Natural material imitation furnature weaving material its prodn. method

A woven material and a natural imitation technology, applied in the field of imitation natural furniture woven materials and their manufacturing, can solve the problems of difficulty in imitating the color and texture of natural materials, unfavorable processing and high processing costs, and achieve the goal of being environmentally friendly and not easy to fall off. The effect of paint fading and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The imitative natural furniture weaving material of the present embodiment is mainly made of the following raw materials in parts by weight: 95 parts of PE (polyethylene), 5 parts of PP (polypropylene), and 5 parts of colorants. The raw materials of this embodiment also have conventional Metered foaming agent, stabilizer and other general auxiliary materials in the industry. On the surface of the material, there are textures or patterns that are different from the base color of the material, have a visual effect close to natural materials, and are regularly or irregularly distributed.

Embodiment 2

[0018] The imitation natural furniture weaving material of this embodiment is mainly made of the following raw materials in parts by weight: 98 parts of PE, 2 parts of PP, 3 parts of colorant, and the raw materials of this embodiment also have conventionally measured foaming agent and stabilizer General auxiliary materials in other industries. On the surface of the material, there are textures or patterns that are different from the base color of the material, have a visual effect close to natural materials, and are regularly or irregularly distributed.

Embodiment 3

[0020] The natural-like furniture weaving material of this embodiment is mainly made of the following raw materials in parts by weight: 96 parts of PE, 4 parts of PP, and 4 parts of colorants. The raw materials of this embodiment also have conventionally measured foaming agents and stabilizers. General auxiliary materials in other industries. On the surface of the material, there are textures or patterns that are different from the base color of the material, have a visual effect close to natural materials, and are regularly or irregularly distributed.

[0021] The method for manufacturing the natural-like furniture weaving material comprises the steps of:

[0022] 1) Prepare the raw materials according to the ratio and mix them evenly. According to the color of the pigment, mix them into a mixture of the corresponding color; during the mixing process of the materials, the foaming agent will become gas and volatilize.

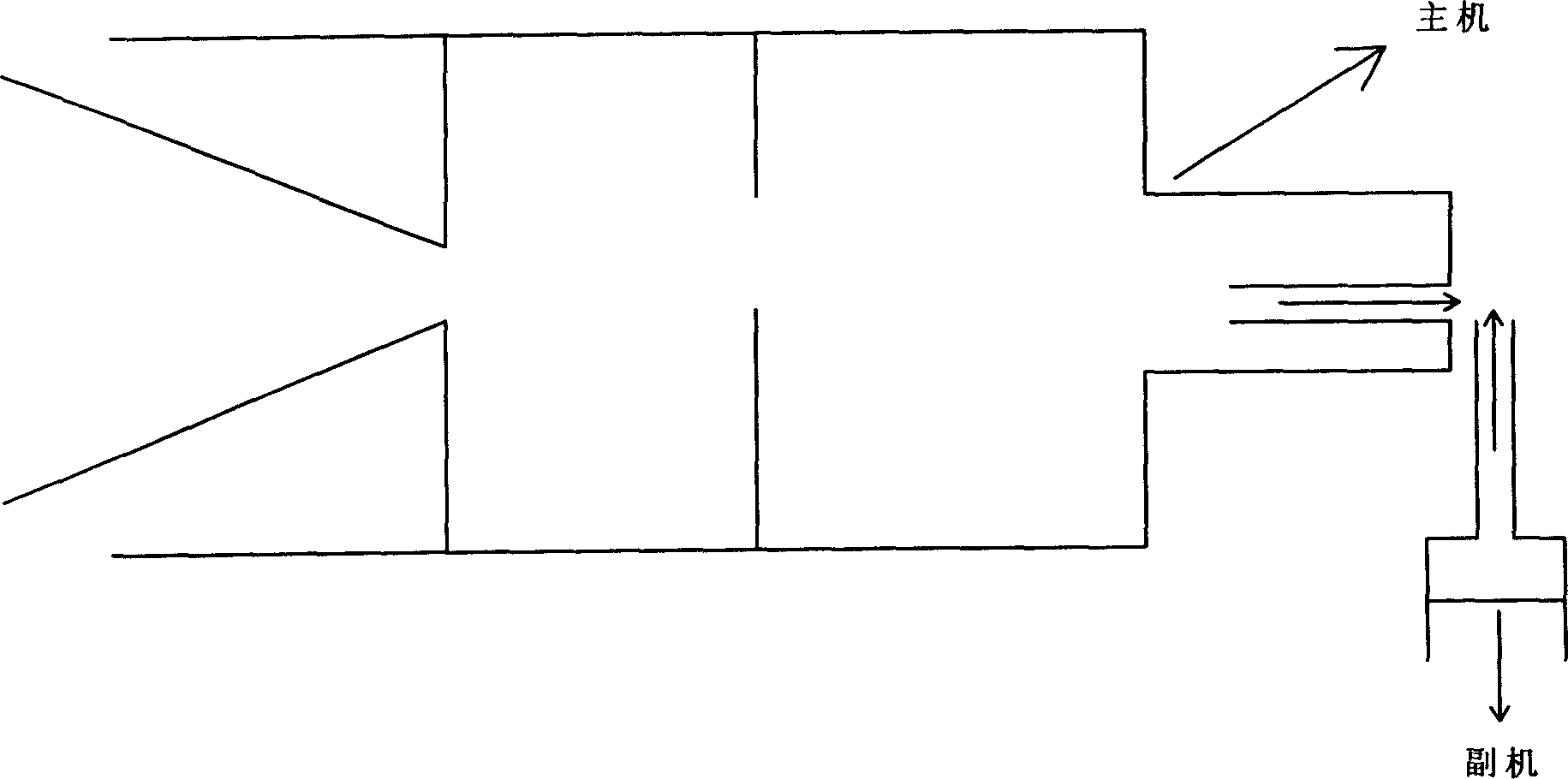

[0023] 2) Add a mixture of one color to the main machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com