Thermosyphon and method of manufacturing the same

A thermosiphon and outer tube technology, applied in heating methods, household heating, sustainable buildings, etc., can solve the problems of decreased heating efficiency or cooling efficiency, high manufacturing cost of thermosiphon, and low qualified rate of cover materials, etc. Achieve the effect of reducing heat transfer loss, simple fixing operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

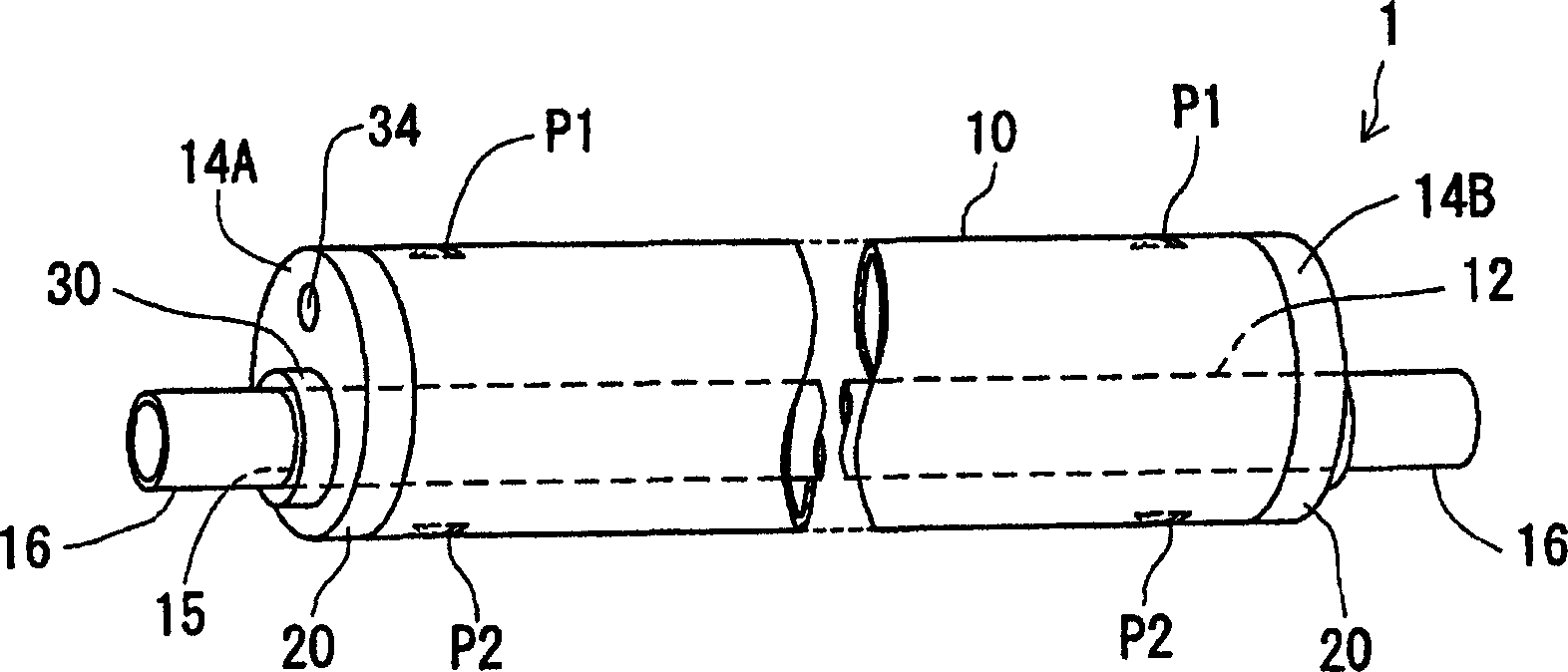

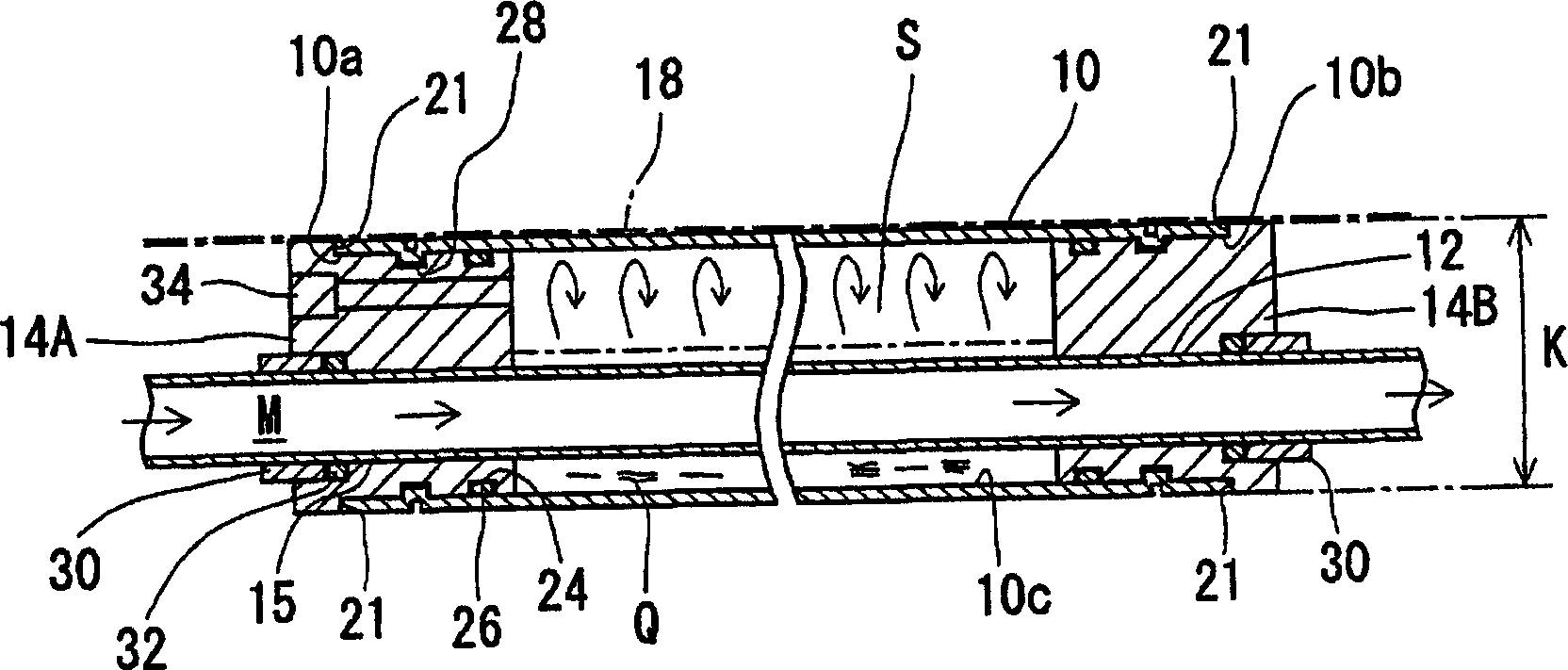

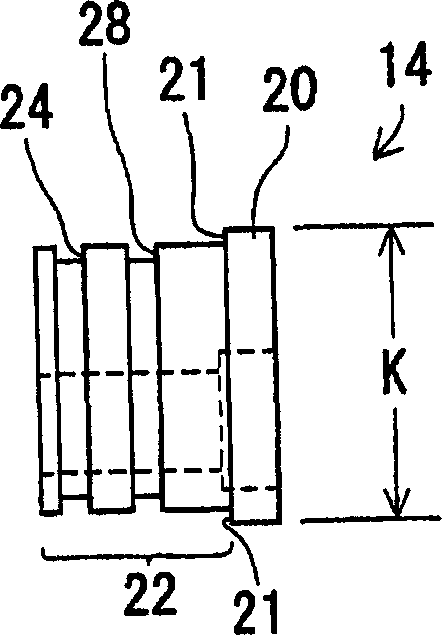

[0037] Hereinafter, embodiments of the thermosiphon device of the present invention will be described with reference to the drawings, together with a method of manufacturing the same. In the thermosiphon device of the present invention, the inner pipe used for the flow of the heat source fluid M is penetrated in the outer pipe, and the working fluid (medium) in the outer pipe is subjected to high-speed evaporation and condensation cycles by using the warm and cold heat from the heat source fluid. Heat, heat transfer device for heating or cooling around the outer tube. In particular, in this embodiment, the thermosiphon device is applied to, for example, a device for underground heating that is installed under the ground of a building with multiple connections in a horizontal type, and that supplies warm heat source fluid from a heat source device to heat the room. The situation is described as an example.

[0038] Figure 1 to Figure 8 shows the thermosiphon device 1 of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com