Oil scraper ring ring groove arrangement for pistons of internal combustion engines

A technology for oil scraping rings and internal combustion engines, which is applied to piston rings, mechanical equipment, engine components, etc., can solve problems such as engine wear, and achieve the effects of reducing production costs, reducing axial height, and increasing tangential force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

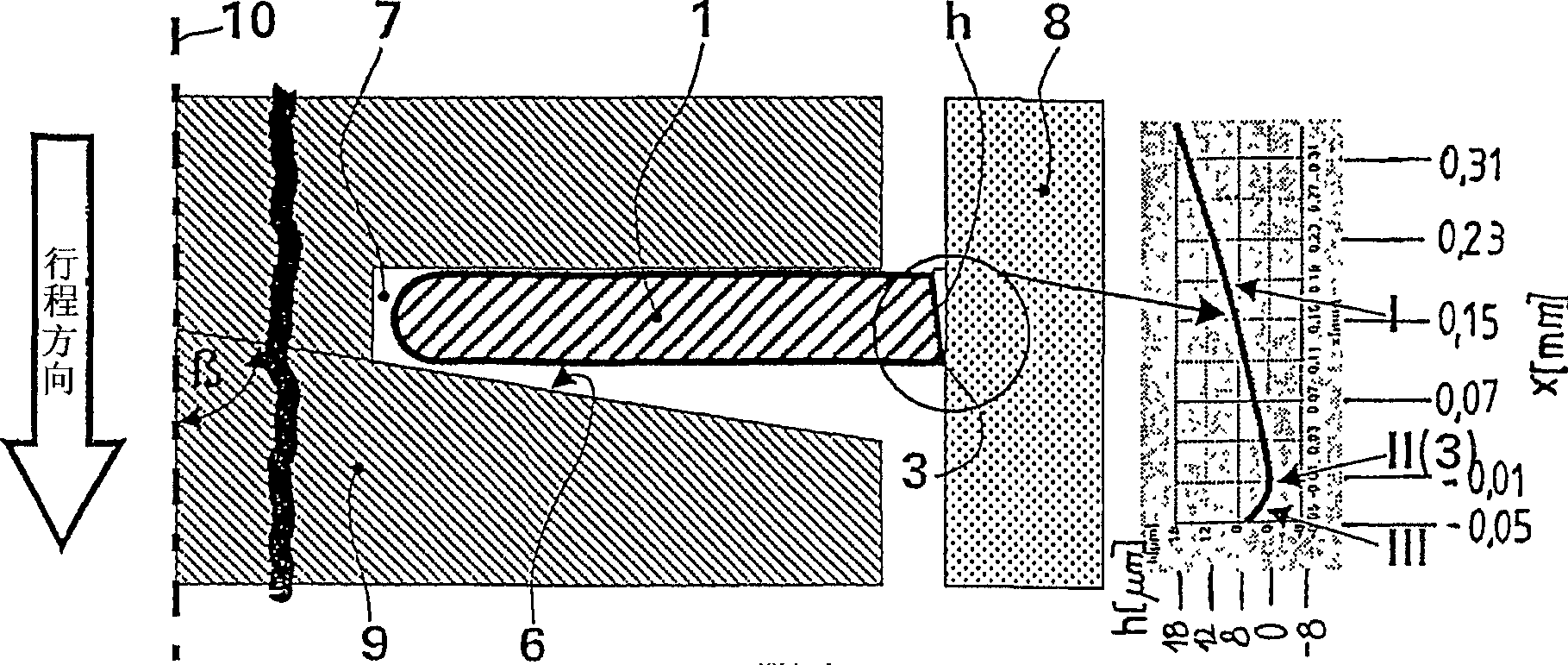

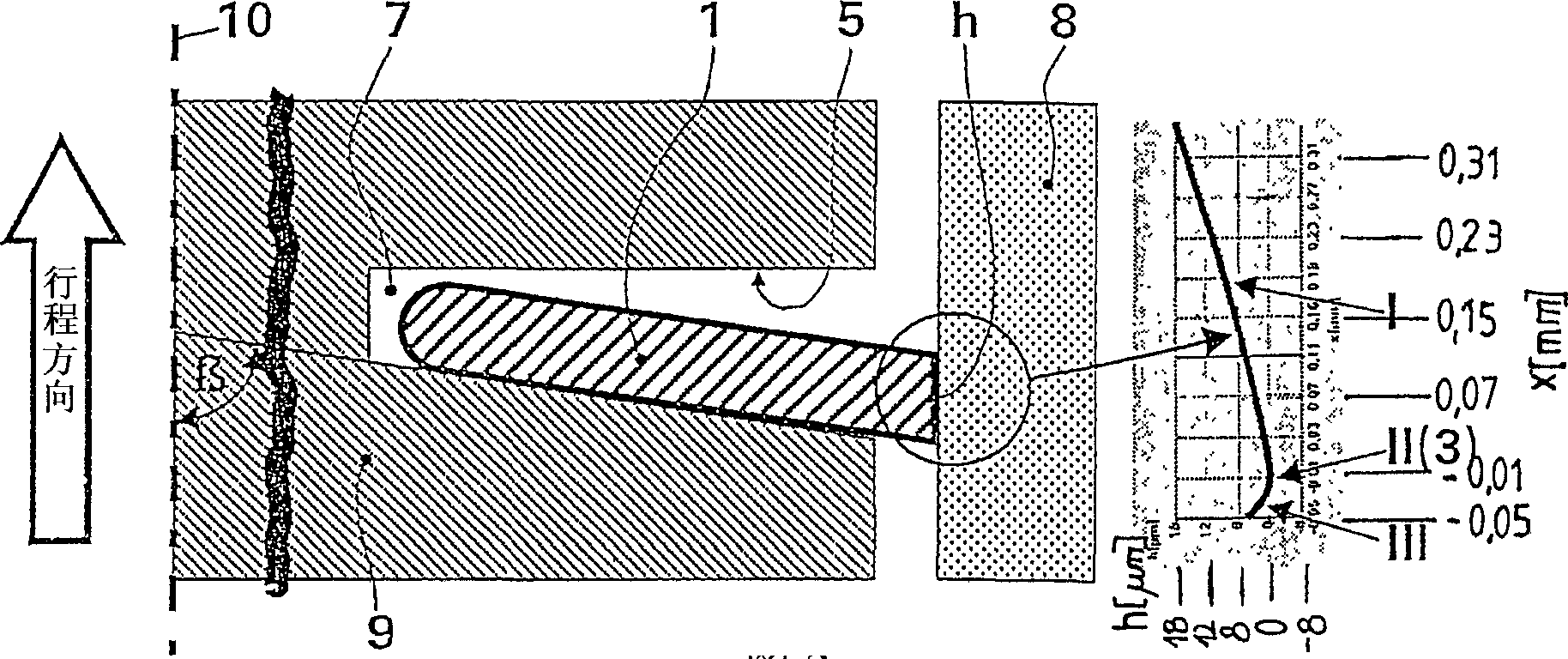

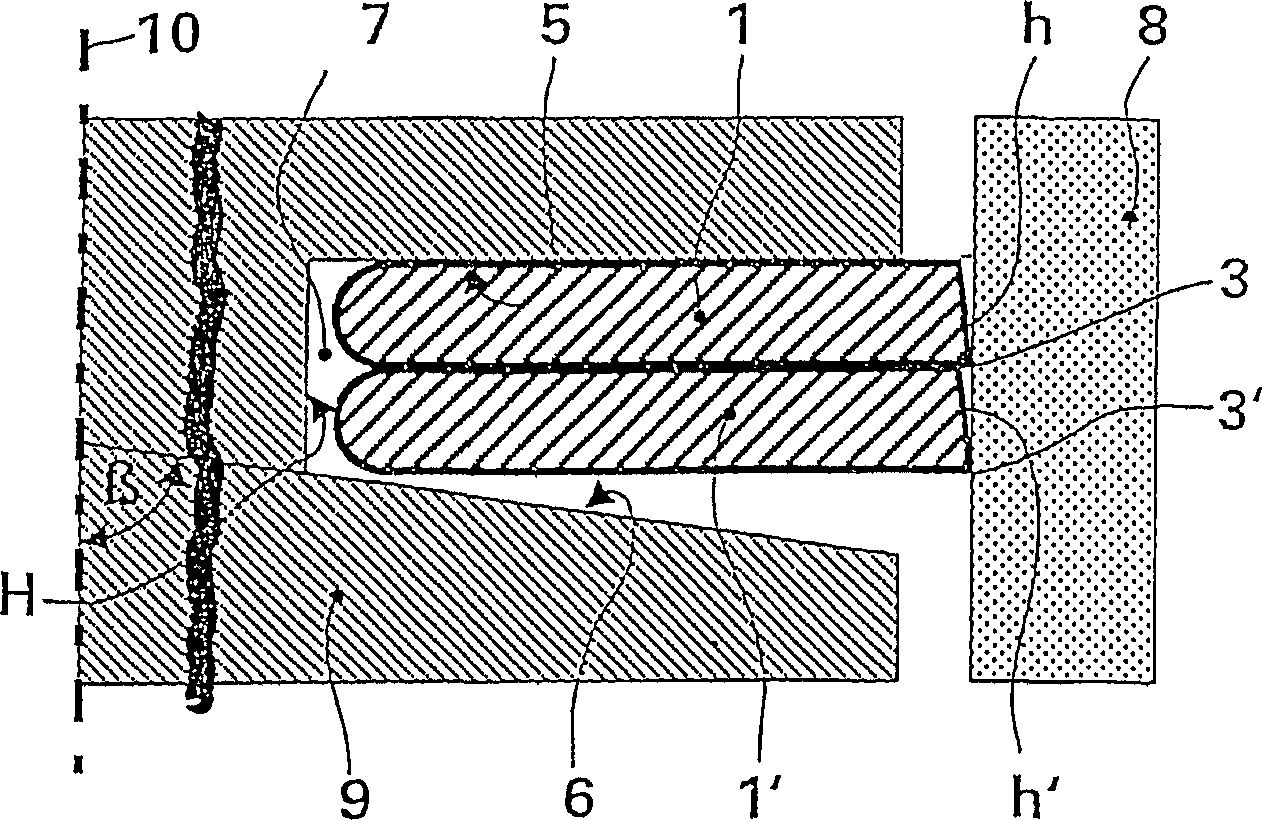

[0032] from figure 1 and figure 2 It can be seen that an oil scraper ring groove arrangement is formed by a disk 1 with a parallel side and a running surface h. The disc 1 is arranged in an annular groove 7 of a piston 9 with its running face h aligned to the cylinder wall 8 of the engine. One ring groove side 5 represents the side of the top side of the piston, and one ring groove side 6 represents the side facing away from the piston top. According to the invention, the ring groove side 5 on the piston top side is aligned at 90° to the piston shaft 10 , wherein the ring groove side 6 facing away from the piston top extends at an angle β in the range of 85° to 87° to the outer diameter of the piston.

[0033] According to the arrangement of the oil wiper ring groove, the disk 1 has a coronal asymmetrically shaped working surface h, which contains a vertex line 3 extending around the periphery of the disk, wherein the vertex line 3 acts as the oil scraper ring and The edge...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap