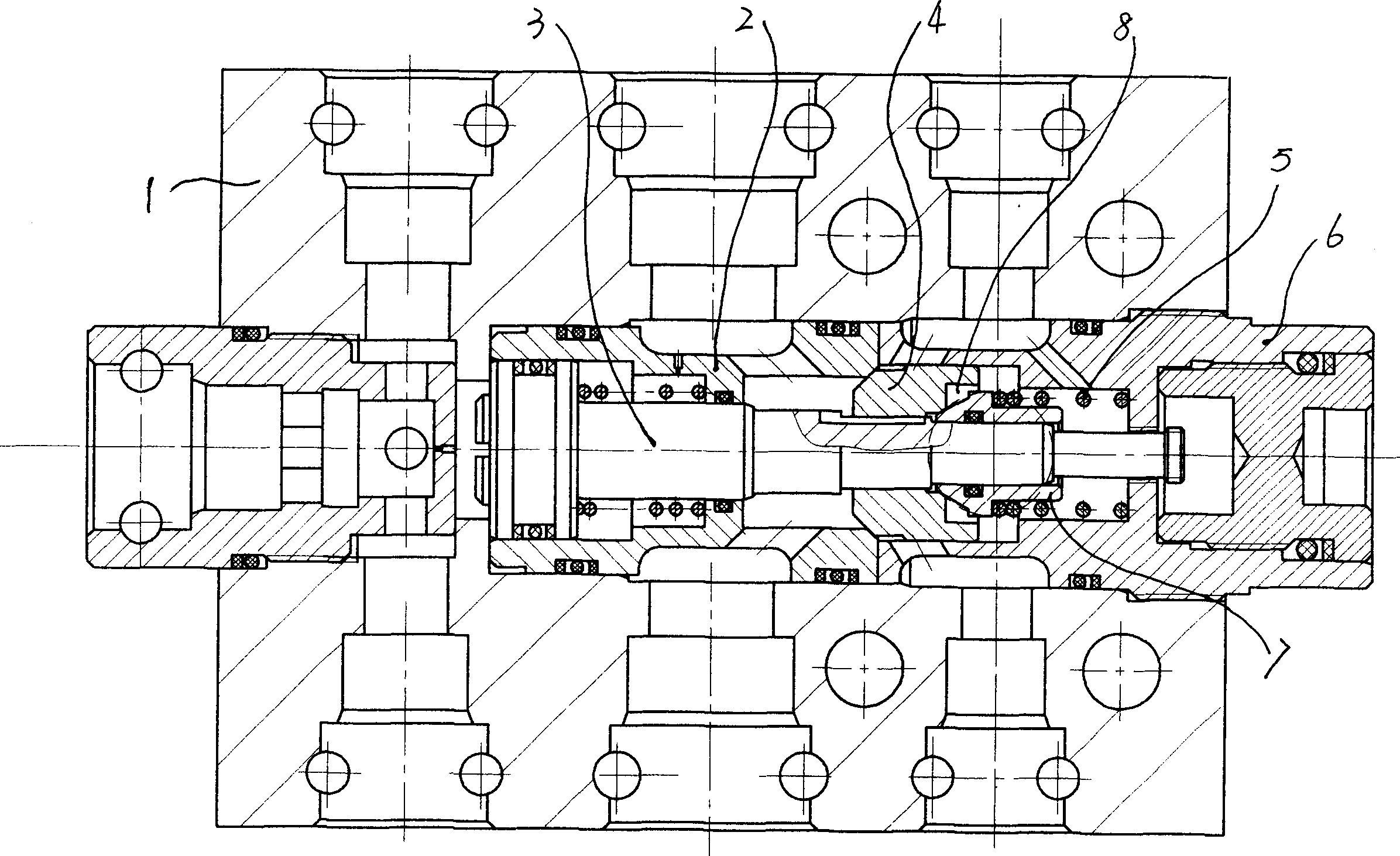

[0009] As shown in the figure, the two-stage unloading hydraulic control check valve for the hydraulic support column according to the present invention includes a valve body 1 with a valve cavity and a liquid inlet and outlet, and a valve set in the valve cavity Seat 2, and the large spool 4 that fits tightly with the valve seat 2 and fits on the valve stem 3, the return spring 5, and the valve sleeve 6 connected to the end of the valve stem 3, the large spool 4 The sealing surface between the valve seat 2 and the valve seat 2 is a stainless steel metal sealing surface; a small valve core 7 is set on the valve stem 3, and the small valve core 7 is tightly matched with the valve seat cavity 8 set on the large valve core 4 , the sealing surface is stainless steel metal sealing surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com