Infrared double-frequency chalcogenide glass ceramics and method for preparing same

A technology of chalcogenide glass and frequency doubling, applied in the field of chalcogenide glass ceramics and its preparation, to achieve the effects of short production cycle, no deliquescence, easy processing and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

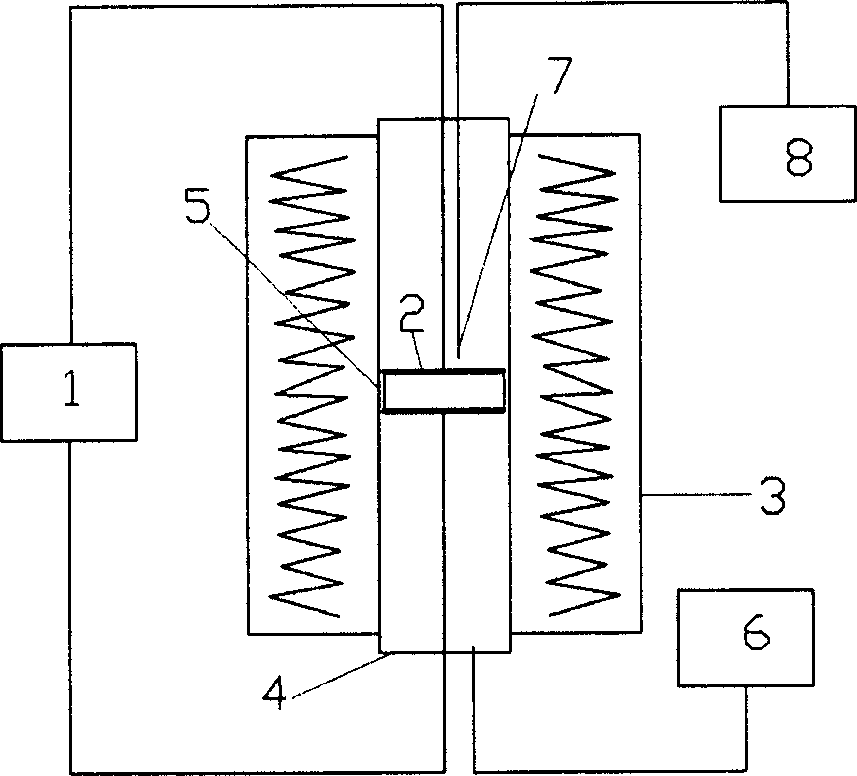

Method used

Image

Examples

Embodiment 1

[0027] Infrared frequency doubling chalcogenide glass ceramics components by mole percentage are: GeS 2 , 70; Ga 2 S 3 , 15; CdS, 15.

[0028] The specific preparation method is as follows:

[0029] 1). Select raw materials.

[0030] 2). In an environment full of inert gas (such as a glove box), Ga 2 S 3 , CdS and GeS 2The raw materials are mixed, and after being ground and mixed to make batches, they are placed in containers (such as quartz glass tubes, etc.) and vacuumized for 10 -4 ~10 -6 Pa, and then fusing the container (quartz glass tube, etc.) and placing it in a heating device (swing furnace).

[0031] 3). When heating the container containing the batch material in step 2), first slowly raise the temperature to 595°C-605°C, keep it at this temperature for 3 hours, and then slowly raise the temperature to 945°C at a rate of less than 3°C / min. ℃-955℃, heat preservation for 10 hours, after standing for 1 to 3 hours, quench (2 to 5 seconds) the container containin...

Embodiment 2

[0036] Infrared frequency doubling chalcogenide glass ceramics components by mole percentage are: GeS 2 , 90; Ga 2 S 3 , 5; CdS, 5.

[0037] The specific preparation method is as follows:

[0038] 1). Carry out according to 1) of embodiment 1.

[0039] 2). Carry out according to embodiment 1-2).

[0040] 3). When heating the container containing the batch material in step 2), first slowly raise the temperature to 595°C-605°C, keep it at this temperature for 5 hours, and then slowly raise the temperature to 945°C at a rate of less than 3°C / min. ℃-955℃, keep warm for 10 hours, let it stand for 1 to 3 hours, pass the air (10 to 60 seconds) into the container filled with glass liquid, and then immediately put it into the annealing furnace heated to 430℃, after the annealing is completed, slice, Polished to obtain the base glass.

[0041] 4). Put the glass sheet prepared in step 3) into a crystallization furnace with an additional electric field and an inert atmosphere protec...

Embodiment 3

[0043] Infrared frequency doubling chalcogenide glass ceramics components by mole percentage are: GeS 2 , 60; Ga 2 S 3 , 20; CdS, 20.

[0044] The specific preparation method is as follows:

[0045] 1). Carry out according to 1) of embodiment 1.

[0046] 2). Carry out according to embodiment 1-2).

[0047] 3). When heating the container containing the batch material in step 2), first slowly raise the temperature to 595°C-605°C, keep it warm at this temperature for 3-5 hours, and then slowly raise the temperature at a rate of less than 3°C / min To 945°C-955°C, keep warm for 15 hours, let it stand for 1-3 hours, then quench the container containing the glass liquid through ice-water mixture (2-5 seconds), and then immediately put it into the annealing furnace heated to 400°C After the annealing is completed, slice and polish to obtain the basic glass.

[0048] 4). Put the glass sheet prepared in step 3) into a crystallization furnace with an additional electric field and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com