External color filter and the color LCD panel structure therewith

A color filter and liquid crystal display technology, applied in static indicators, instruments, optics, etc., can solve the problems of affecting the curing effect of the PI layer, increasing process requirements, and increasing production costs, so as to improve the uniformity of box thickness and reduce The effect of material loss and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

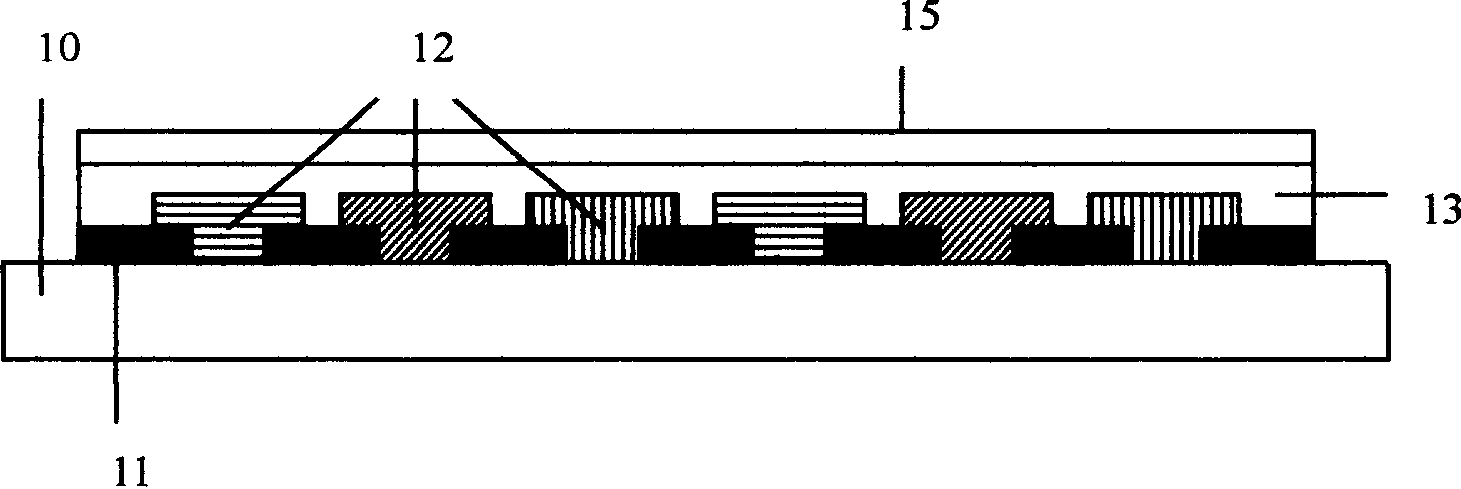

[0026] see image 3 , which is a schematic structural diagram of the external color filter according to the first embodiment of the invention. It includes a substrate 2 made of a transparent polymer flexible material (the substrate can also be made of glass), firstly a black matrix pattern 3 made on the substrate 2, and then step by step to make red 4, green 5, blue 6 Tri-color tinting layer. And an OC layer 7 is made on the colored layer, wherein a protective layer 1 is respectively bonded to the upper surface of the OC layer 7 and the lower surface of the substrate 2 through an adhesive 8 .

