Multi-freedom ring stator supersonic dynamo

An ultrasonic motor, annular stator technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Difficult to control the size, limited application range and other problems, to achieve the effect of solving the problem of pre-pressure application, compact structure and wide application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

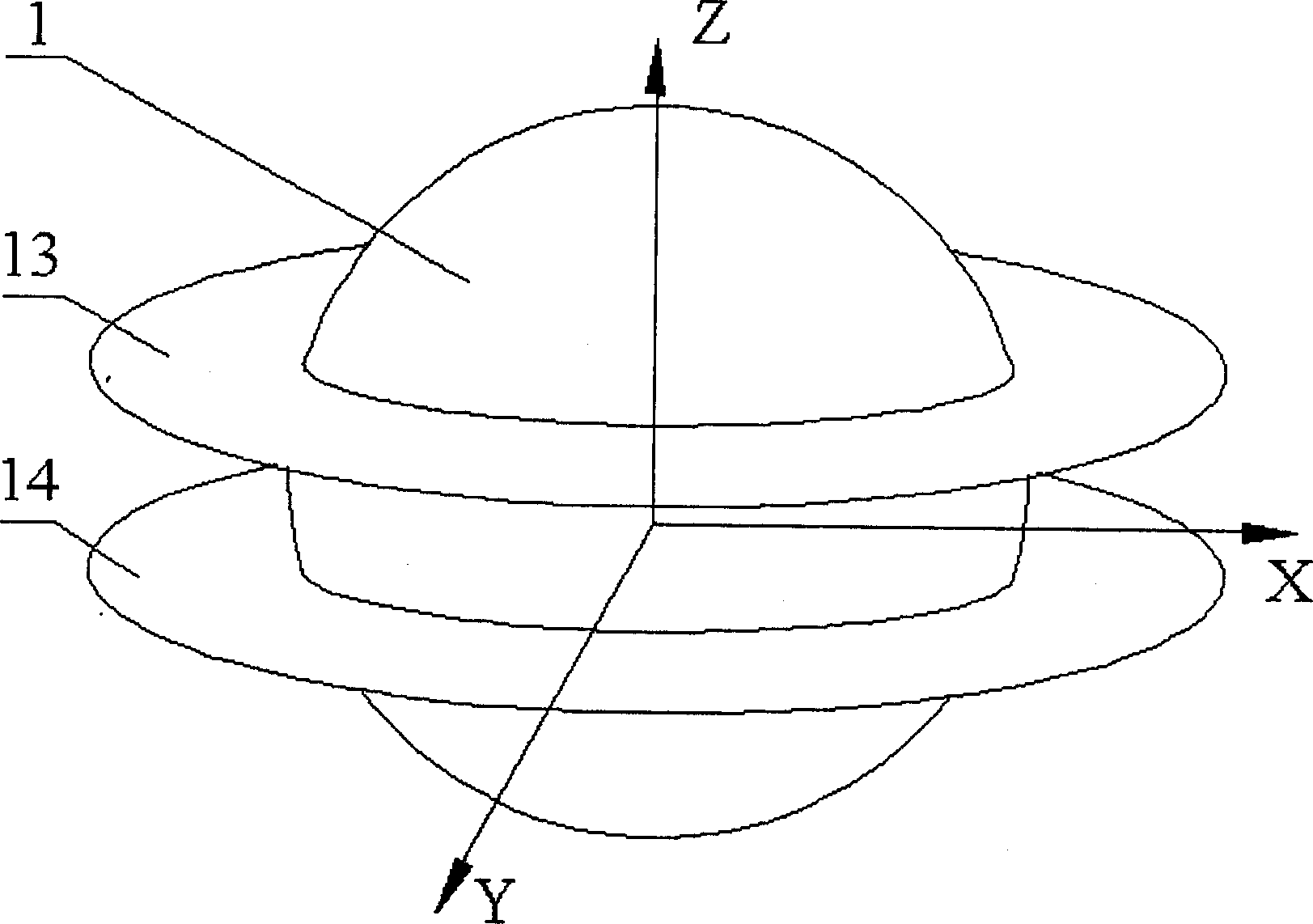

[0027] In the following, taking n=2, that is, the 16 sector-shaped electrode partitions of the piezoelectric ceramic ring, as an example, the working principle and specific implementation of the multi-degree-of-freedom ultrasonic motor of the ring stator are described.

