Counter-pressure filling device and method for counter-pressure filling

A filling equipment and back pressure technology, which is applied in the field of back pressure filling equipment, can solve the problem that the filling nozzle is not equipped with a sealing device, and achieve the effect of saving time and money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

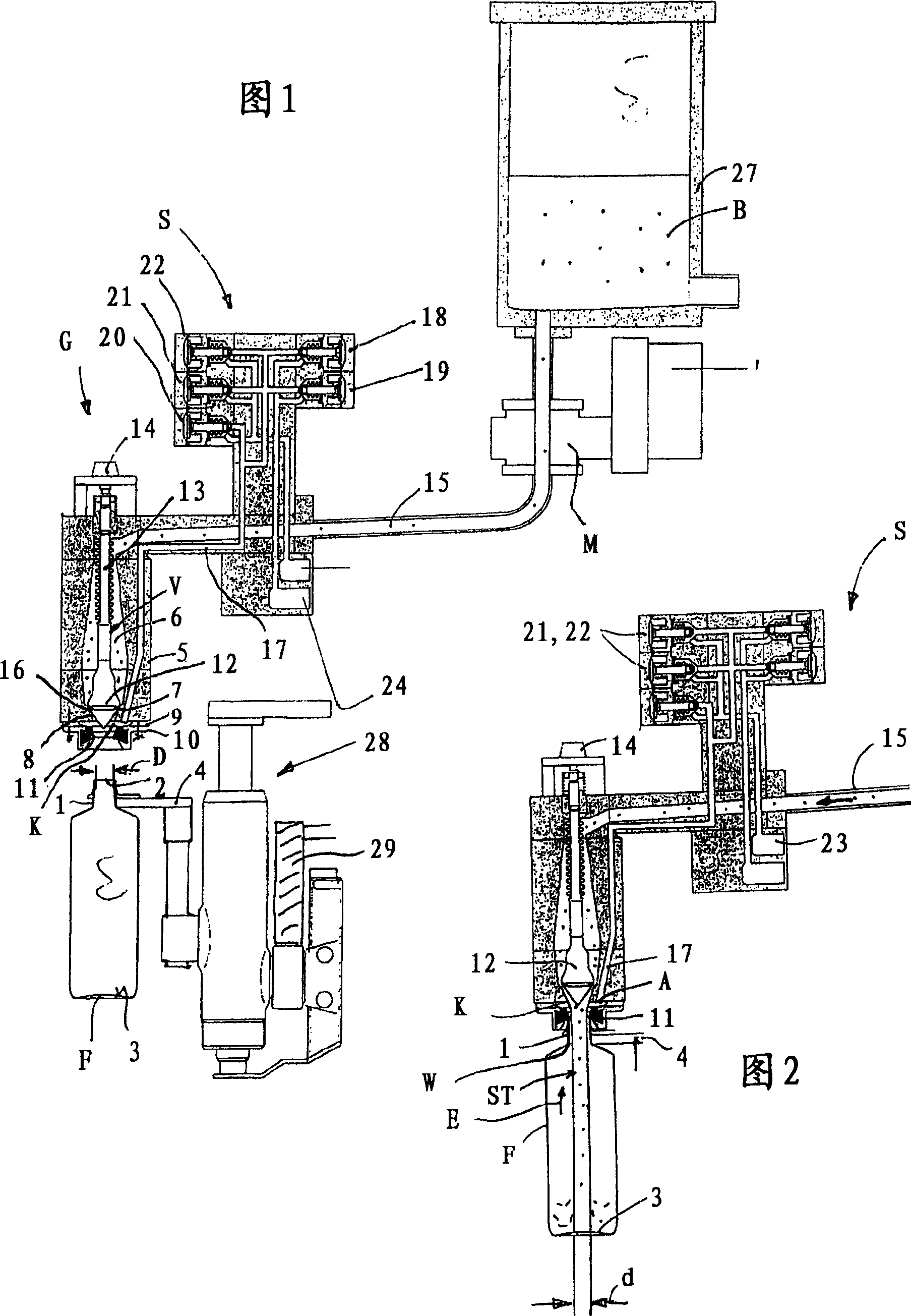

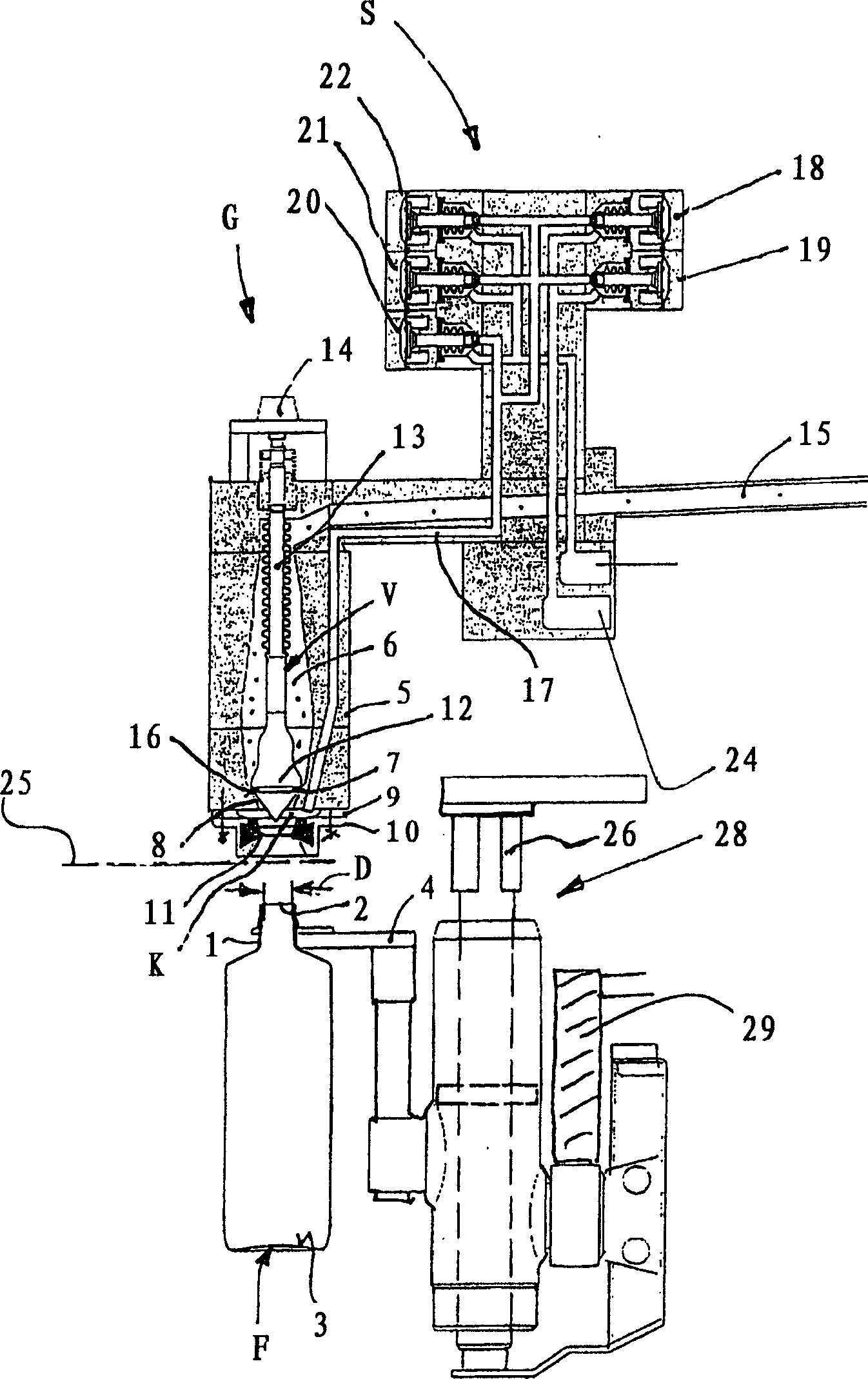

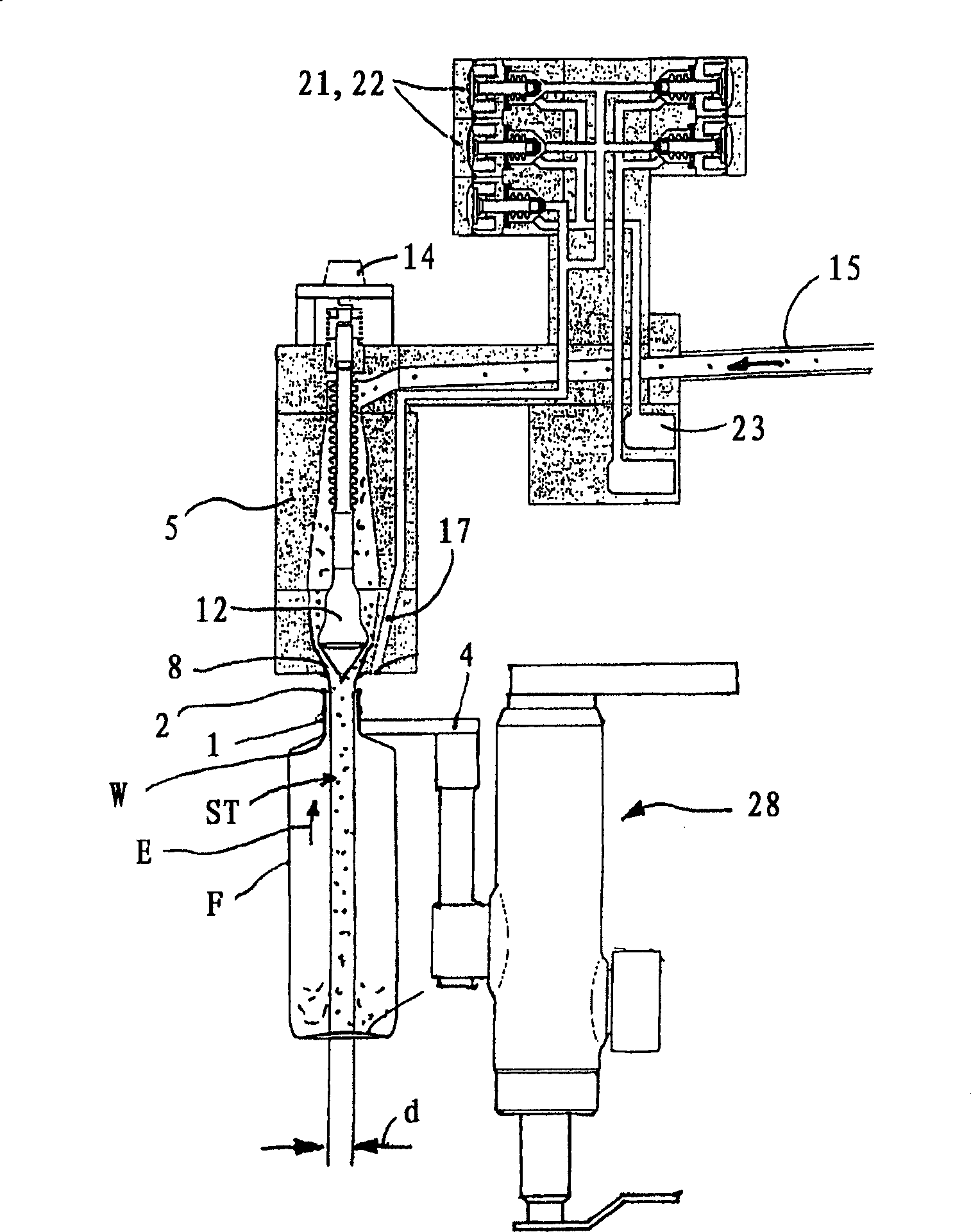

[0028] A back pressure filling device G shown in partial section in FIGS. Drink B under pressure. For gas-containing beverages, it can be understood here as a beverage that contains CO 2 , O 2 , N 2 or a similar gas or mixture of gases, typically beer.

[0029] However, the backpressure filling device G can be comfortably and quickly switched over to filling still beverages, such as still mineral water, milk or the like, without backpressure.

[0030] Each bottle F to be filled has a neck 1 with an upper, here circular, opening 2 and a base 3 , which is, for example, convex in the center. The inner diameter D of the bottle neck 1 and the bottle mouth 2 is, for example, 21 mm.

[0031] For filling, the bottle F is gripped by a holding and pressing device 4 , for example under a support ring, at the bottle neck 1 and lifted from the position shown in FIG. 1 under a housing 5 .

[0032] A filling chamber 6 is formed in the housing 5 , in which a closure part V is arranged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com