Coal planer and method for controlling same

A technology of coal plowing and ground control, which is applied in general control systems, damping devices, control/regulation systems, etc., and can solve problems such as chain wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

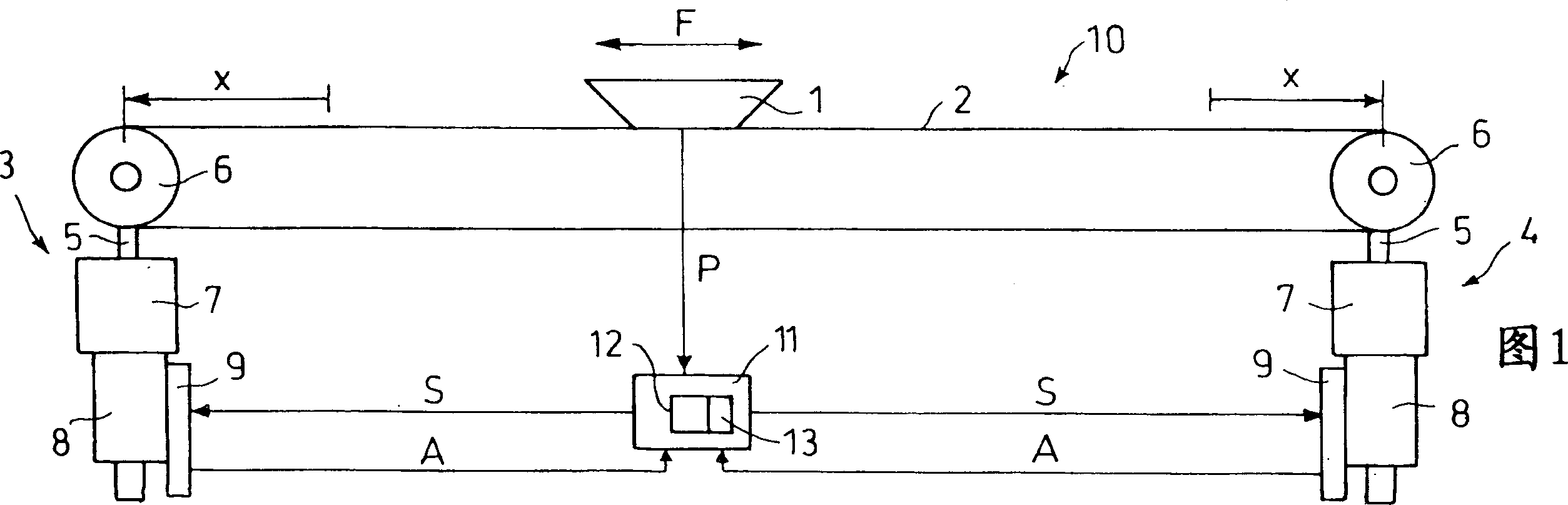

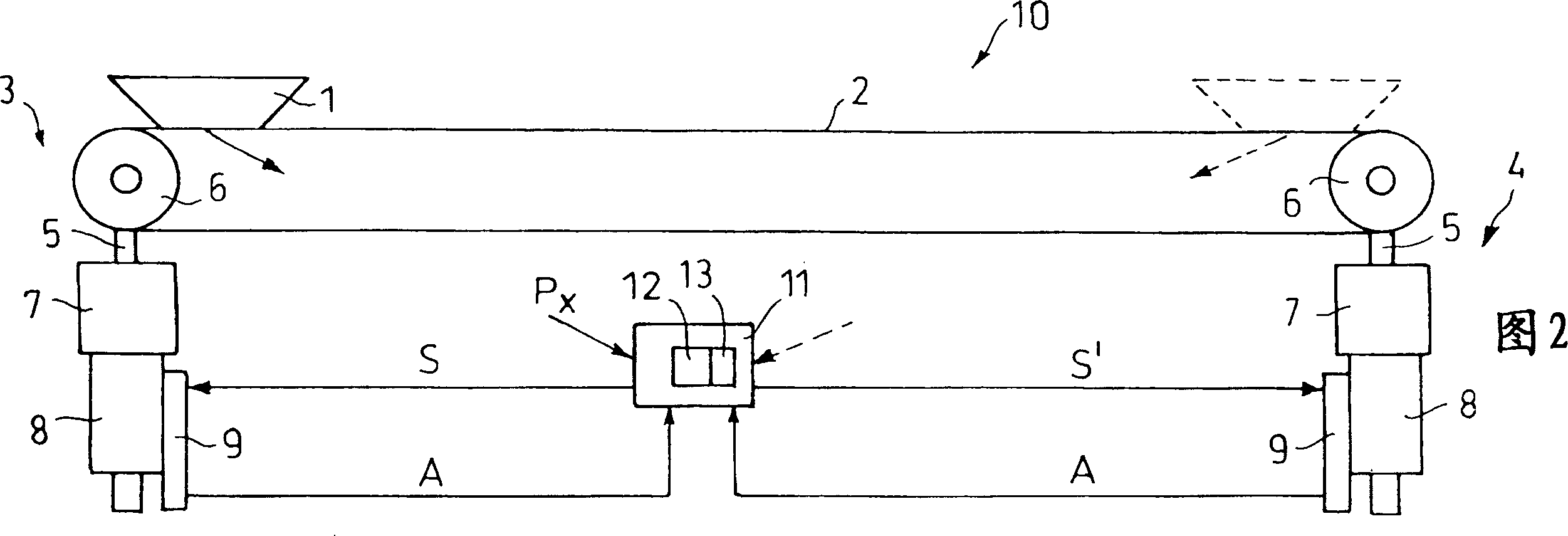

[0015] In the drawings, a plowing device according to the invention is generally indicated with the reference number 10, which has a plowing blade 1, which is connected between end-mounted chain drives 3 and 4 for the plowing chain 2 by means of a plowing chain. forward and reverse reciprocating motion. The forward and reverse movement of planer 1 is indicated by double arrow F in FIG. 1 . The two chain drives 3, 4 are designed identically in principle and comprise a sprocket 6 supported on the drive shaft 5, a transmission box 7 and a drive motor 8, which in the shown embodiment is a belt drive respectively. There is, for example, an inverter motor with an inverter control circuit provided in a separate switch box 9 . During continuous operation, the frequency converter motor 8 can be operated variable in speed at a speed within a comparatively large bandwidth, for example 80 to 1800 l / min, wherein the speed of rotation of the drive sprocket 6 and the operating speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com