Substrate, semiconductor device and substrate manufacturing method

A manufacturing method and substrate technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as difficult etching and patterning, achieve convenient testing methods, ensure etching accuracy, and improve crystal growth quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiment of the present application discloses a substrate, including a sapphire substrate and a patterned AlN thin film formed on the sapphire substrate.

[0036] Preferably, the thickness of the AlN thin film is 3-15 μm.

[0037] The application also discloses a semiconductor device, including the substrate and an epitaxial layer formed on the substrate.

[0038] In this technical solution, the semiconductor device is preferably a III-V LED device. In some embodiments, the semiconductor device may also be other AlN-based devices such as surface acoustic wave devices, high-frequency high-power devices, and the like.

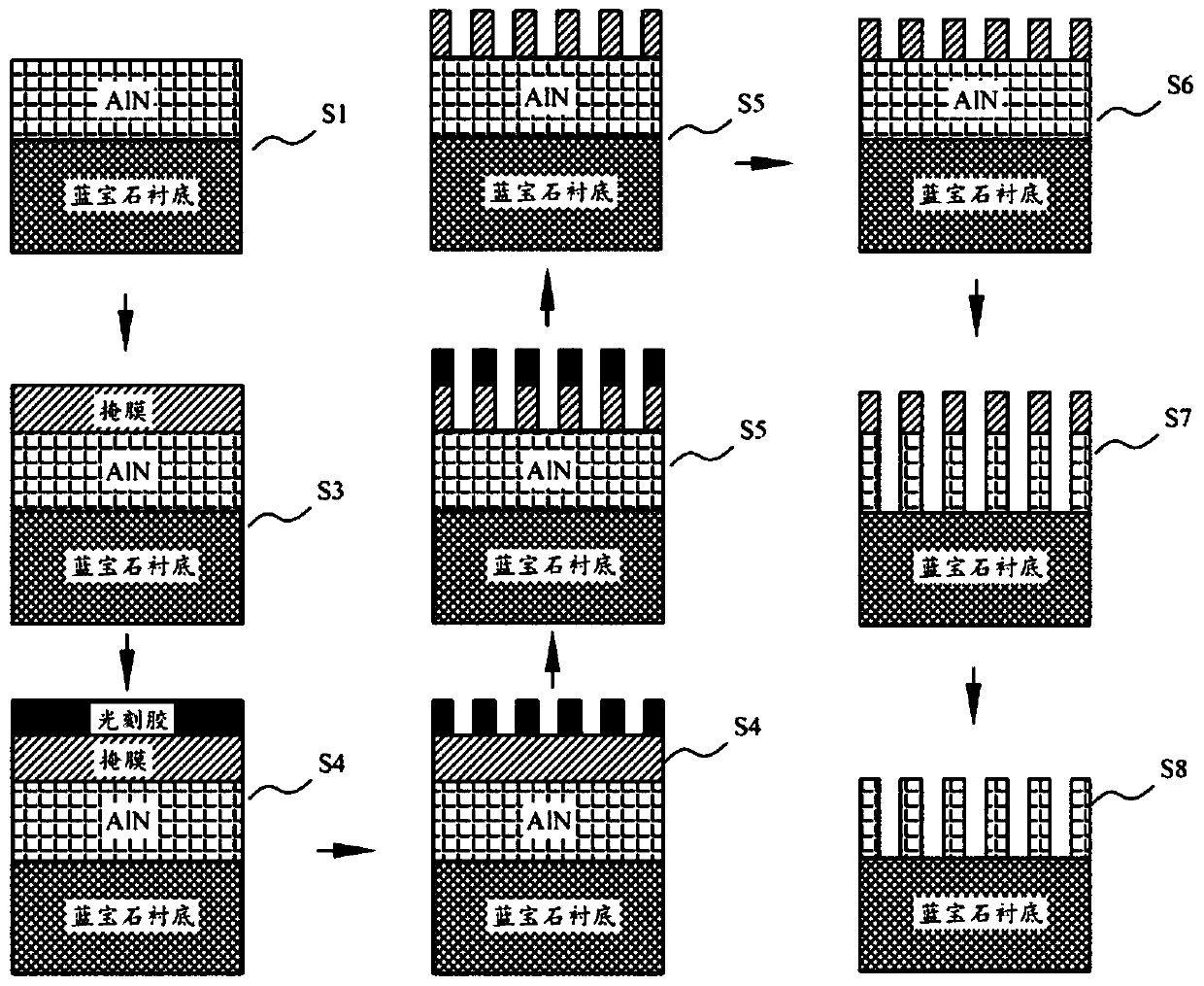

[0039] The present application also discloses a method for manufacturing a substrate. First, the mask material is evaporated, and then the mask is etched by dry method, and AlN is etched by wet method, and finally the mask material is removed, thereby forming a patterned AlN film. method, using this method, a patterned AlN film on an AlN / sapphire t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com