Manufacturing method and device of organic electroluminescent device

A technology of electroluminescent devices and manufacturing methods, applied in the direction of electroluminescent light sources, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., to achieve the effect of preventing thermal expansion and accurate position alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

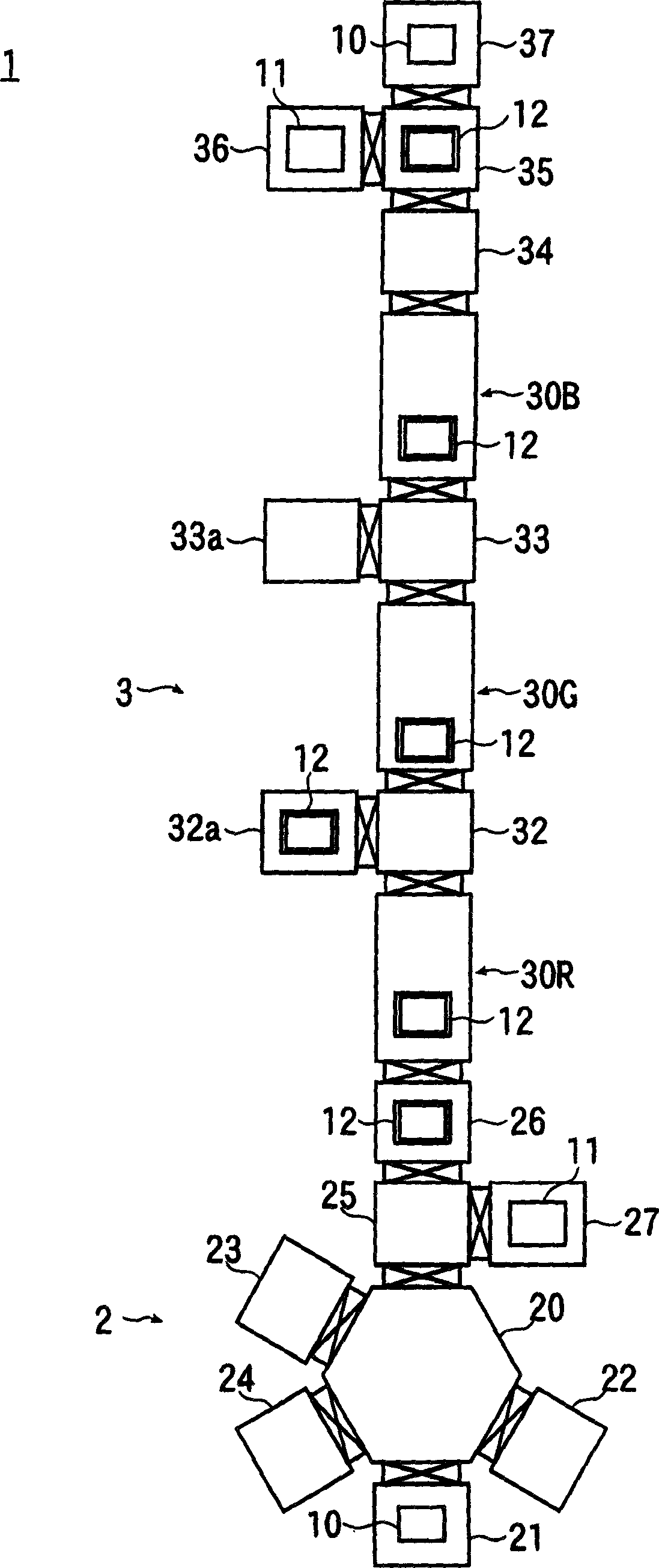

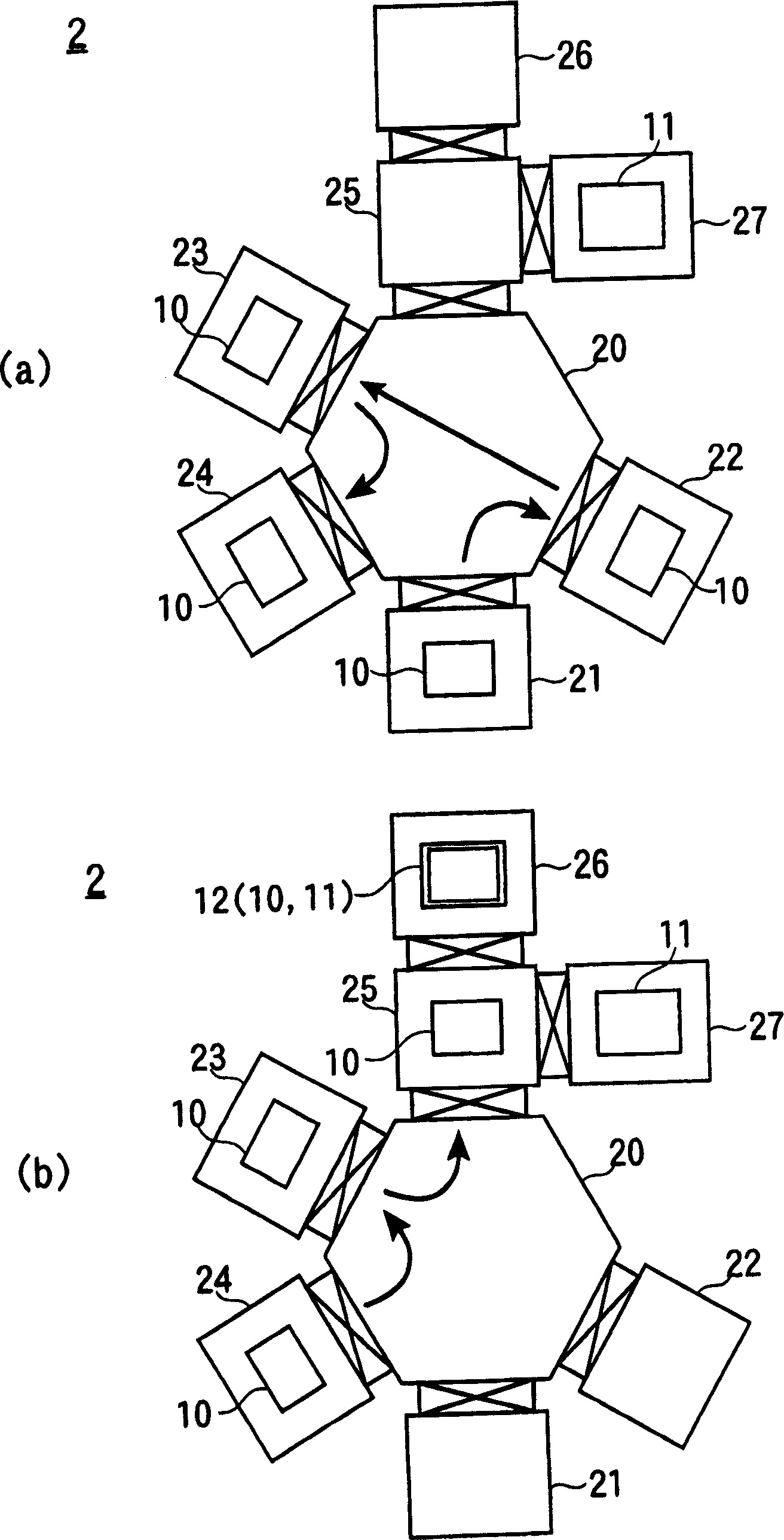

