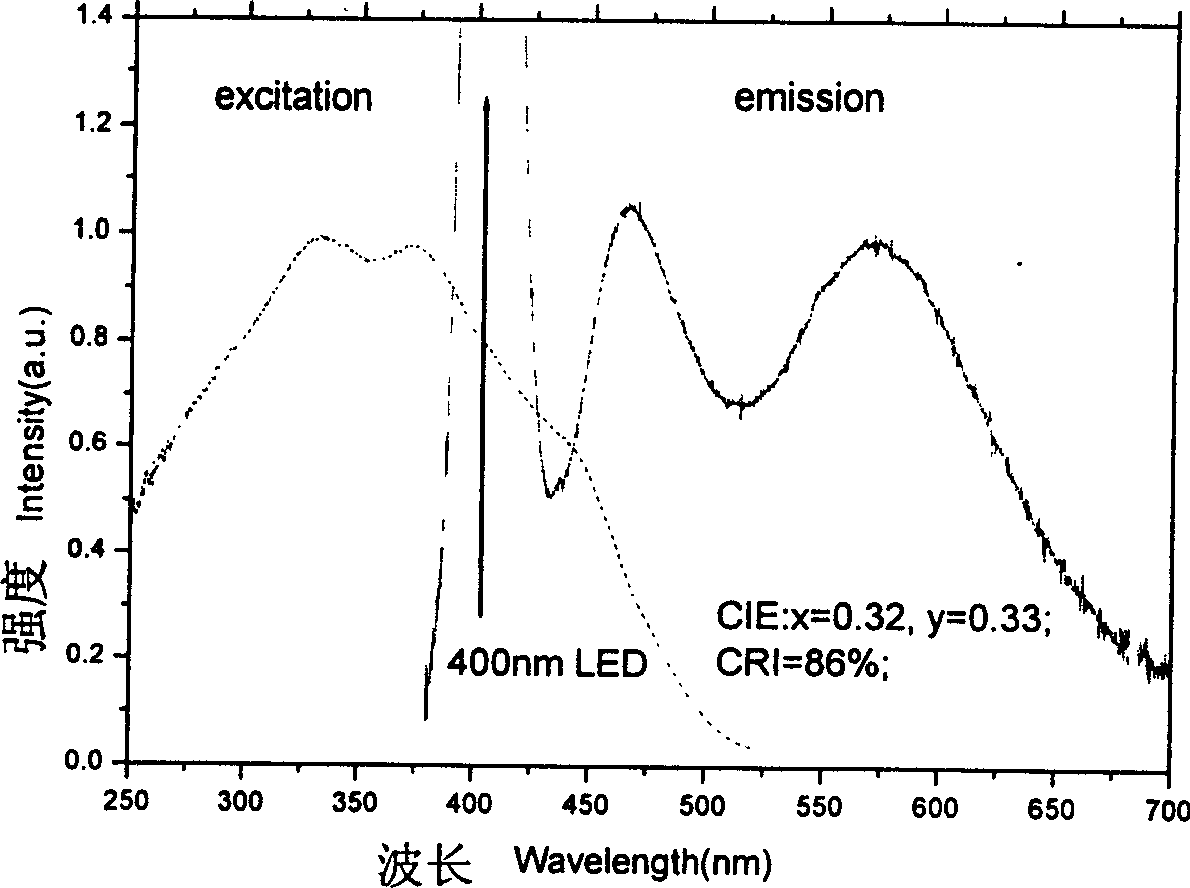

Single-phase whitelight fluorescent powder for ultraviolet light excitation

A technology of ultraviolet light and phosphor powder, applied in the field of light-emitting, can solve the problems of unsatisfactory light-emitting performance and lack of white light phosphor powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: Preparation of Eu xy Sr y-xy MgSi z o 2z+y+1 , where x=0.01; y=2; z=0.5, the specific expression is: Eu 0.02 Sr 1.98 MgSi 0.5 o 4 . Calculate and weigh raw materials according to x=0.01; y=2; z=0.5, weigh 3.52g Eu 2 o 3 , 292.2 g SrCO 3 , 40.3g MgO and 30g SiO 2 , to mix them. After fully grinding and mixing the above raw materials, put them into a high-purity corundum crucible or a platinum crucible, and put them into a high-temperature furnace; heat them for 3-5 hours at a temperature of 1100°C-1400°C under carbon or hydrogen reduction conditions, and then take them out Obtain a single-phase white phosphor: Eu 0.02 Sr 1.98 MgSi 0.5 o 4 .

Embodiment 2

[0011] Embodiment 2: Preparation of Eu xy Sr y-xy MgSi z o 2z+y+1 , where x=0.05, y=2, z=0.5, the specific expression is: Eu 0.1 Sr 2-0.1 MgSi 0.5 o 4 . Calculate and weigh raw materials according to x=0.05, y=2, z=0.5, weigh 17.6g Eu 2 o 3 , 280.44 g SrCO 3 , 40.3g MgO and 30g SiO 2 , to mix them. After fully grinding and mixing the above raw materials, put them into a high-purity corundum crucible or a platinum crucible, and put them into a high-temperature furnace; heat them for 3-5 hours at a temperature of 1100°C-1400°C under carbon or hydrogen reduction conditions, and then take them out Obtain a single-phase white phosphor Eu 0.1 Sr 2-0.1 MgSi 0.5 o 4 .

Embodiment 3

[0012] Embodiment 3: Preparation of Eu xy Sr y-xy MgSi z o 2z+y+1 , where x=0.01, y=2.8, z=0.5, the specific expression is: Eu 0.028 Sr 2.8-0.028 MgSi 0.5 o 4.8 . Calculate and weigh raw materials according to x=0.01, y=2.8, z=0.5, weigh 4.928g Eu 2 o 3 , 409.15 g SrCO 3 , 40.3g MgO and 30g SiO 2 , to mix them. After fully grinding and mixing the above raw materials, put them into a high-purity corundum crucible or a platinum crucible, and put them into a high-temperature furnace; heat them for 3-5 hours at a temperature of 1100°C-1400°C under carbon or hydrogen reduction conditions, and then take them out Obtain a single-phase white phosphor Eu 0.028 Sr 2.8-0.028 MgSi 0.5 o 4.8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com