Sand cushion-free pre-compacting water-draining consolidation method for soft soil foundation

A sand-free cushion, drainage consolidation technology, applied in the direction of basic structure engineering, soil protection, construction, etc., can solve the problems of extended construction period, inability to enter the site for construction, and prone to subsidence of mechanical equipment, so as to save construction costs, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The following are the construction steps of this technology:

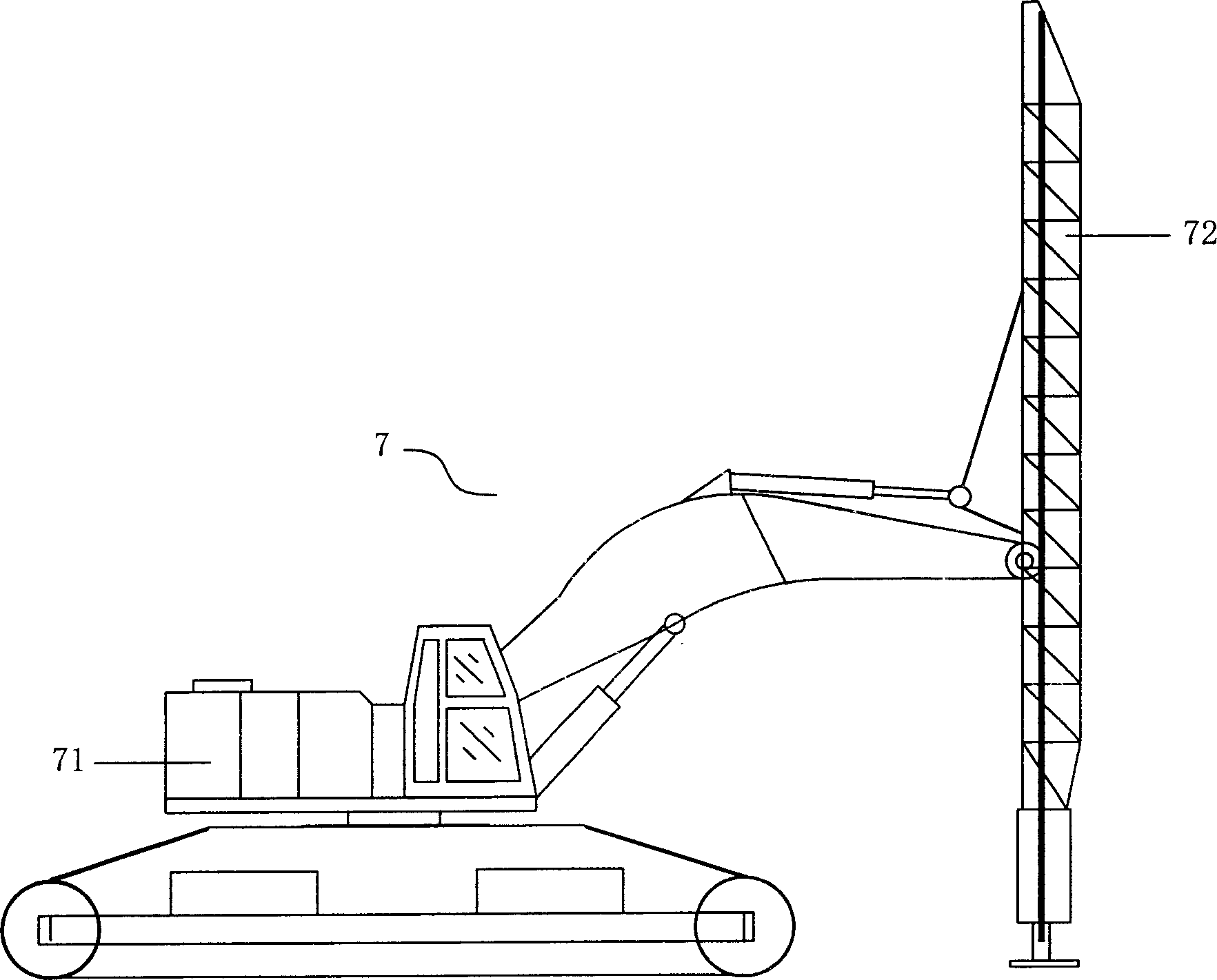

[0017] 1. Determine the insertion depth of the plastic drainage board according to the thickness of the soft soil layer and the design requirements of the project, and at the same time use the applicable silt insertion machine 7 according to the bearing capacity of the foundation. Such as figure 1 As shown, the mud inserting machine 7 is composed of walking equipment and a pile frame. The walking equipment is modified from an amphibious excavator 71, and the pile frame 72 is made by welding angle steel. The model of the excavator is based on the bearing capacity of the mud surface and the height of the pile frame. Considering other factors comprehensively, the pile frame can be assembled by itself.