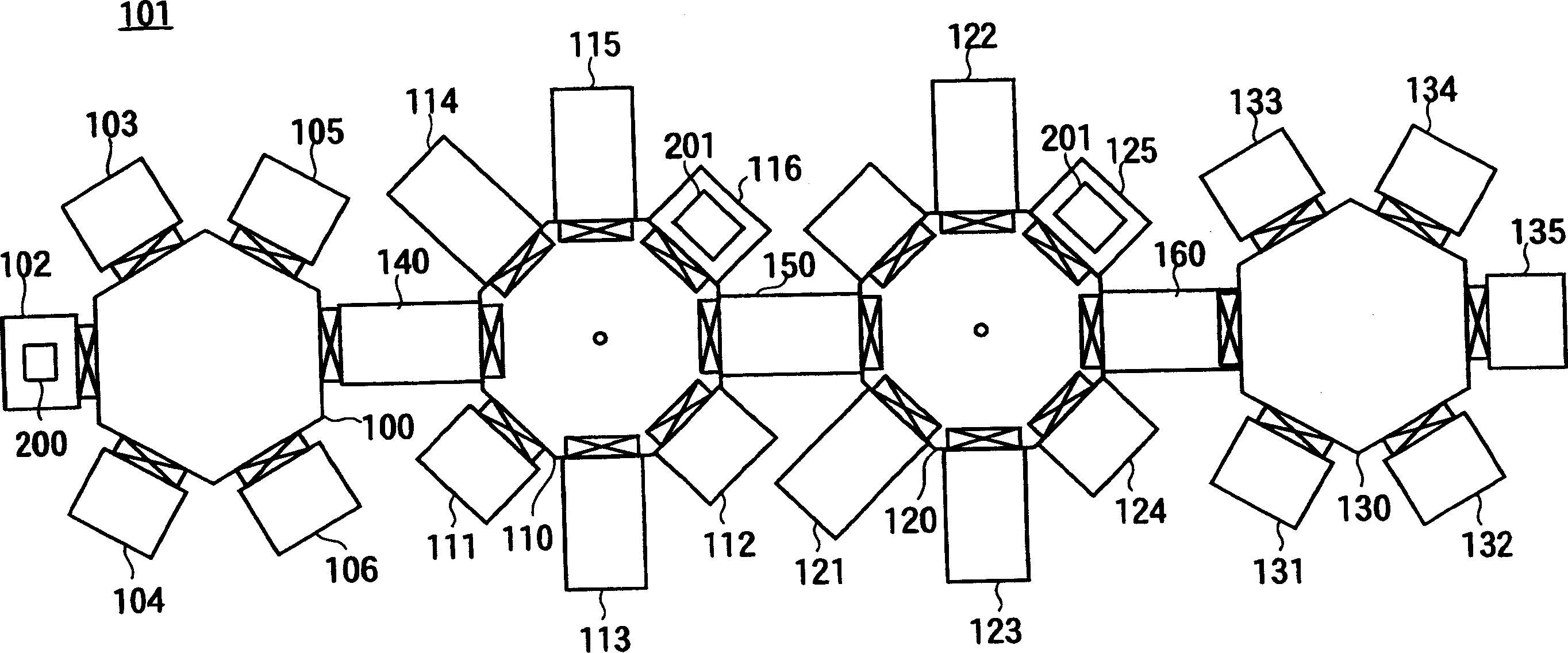

[0023] figure 1 is a schematic configuration diagram of main parts showing the first embodiment of the organic electroluminescent device manufacturing apparatus of the present invention, figure 2 (a), figure 2 (b) is a schematic configuration diagram showing the processing flow of the preprocessing unit in this embodiment.

[0024] Such as figure 1 As shown, the organic electroluminescent device manufacturing apparatus 1 of the present embodiment has: a preprocessing part 2 for performing pretreatment on a substrate 10; an organic light emitting layer forming part (organic light emitting layer forming part) layer forming part) 3.

[0025] Each chamber described later of the preprocessing unit 2 and the organic light-emitting layer forming unit 3 is connected to an unillustrated vacuum exhaust system, and is configured to transfer the substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com