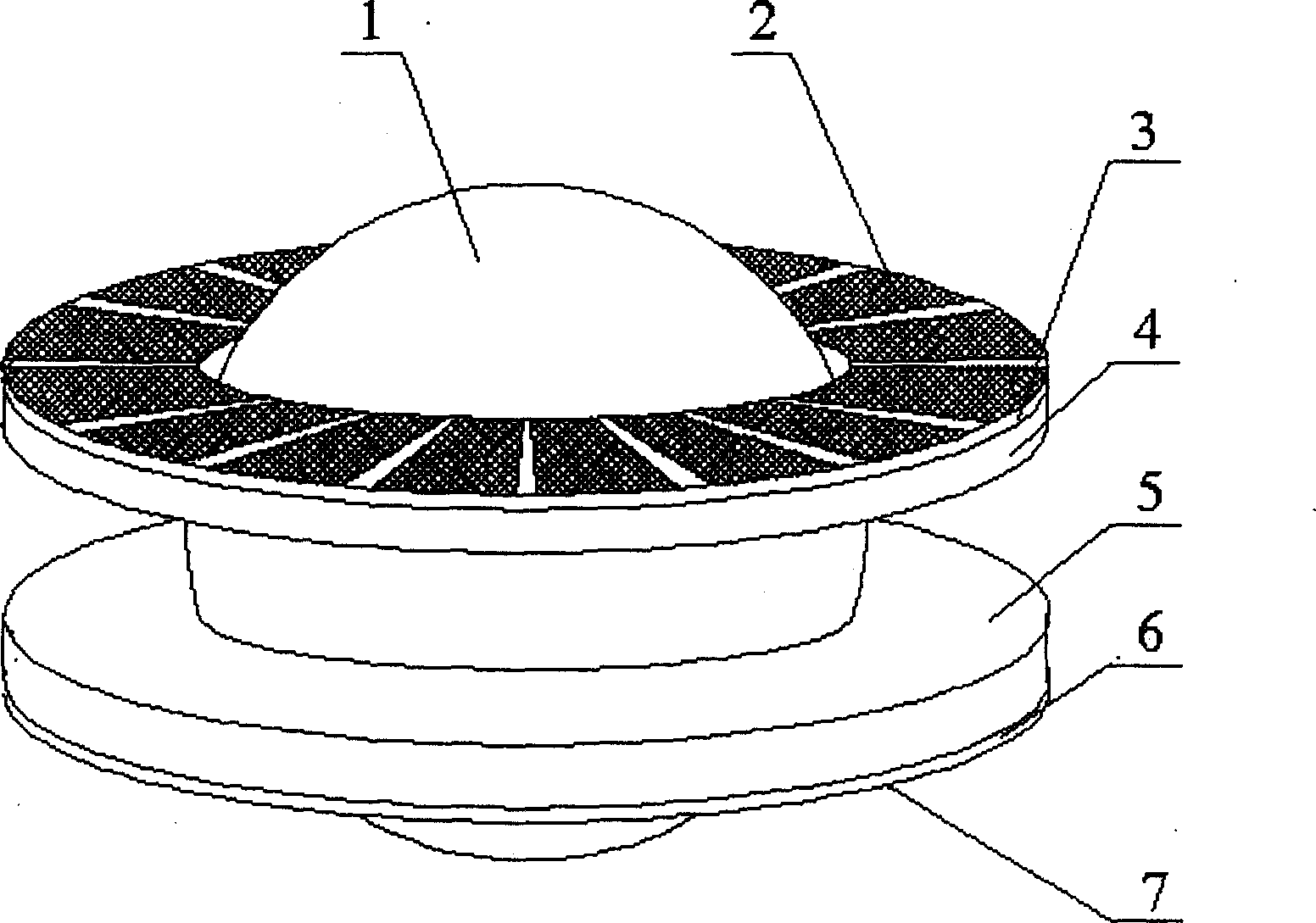

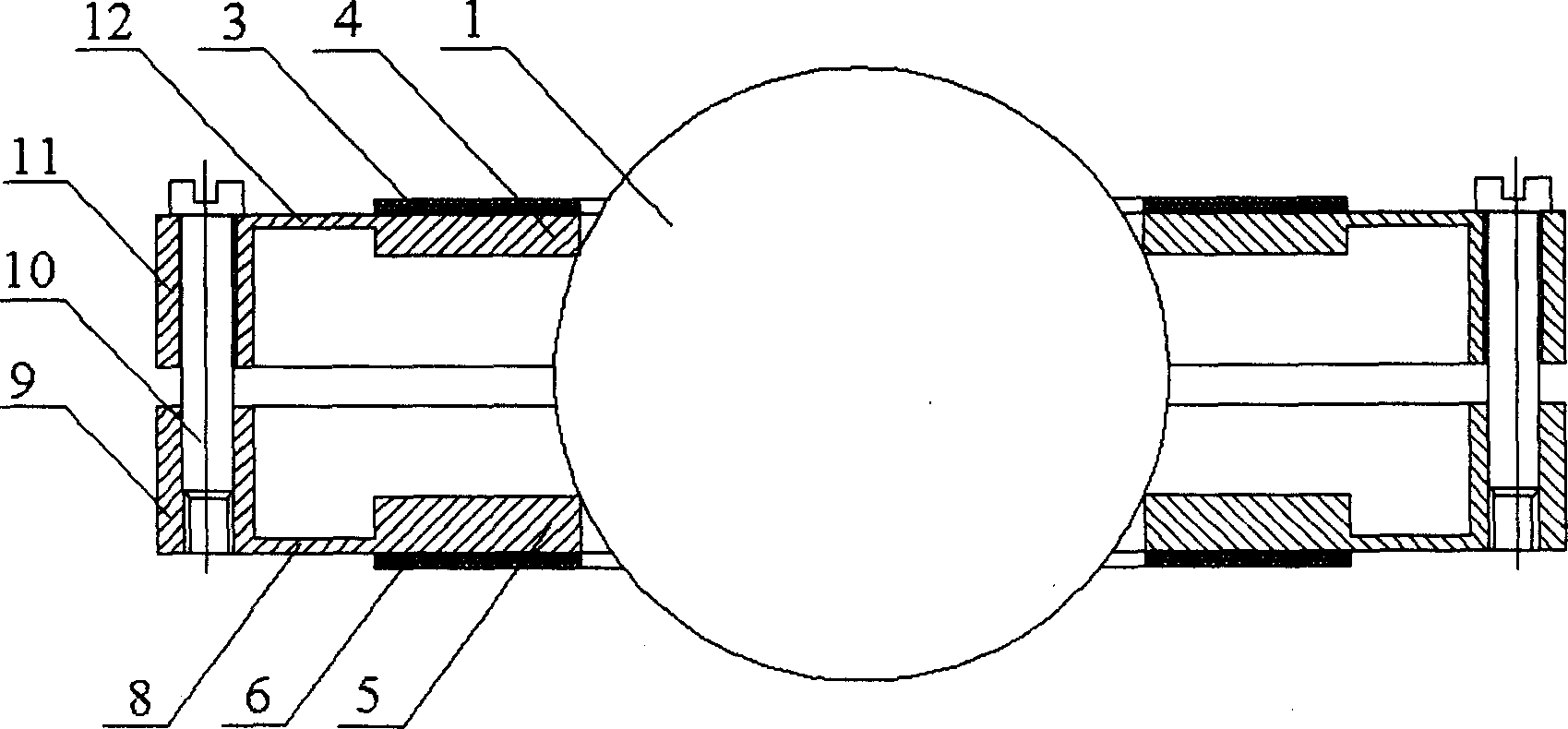

[0028] Such as figure 1 , figure 2 As shown, the annular stator multi-degree-of-freedom ultrasonic motor of the present invention is mainly composed of a stator assembly, a rotor and a bracket assembly. In the stator assembly, a pair of upper piezoelectric ceramic rings 3 and lower piezoelectric ceramic rings 6 which are unidirectionally polarized in the axial direction are respectively pasted on the non-opposing surfaces of a pair of opposed upper stator rings 4 and lower stator rings 5. The surfaces of the upper piezoelectric ceramic ring 3 and the lower piezoelectric ceramic ring 6 are respectively plated with 16 evenly divided sector electrodes 2 and 7 sector electrodes. The spherical rotor 1 is clamped betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com