Thermal depolarization compensation resonant cavity of high power E-O Q-switch solid laser

A technology of solid-state lasers and laser resonators, applied in the field of laser resonators, can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

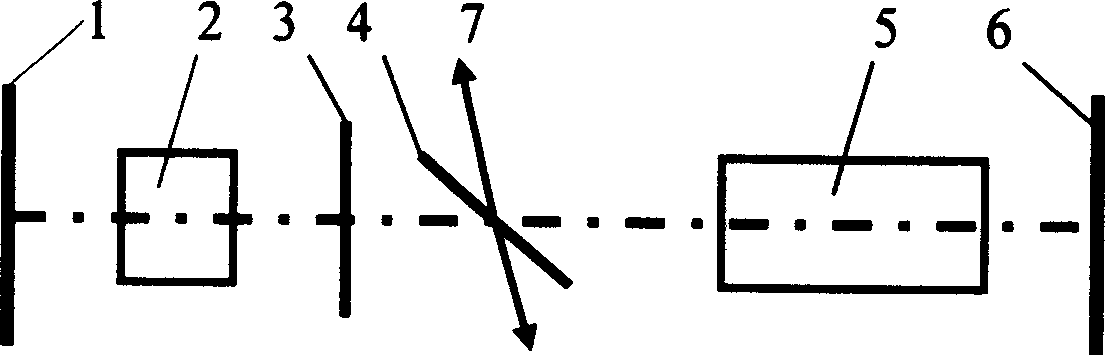

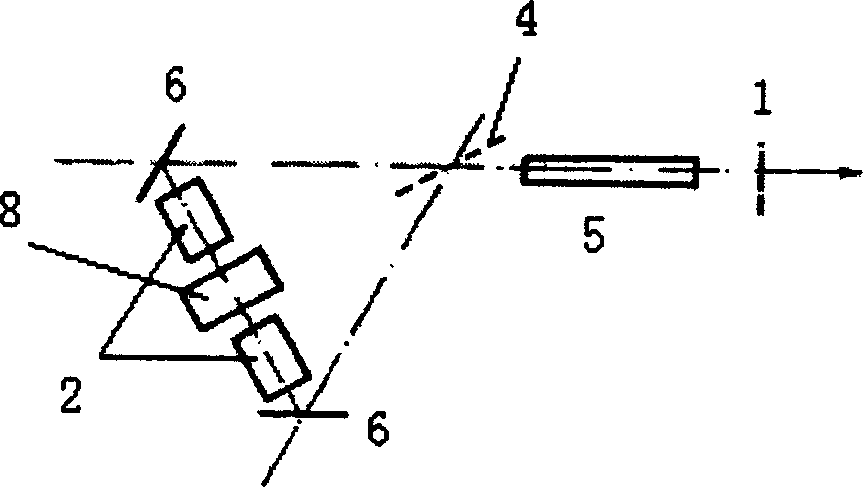

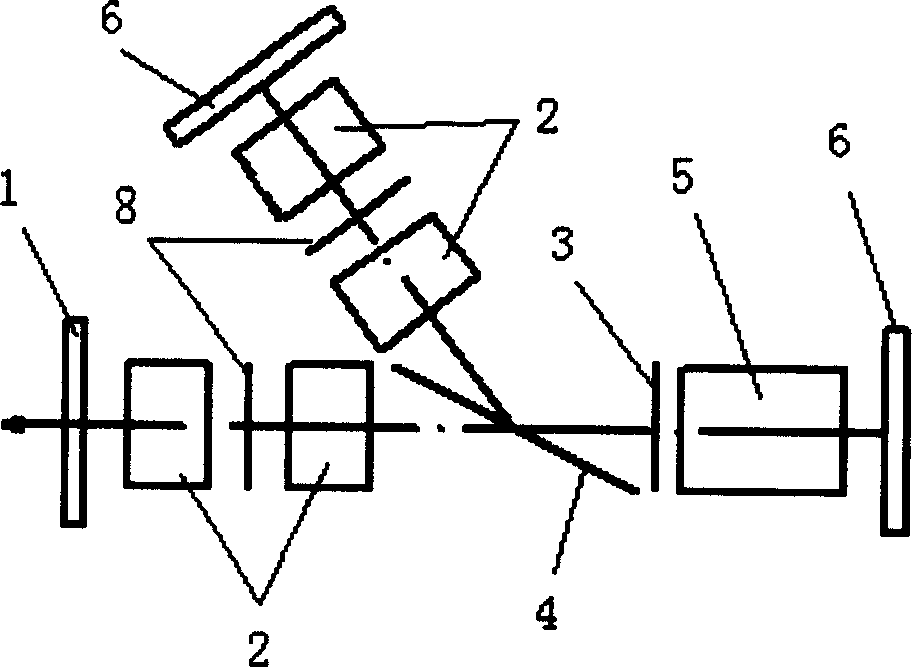

[0016] see image 3 , image 3 It is a structural schematic diagram of the thermal depolarization compensation resonator of the high-power electro-optic Q-switched solid-state laser of the present invention, as can be seen from the figure, the thermal depolarization compensation resonator of the high-power electro-optic Q-switched solid-state laser of the present invention includes an output mirror 1, a laser medium 5 and the laser resonator that total reflection mirror 6 forms, on the optical axis of described laser resonator, from described laser medium 5 to output mirror 1, be provided with a λ / 4 wave plate 3, a polarizer 4 and A first electro-optic Q switch composed of two Pockels boxes 2 clamping a 90-degree quartz polarization rotator 8, the polarizer 4 forms a Brewster angle with the optical axis, the first electro-optic Q switch and The output mirror 1 forms the first polarization branch, and in the other direction of the Brewster angle with the polarizer 4, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com