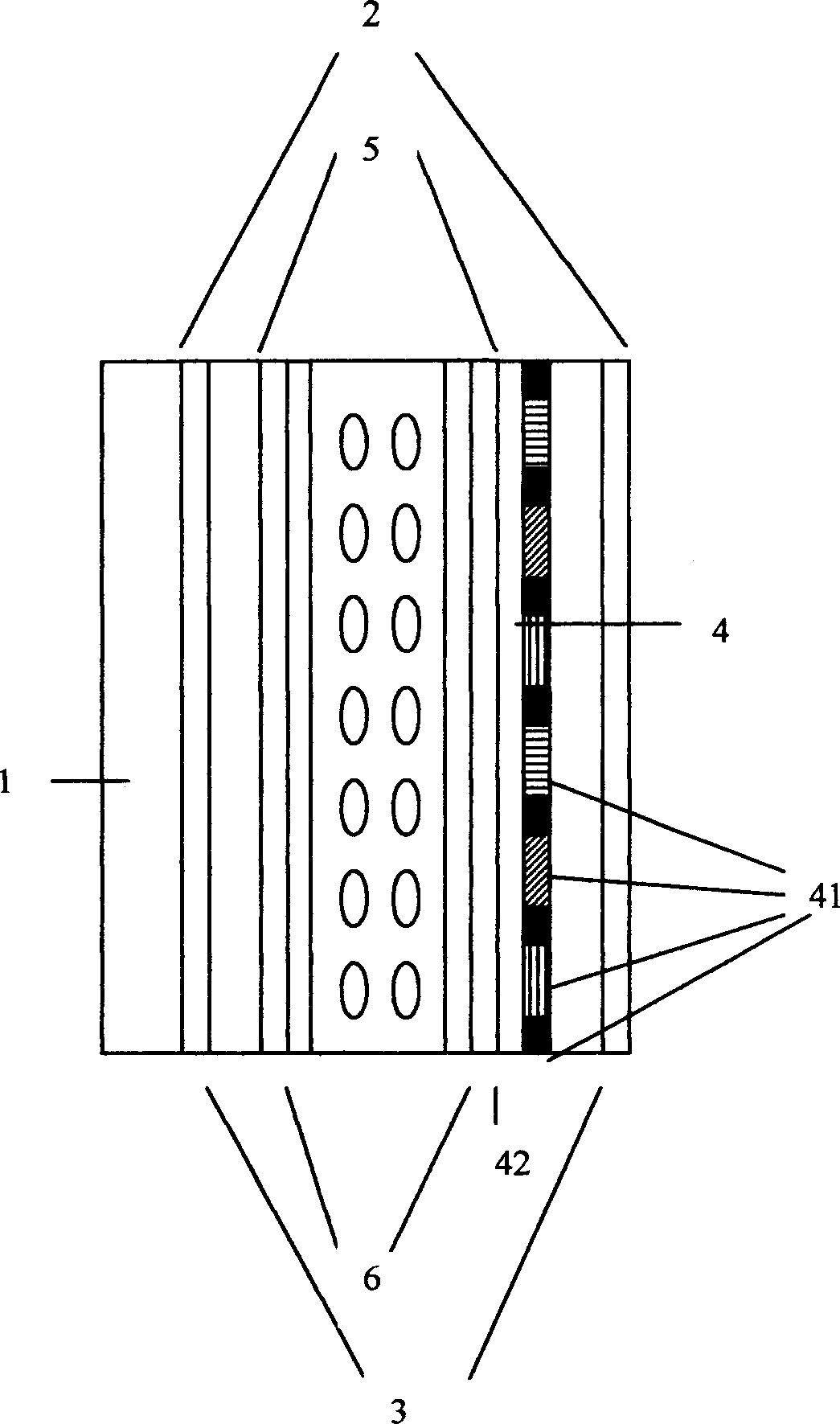

[0027] see Figure 4 , the liquid crystal display panel structure includes upper and lower polarizers 1, upper and lower glass substrates 2, ITO conductive layer 3, PI orientation layer 4, backlight module 5, and the external color filter 6 of the present invention is attached to the backlight module 5. Between the lower polarizer 1 and the lower polarizer 1, the alignment mark 1 as ...

Embodiment 2

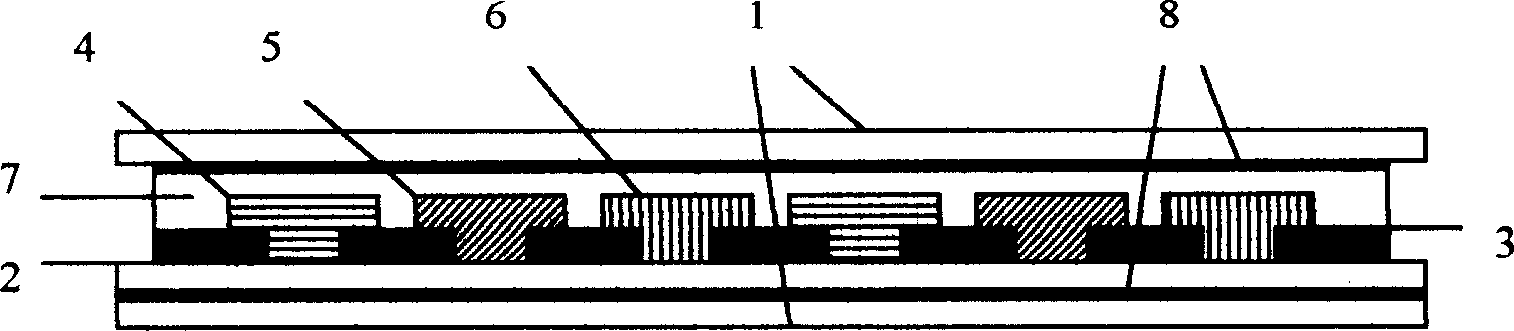

[0029] see Figure 5 , the difference between the external color filter in the second embodiment of the present invention and the external color filter in the first embodiment is that no protective layer is formed on the substrate 2 thereof. In addition, it should be noted that the protective layer outside the substrate and the OC layer can be selectively added, and the protective layer can be added simultaneously outside the substrate and the OC layer, or only on one side, or not on both sides. The protective layer may be a single layer or multiple layers.

[0030] see Image 6 The difference between the LCD panel structure of the second embodiment of the present invention and the LCD panel structure of the first embodiment is that the external color filter 6 is attached between the lower polarizer and the lower glass substrate. In addition, it should be noted that there are multiple options for the position of using the external color filter. In addition to the positions u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com