Manufacture of wood imitated products

A manufacturing method and technology for wood products, applied in decorative arts, special decorative structures, etc., can solve the problems of unstable shape of resin molded products, reduce overall appearance and touch, and achieve overall shape and dimensional stability, easy maintenance, The effect of strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

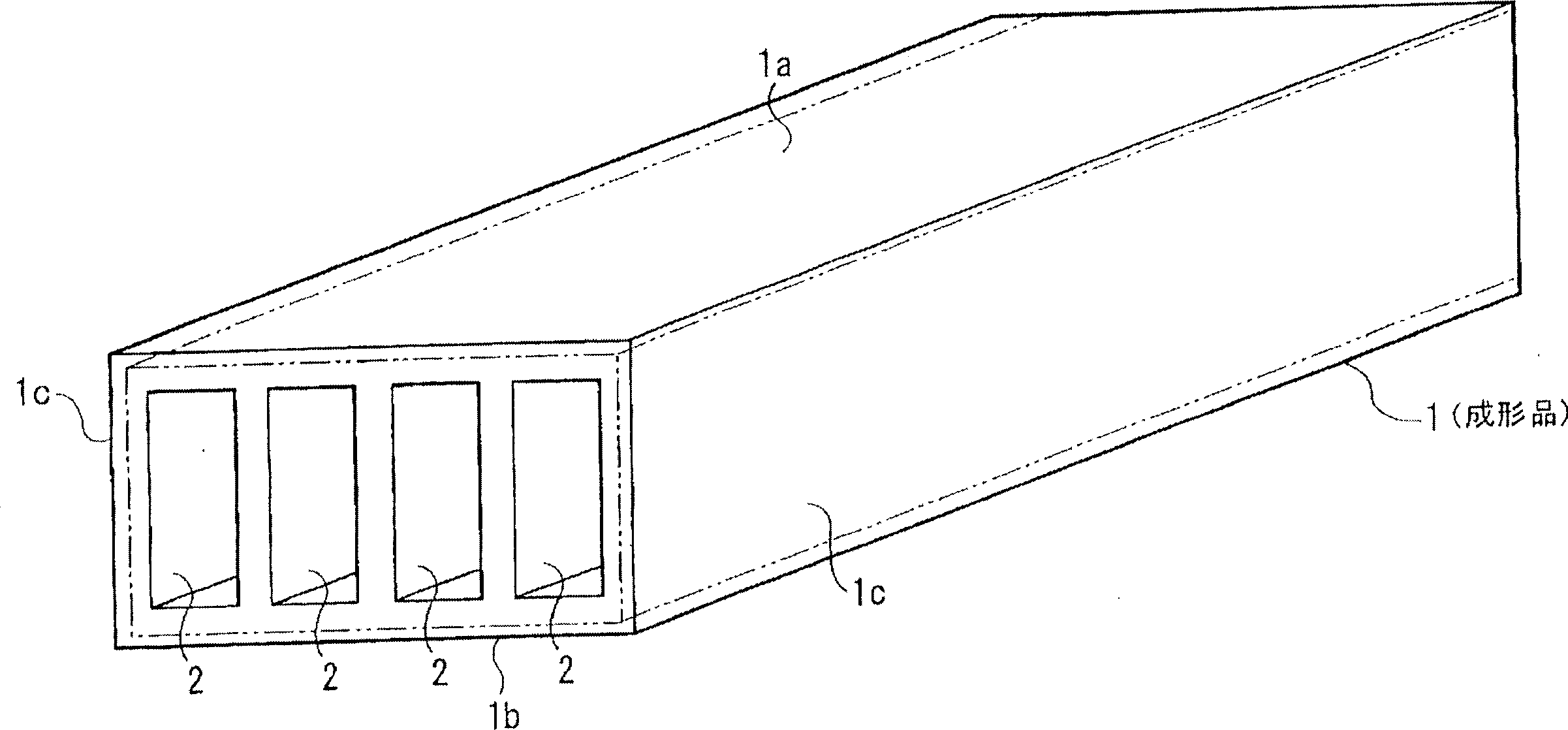

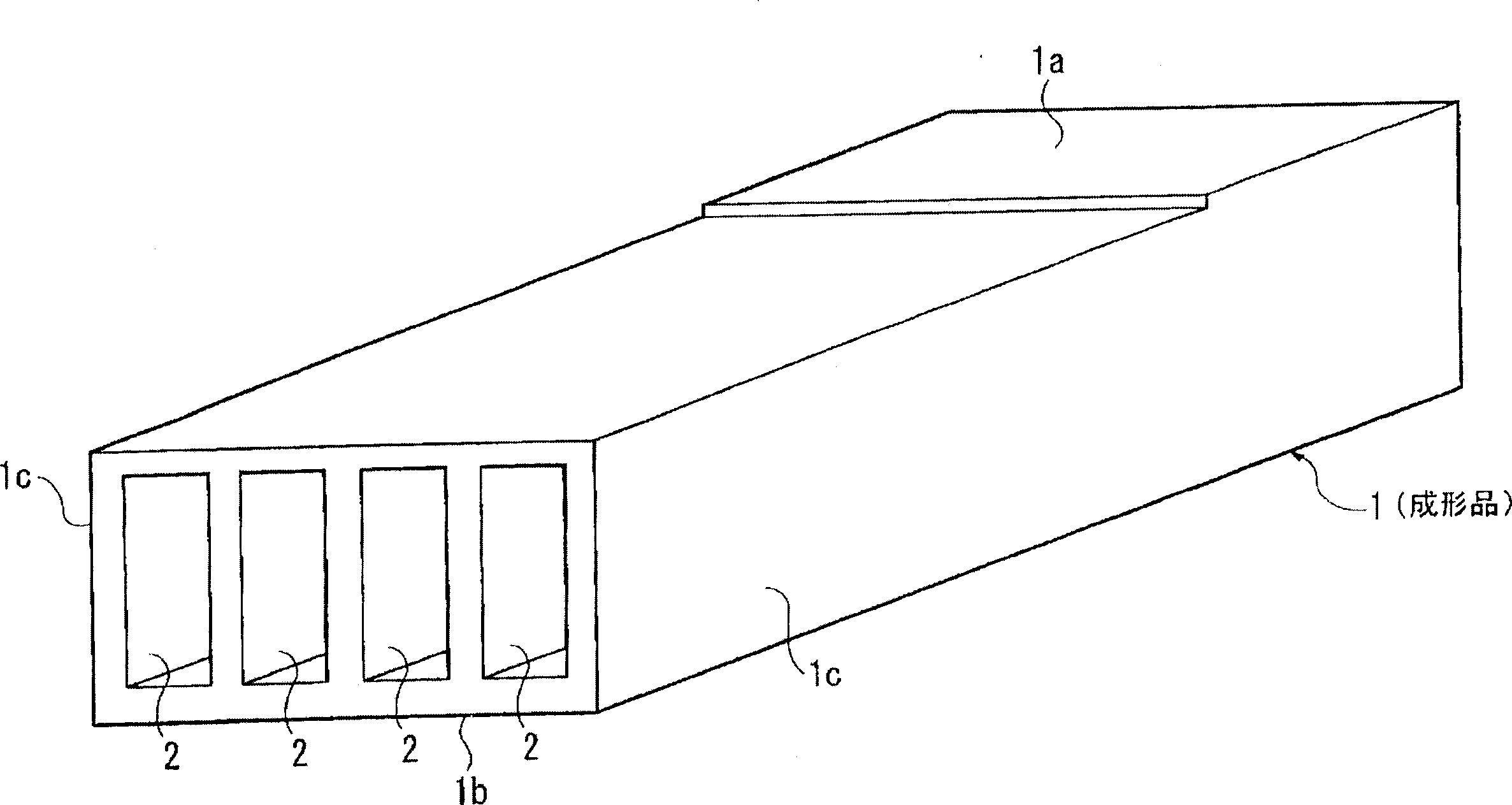

