Drive control apparatus for magnetic stepping motor and sewing machine

A stepping motor and driven technology, which is applied in the direction of program-controlled sewing machines, motor generator control, control systems, etc., can solve the problem of not being able to reliably prevent pattern deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

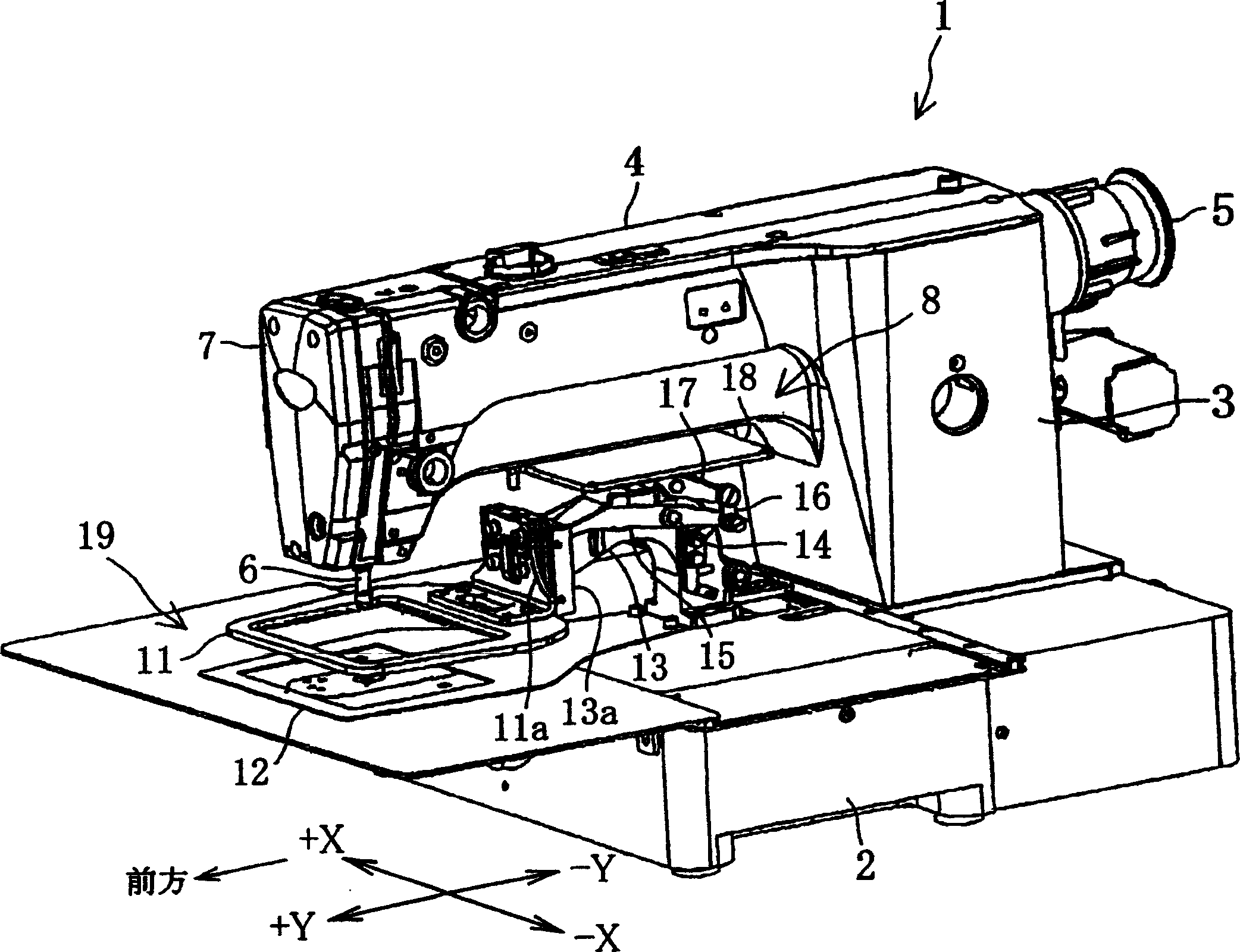

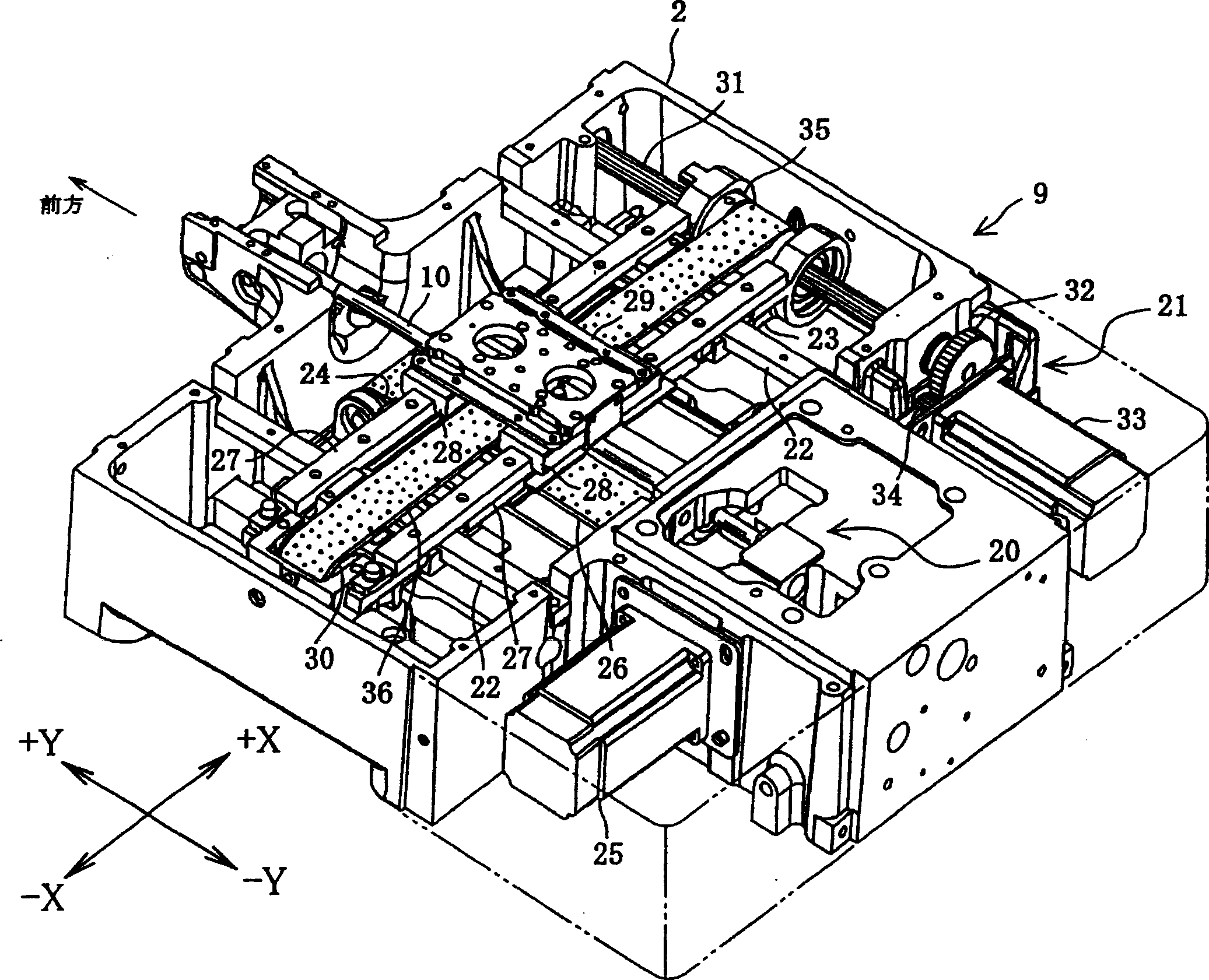

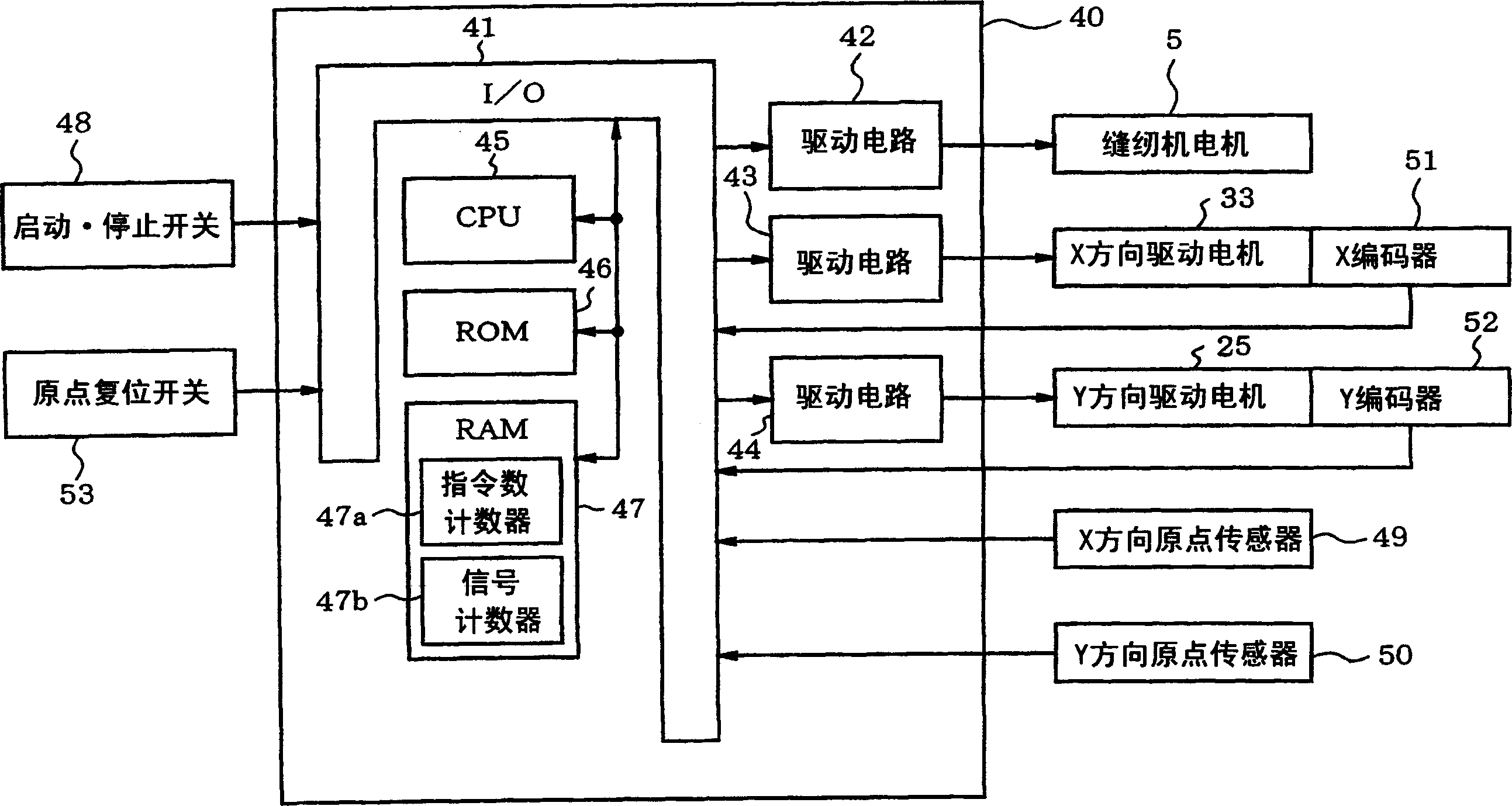

[0020] In order to explain this invention in detail, it demonstrates referring drawings. Figure 1 to Figure 5 An example in which the present invention is applied to a fancy knotting sewing machine is shown.

[0021] Such as figure 1 As shown, the fancy knotting sewing machine 1 has: a base part 2, a column part 3 erected from the rear end part of the base part 2, and a front side facing the base part 2 from the upper end part of the column part 3. Extended arm section 4.

[0022] A sewing machine motor 5 and a driving force transmission mechanism (not shown) for transmitting the driving force of the sewing machine motor 5 to the needle bar 6 via the main shaft are provided in the column portion 3 and the machine arm portion 4 . A needle bar up and down movement mechanism (not shown) for moving the needle bar 6 up and down is provided at the front end of the machine arm part 4 , that is, inside the machine head 7 . By driving the sewing machine motor 5, the sewing needle m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com