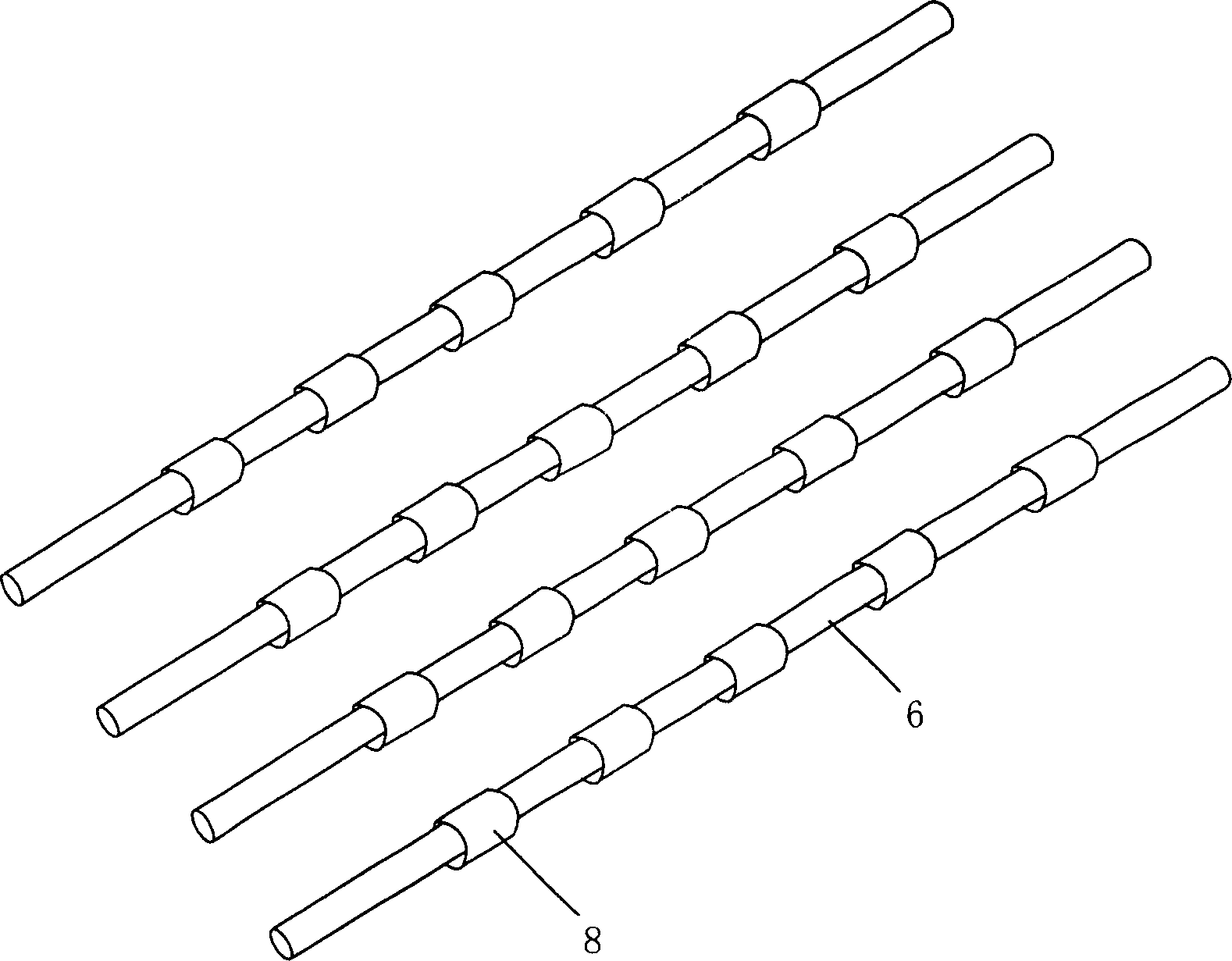

[0018] 2. According to the design requirements, select the corresponding drainage board model, and use bamboo sticks or waste drainage board cores to stake out. The layout of the drainage board 8 can be plum-s...

Embodiment 2

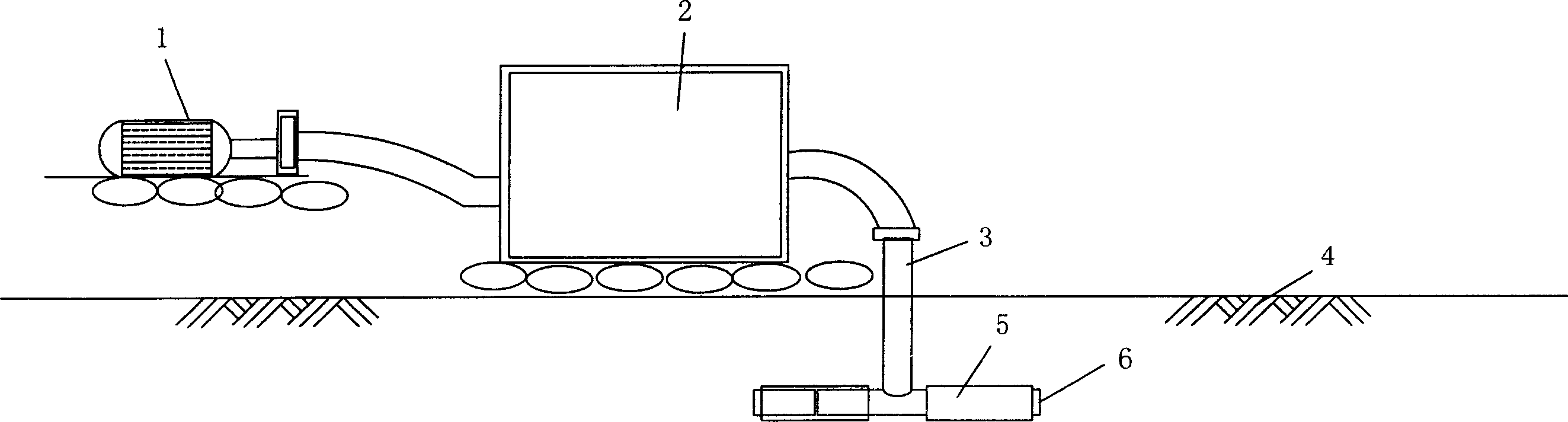

[0023] After completing steps 1 to 4 as in Example 1, carry out surcharge preloading construction.

[0024] After the 6 rows and columns of the horizontal drainage pipelines are connected, surcharge construction is carried out on it. The surcharge is applied in layers and compacted in layers. The first layer of surcharge uses loose materials such as stone powder to avoid damage to the drainage board and drain pipes.

Embodiment 3

[0026] After completing steps 1 to 4 as in Example 1, carry out vacuum combined surcharge preloading construction. After vacuuming and constant loading for about 10 days, carry out heaping construction on the sealing film 4 . In order to protect the sealing film 4, a layer of non-woven geotextile is firstly laid on it, and fine particle materials such as silt and fine sand are used as the first-stage stockpiling material, and the stockpiling is filled in layers and compacted in layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com