Permanent-magnet synchronous motor and compressor using this

A technology of permanent magnets and synchronous motors, applied in synchronous machines, synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, etc., can solve the problems of characteristic deterioration, waveform distortion, etc., and achieve Effect of Reducing Waveform Distortion Rate

Inactive Publication Date: 2010-11-10

HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the case of the latter, there are many cases where the waveform distortion is also increased, and the characteristics are deteriorated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

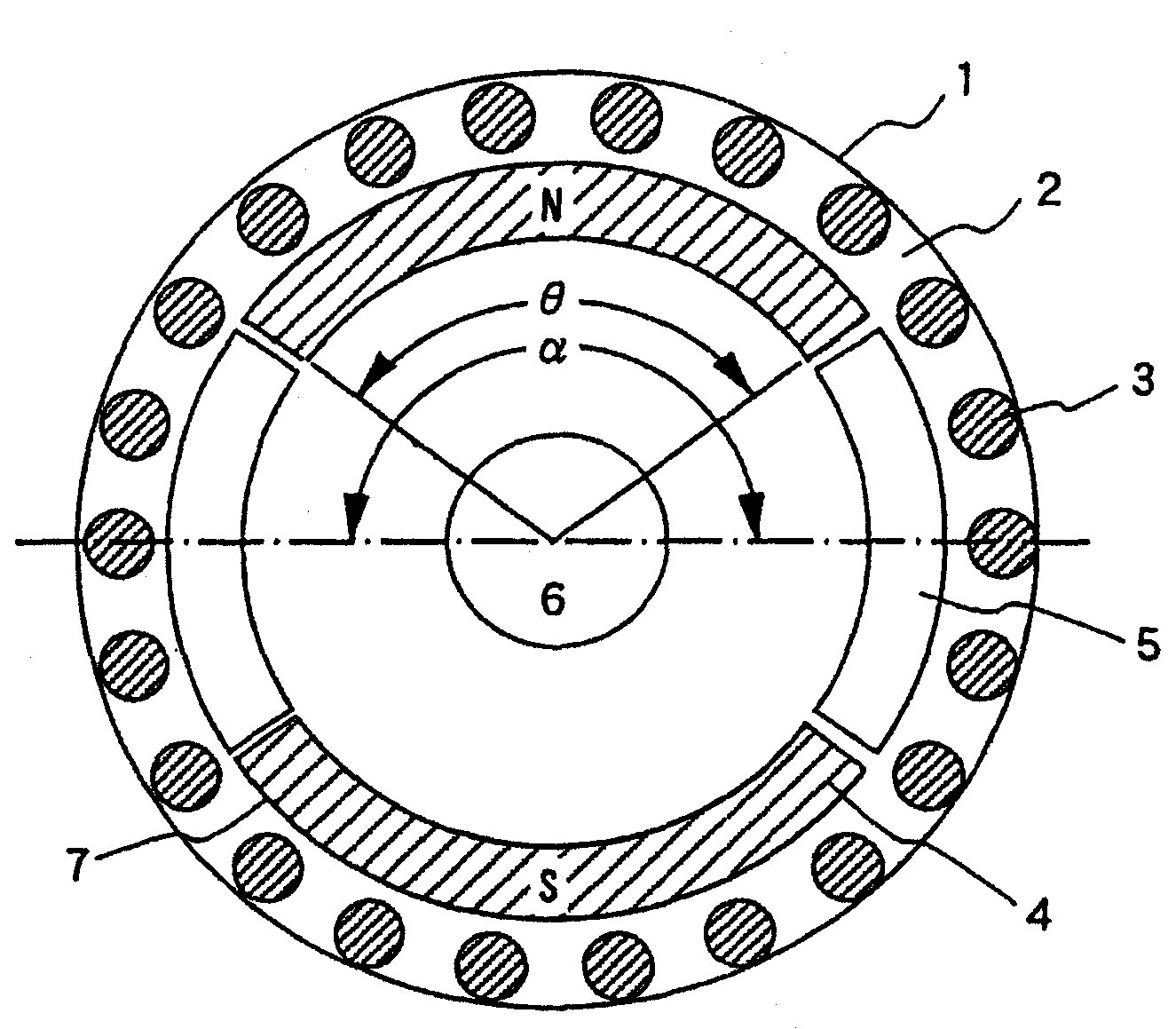

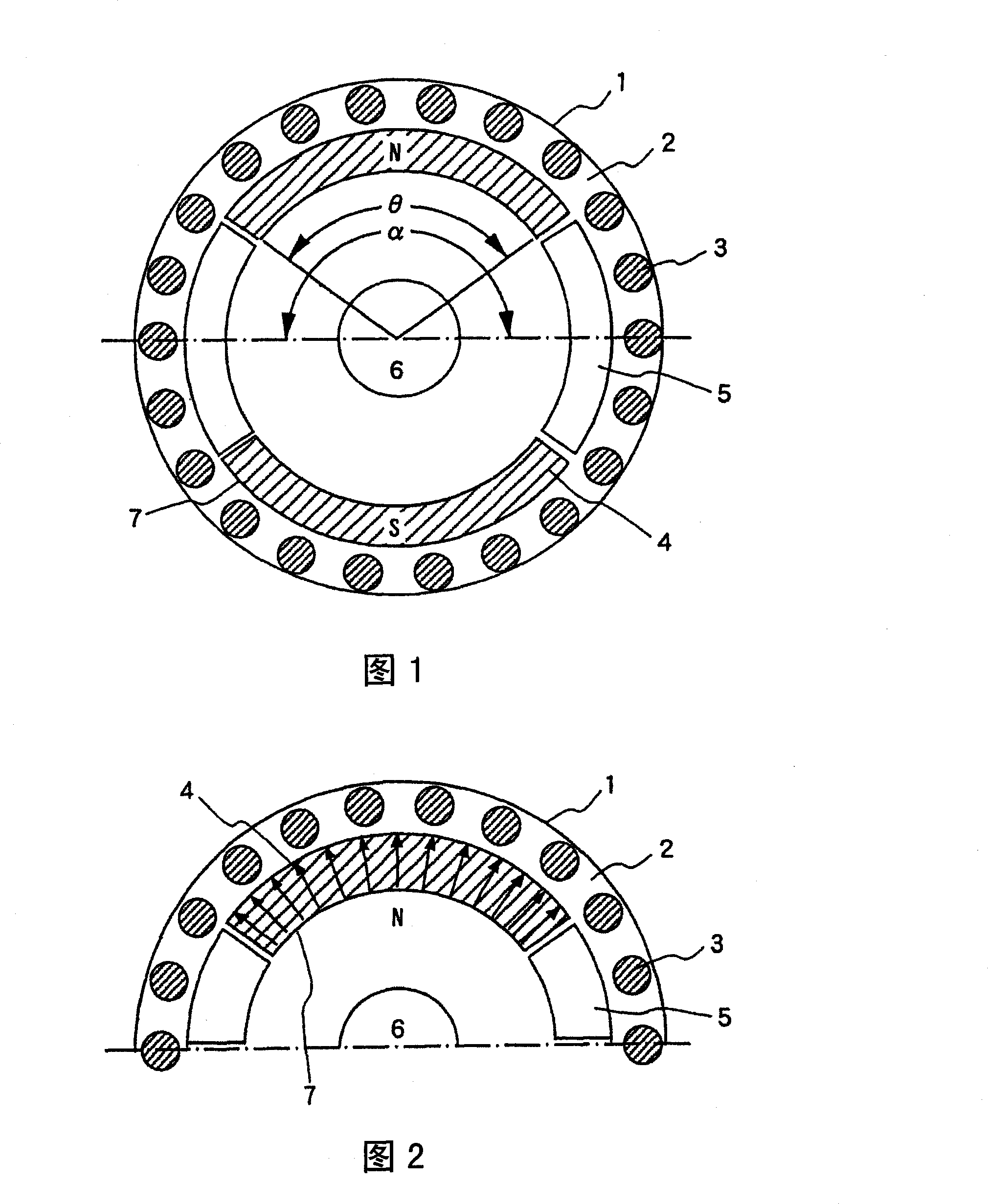

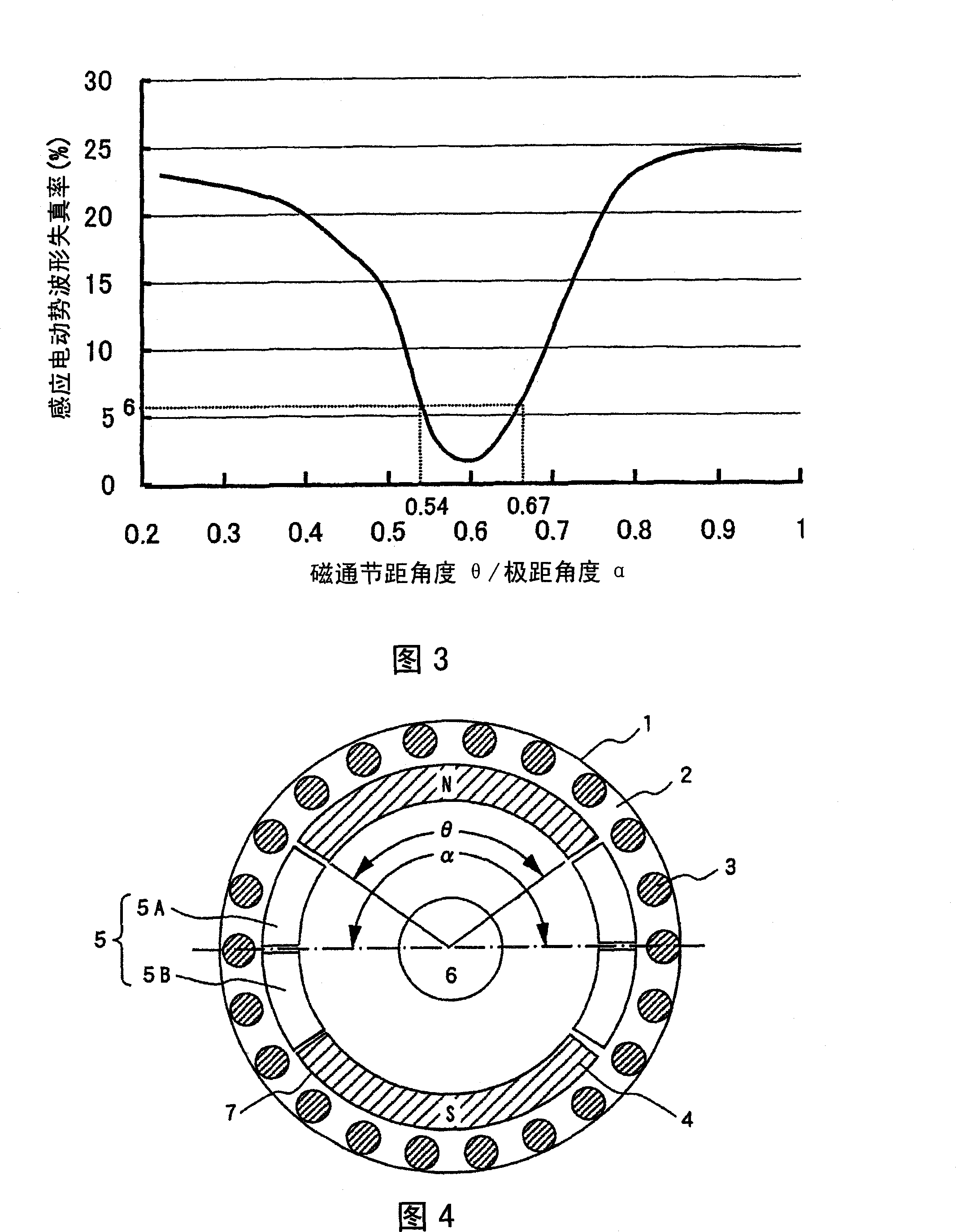

A permanent-magnet synchronous motor provided with a rotor structure having cage-type windings and a permanent magnet disposed on the inner