Simulation technology based on after repair and repair time product effectiveness

A technology of maintenance time and post-event maintenance, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as randomness, unacceptability, and explosion of simulation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

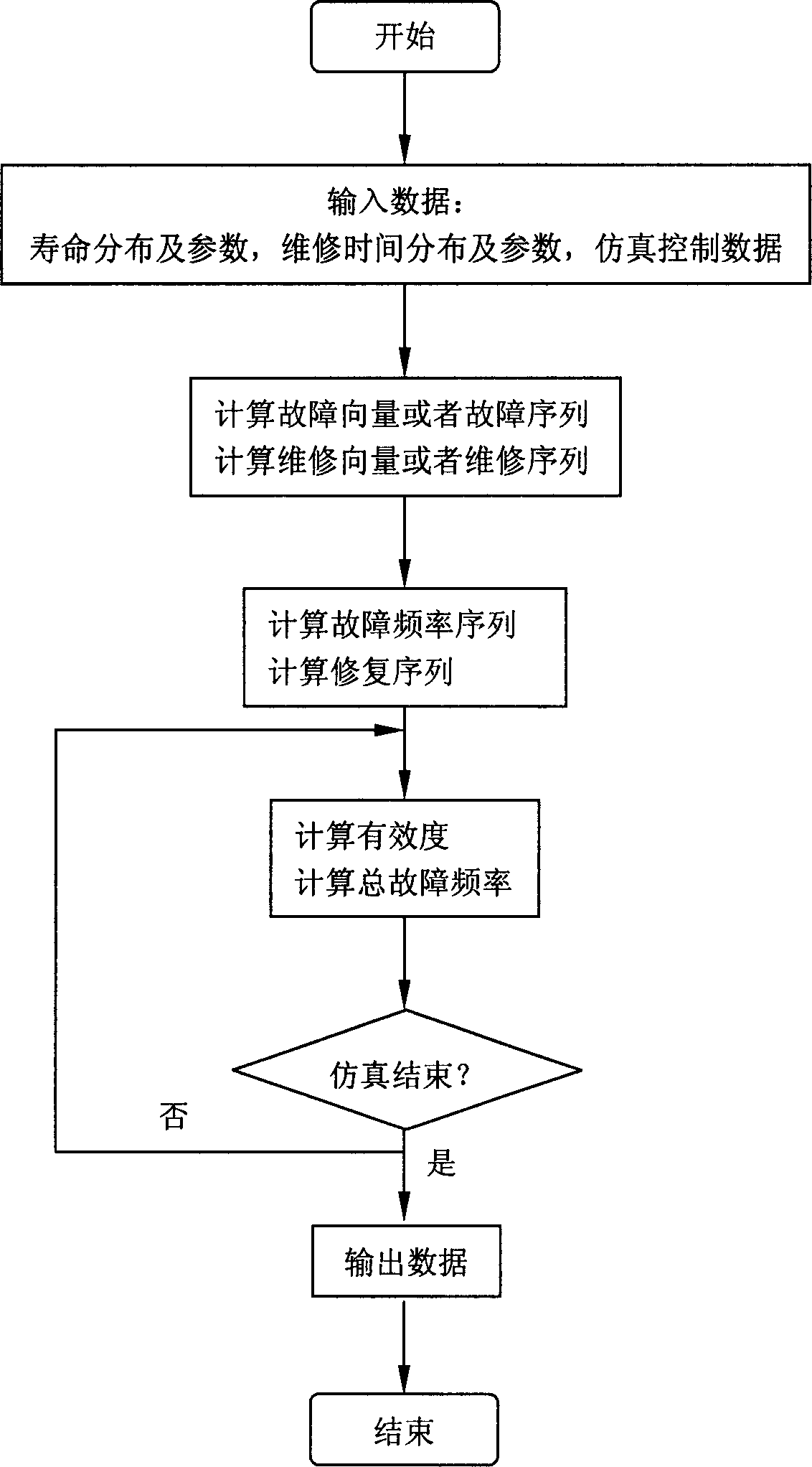

Method used

Image

Examples

Embodiment 1

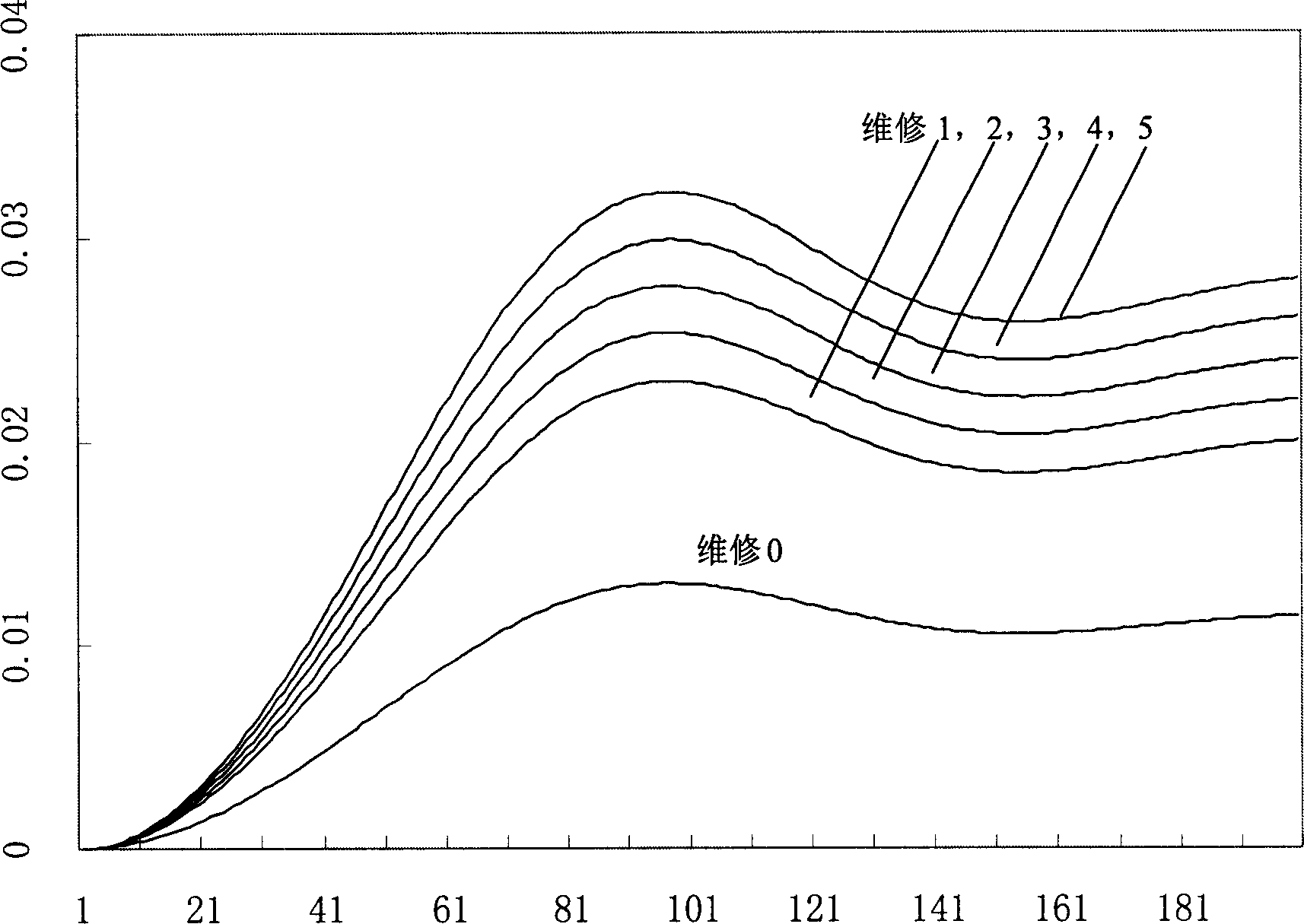

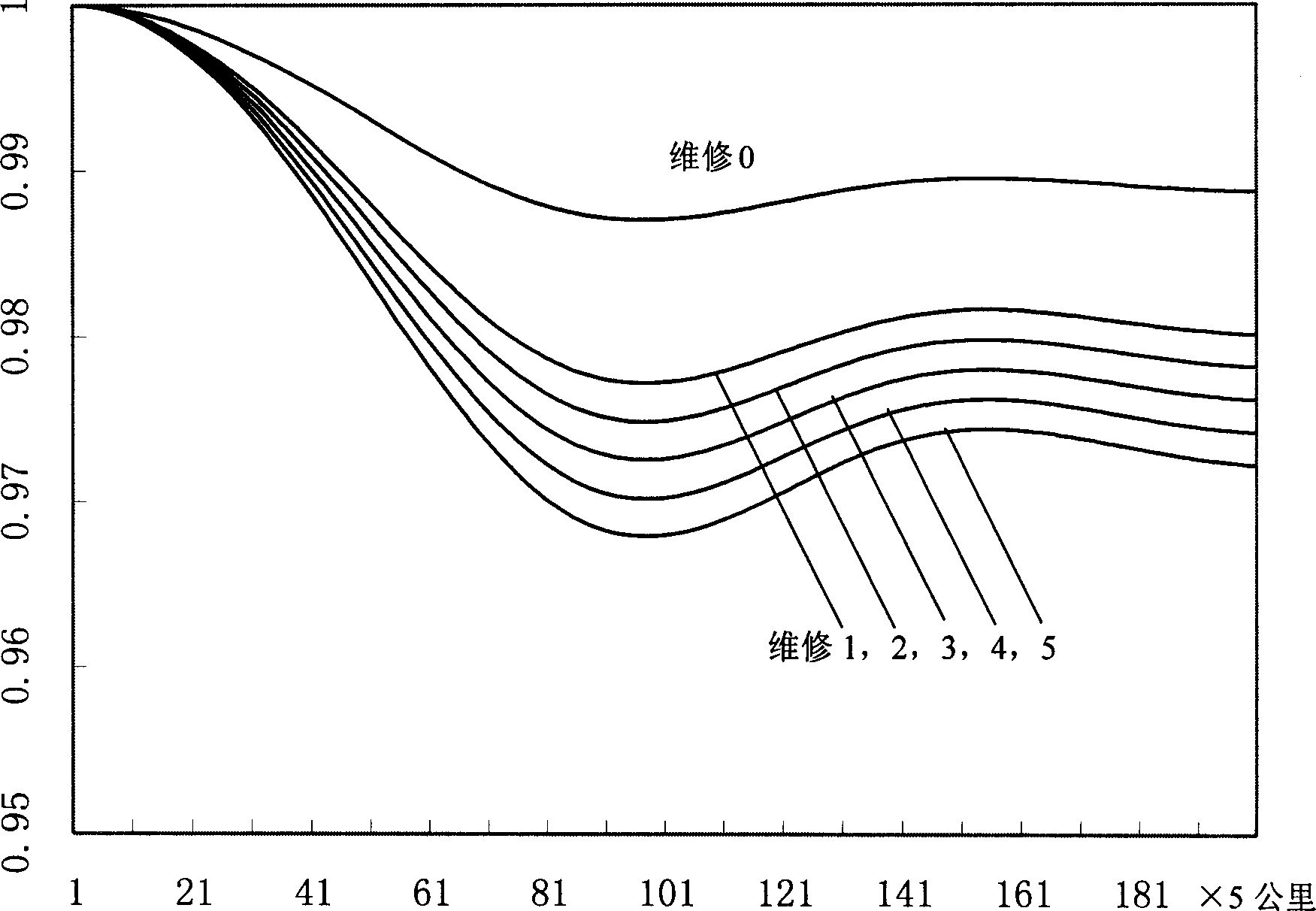

[0102] Taking the tractor chassis as an example to simulate the effectiveness of the tractor chassis under different maintenance time distributions. According to the data, the reliability index of the tractor chassis is known: the average kilometers between failures is MTBF ≥ 450km. The tractor chassis is maintained after the event, and the influence of different maintenance time distributions on the effectiveness of the tractor chassis can be simulated by the simulation method of the present invention. The simulation results can guide the operation and maintenance of the tractor chassis and provide a theoretical basis for the decision-making of the support plan, which is of great significance to ensure the effectiveness or attendance of the tractor.

[0103] The life of the tractor chassis can be fitted by the Weibull distribution function to simulate the effectiveness of the worst case reliability of the tractor chassis, that is, MTBF=450km. The life distribution parameters...

Embodiment 2

[0107] Taking an automobile ignition system as an example to simulate the effectiveness of the automobile ignition system under different maintenance time distributions. According to the data, the reliability index of the automobile ignition system is known: the mean time between failures is MTBF≥200h [1] . The automobile ignition system adopts after-event maintenance, and the effect of different maintenance time distributions on the effectiveness of the automobile ignition system can be simulated by the simulation method of the present invention.

[0108] The life of the automobile ignition system can be fitted with a Weibull distribution function to simulate the effectiveness of the worst reliability of the automobile ignition system, that is, MTBF=200h. The life distribution parameters of the automobile ignition system are shown in Table 5. Different maintenance time distributions are used to observe the effect of maintenance time on the effectiveness of the vehicle ignit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com