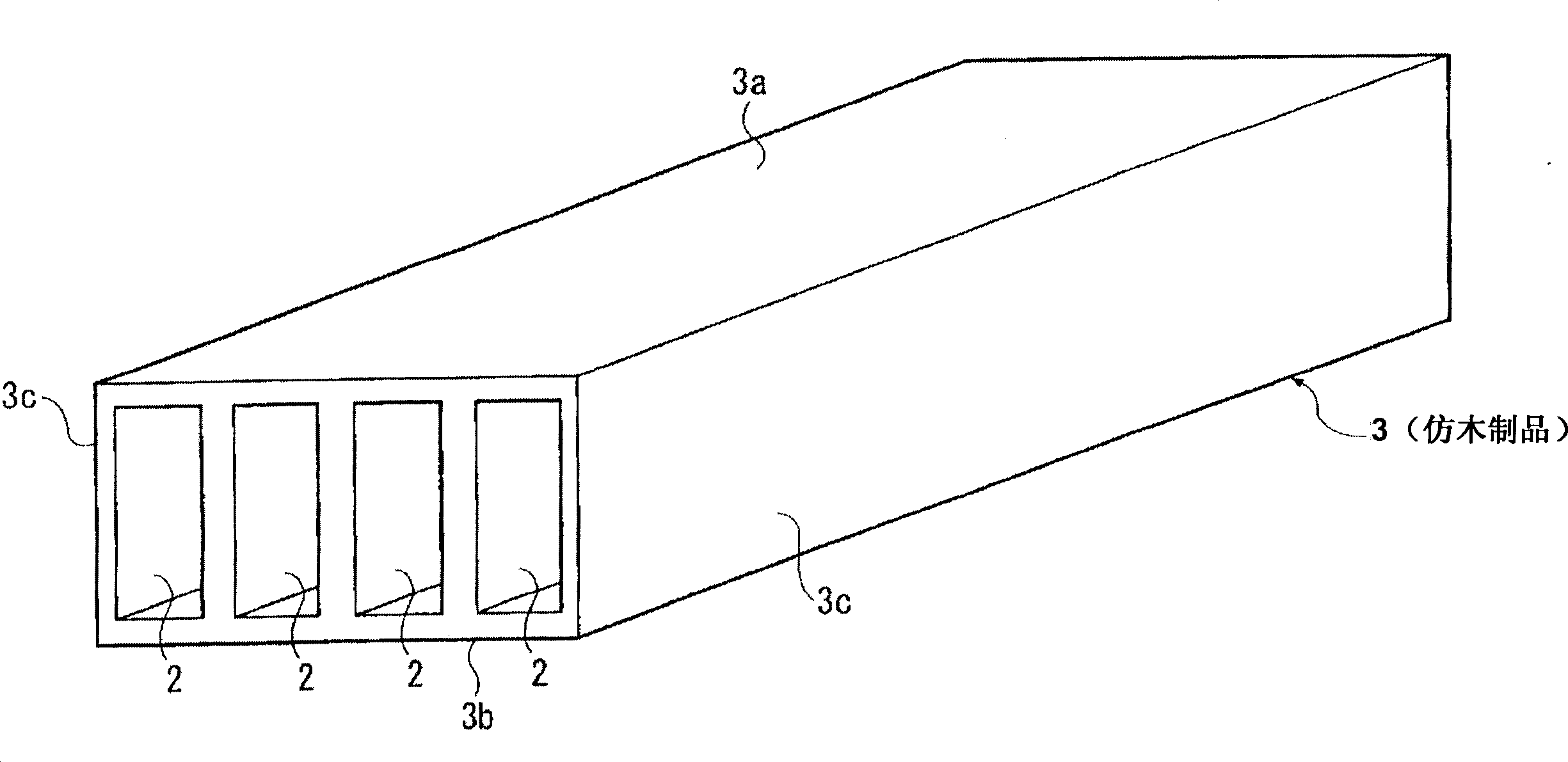

[0040] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Figure 1 to Figure 3 It is a schematic diagram showing the processes in the manufacturing method of imitation wood products applicable to the present invention in stages. figure 1 It is a perspective view showing the molded product used when manufacturing the imitation wood product of the present invention; figure 2 is said to be figure 1 A three-dimensional view of a part of the surface of the molded product shown when only the specified thickness is shaved off; image 3 Indicates that the same thickness is applied to the entire surface of the molded product figure 2 The imitation wood product of this embodiment is completed through the process shown and through the implementation of grinding processing and coating processing. in addition, Figure 4 with Figure 5 is expressed in Figure 1 to Figure 3 Among the molded products in , a cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com