Method for using ash produced in cigarette production in tobacco reproduction (papermaking process)

A technology of reconstituted tobacco leaf and papermaking method, which is applied in the field of tobacco waste recycling, can solve the problems affecting the paper machine's copying, loss, and small soot particles, and achieve the effects of improving market competitiveness, reducing resource waste, and improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

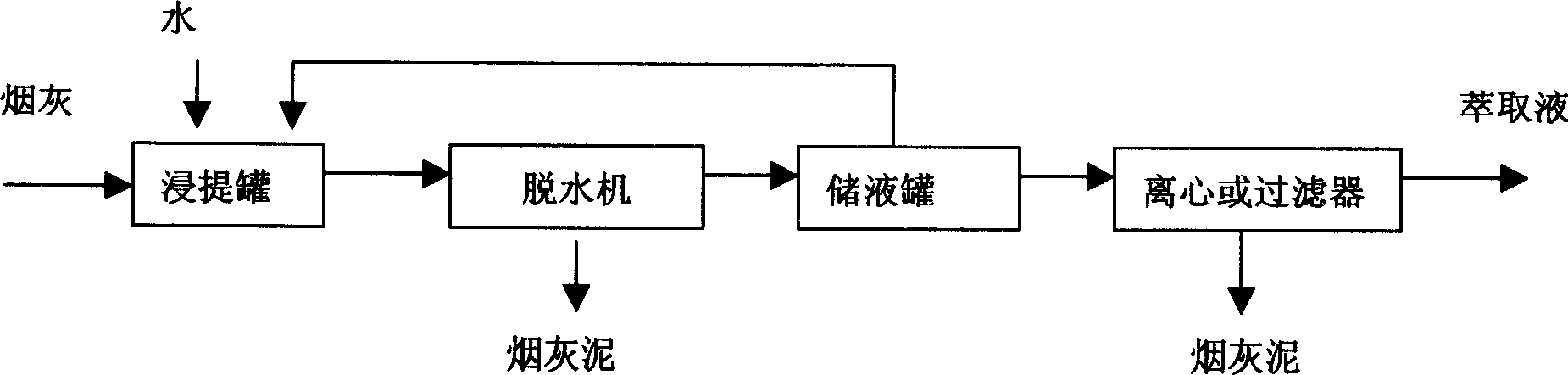

[0016] Add 1 part of soot to 10 parts of water, stir and extract at 65°C for 40 minutes, dehydrate to 30% dryness through a filter press, discard the soot mud, and the extract enters the liquid storage tank, and then pumps it to the extraction tank for the second The second material is 1 part of soot, and it is also stirred and extracted at 65°C for 40 minutes, dehydrated to 30% dryness through a filter press, the extract is put into a liquid storage tank, and then centrifuged to remove the precipitate. The extraction liquid is needed, and the average relative extraction rate of the two parts of soot is 76%, which is added to the extract liquid of tobacco stems and chips at a ratio of 20%, and enters the production process of reconstituted tobacco leaves by the papermaking method.

Embodiment 2

[0018] Add 1 part of soot to 8 parts of water, stir and extract at 80°C for 60 minutes, dehydrate to 35% dryness through a filter press, discard the soot mud, and the extract enters the liquid storage tank, and then pumps it to the extraction tank for the second part Material extraction, the second material is 1 part of soot, also at 80 ° C, stirred and extracted for 60 minutes, dehydrated to 35% dryness through a filter press, the extract was put into a liquid storage tank, and then centrifuged to remove the sediment to obtain the required For the extract, the average relative extraction yield of the two parts of soot is 62%, which is added to the extract of tobacco stems and chips at a ratio of 10%, and enters the production process of reconstituted tobacco leaves by the papermaking method.

Embodiment 3

[0020] Add 1 part of soot to 5 parts of water, stir and extract at 50°C for 30 minutes, dehydrate to 25% dryness through a filter press, discard the soot mud, put the extract into the liquid storage tank, and then centrifuge to remove the sediment to obtain the desired The extract has a relative extraction rate of 60%, which is added to the extract of tobacco stems and chips at a ratio of 20%, and enters the production process of reconstituted tobacco leaves by the papermaking method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com