peripheral side of the cage-type winding bar, wherein the permanent magnet is magnetized to provide a ratio theta / alpha of 0.54 through 0.67 between the peripheral-direction pitch angle theta of the permanent magnet's magnetic flux distribution and a magneticpole pitch angle alpha so as to ensure a required induced electromotive force with no increase in iron loss and to reduce a waveform distortion rate. Accordingly, a high-efficiency permanent-magnet synchronous motor can be provided due to an induced electromotive force having little distortion and a shape of nearly a sinusoidal wave.

Description

Permanent magnet synchronous motor and compressor using it technical field The invention relates to a permanent magnet synchronous motor and a compressor using it. Background technique The advantage of the induction motor is that it not only has a solid structure, but also can be started by directly turning on a commercial power supply, and can be configured at low cost as a driving source for a constant-speed drive that does not require speed control. On the other hand, like an induction motor, a synchronous motor not only has a low-cost configuration of the drive unit, but also has the advantage that it greatly contributes to the high efficiency of the drive system because there is almost no secondary copper loss during normal operation. However, as a disadvantage, there is a cage winding for starting on the outer peripheral side of the rotor, and it is necessary to further arrange permanent magnets on the inner peripheral side of the cage conductor, which limits the sp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02K3/18H02K1/22H02K21/46H02K1/27H02K21/16

CPCH02K1/223H02K21/46

Inventor 菊地聪小原木春雄吉川富夫中山进野泽重和泽孝一郎渡边刚

Owner HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com