Printing web cleaner

A technology for cleaning devices and web materials, which is applied in the field of processing systems and can solve problems such as multi-energy, consumption, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

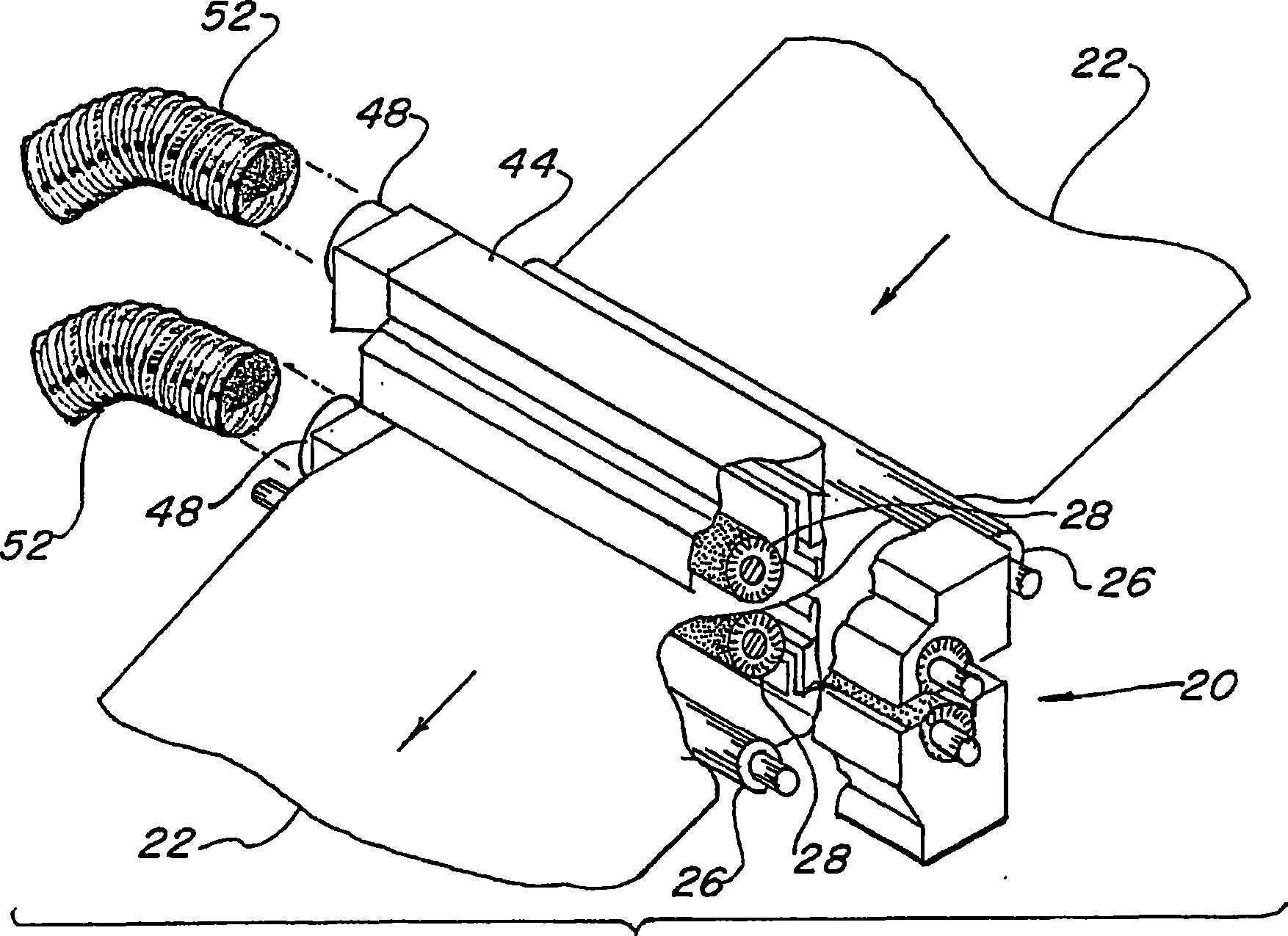

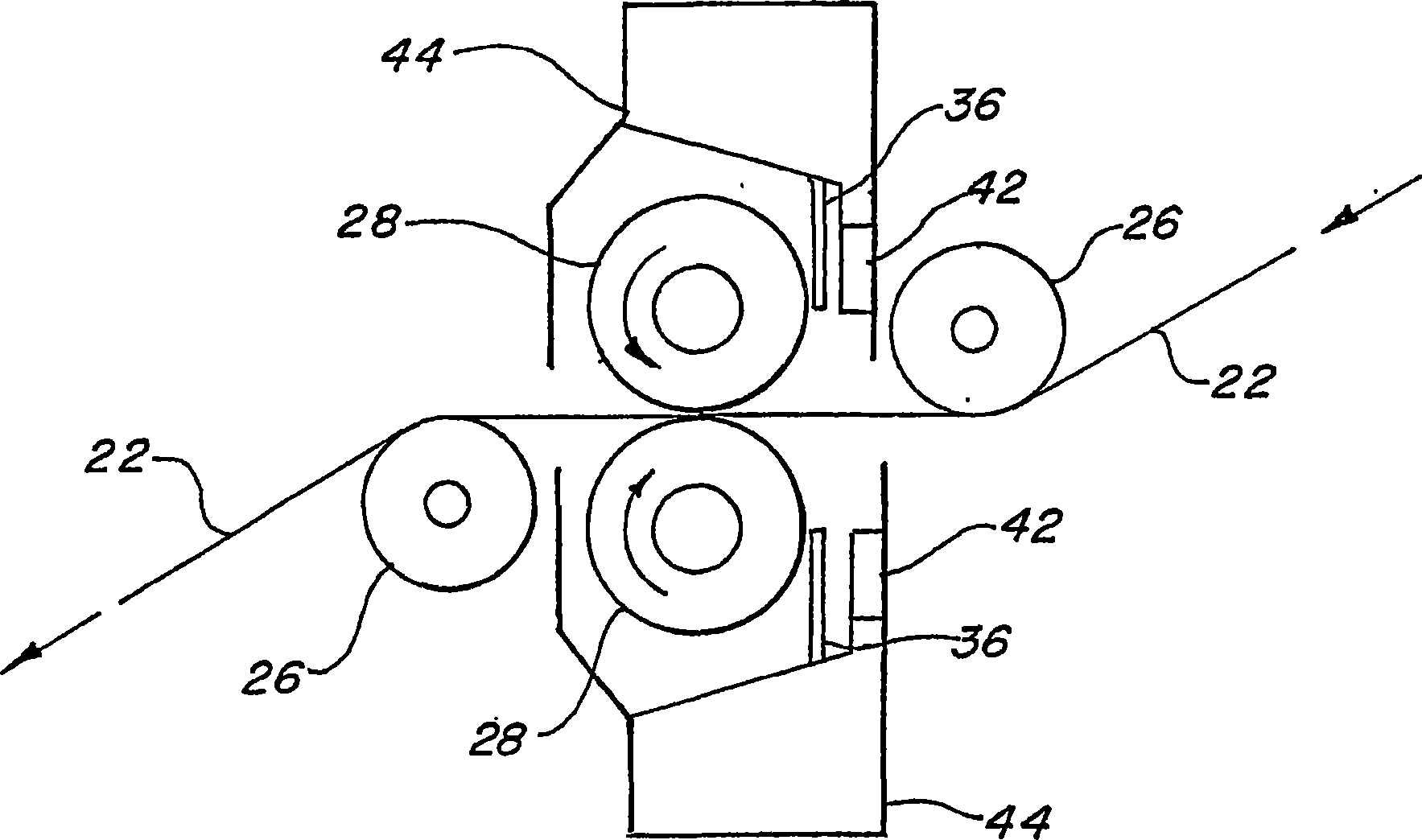

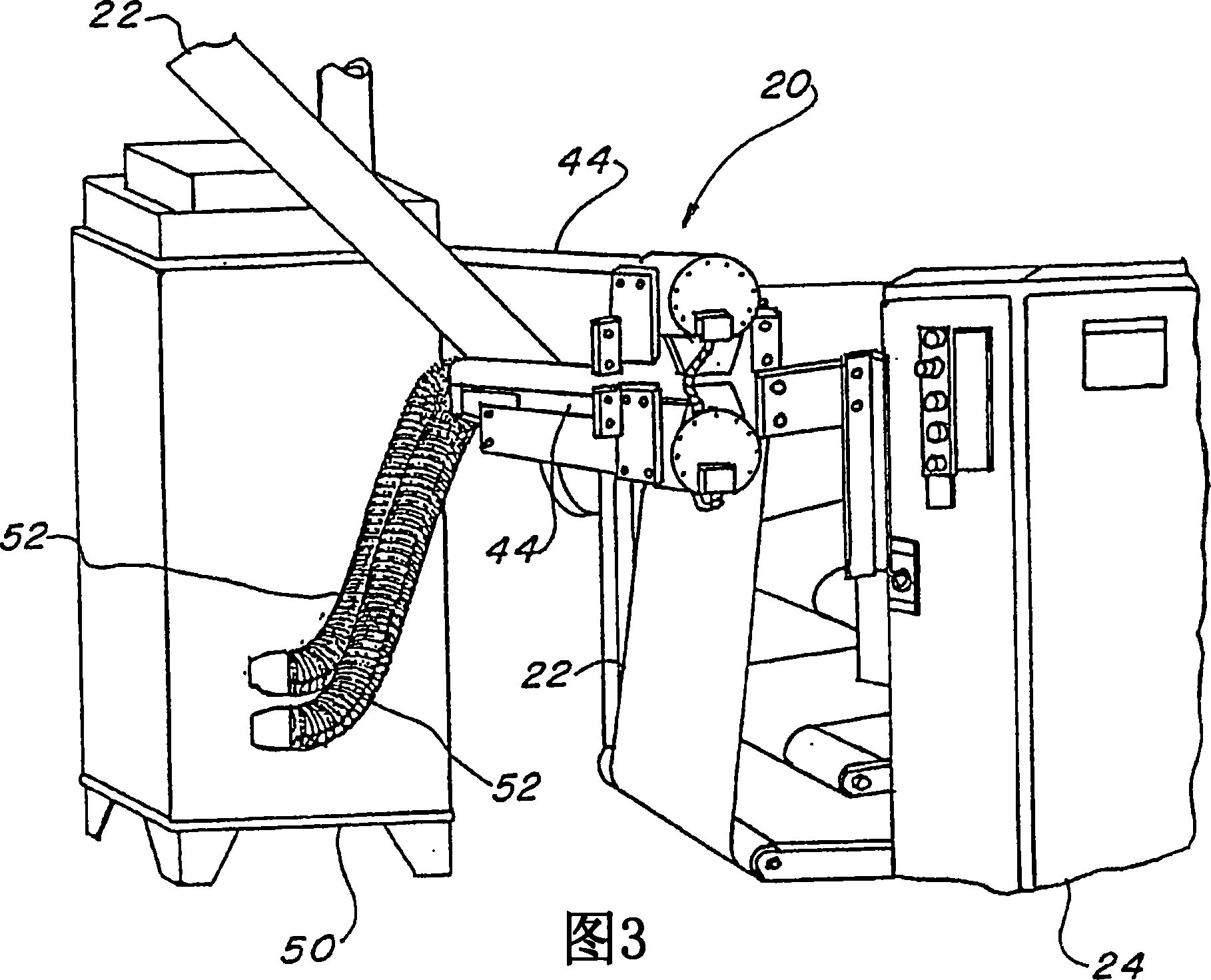

[0034] The best mode for carrying out the invention is as Figure 1-15 The preferred embodiment shown includes a cleaning device 20 for removing particles and other debris from a substrate web 22 used in a printing press 24 . It should be noted that although the invention has been specifically described for use with lithographic printing presses for offset printing, it is equally applicable to other printing presses or printing devices, including letterpress printing, flexographic printing, gravure printing , inkjet or laser printing, or any other device that employs a web that needs to be cleaned.

[0035] A plurality of track rollers 26, which are cylindrical in the present invention, such as figure 1 and 2 Between them, the web of substrate material 22 is held in tension as shown. The location of the track rollers 26 and their relative positions are determined by the construction of the printing press and can be varied to suit a particular application. Web 22 is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com