Method of washing fabric using machine and air type washing machine

A new method and technology for washing machines, which are applied to washing machines with containers, washing devices, textiles and paper making, etc., can solve the problems of large power consumption of washing machines, damage to clothing fibers, deformation and distortion, etc., and achieve simple structure and low power consumption. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

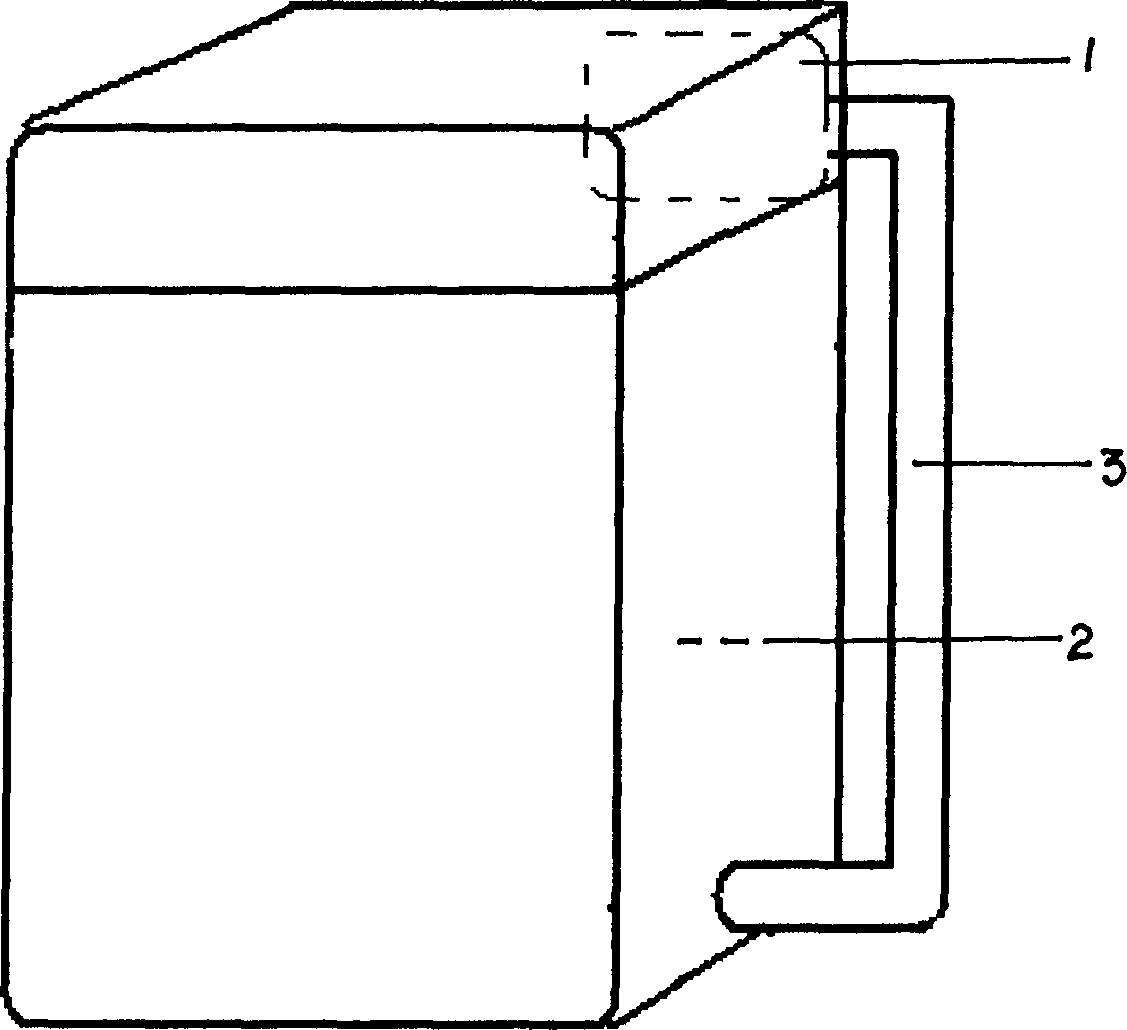

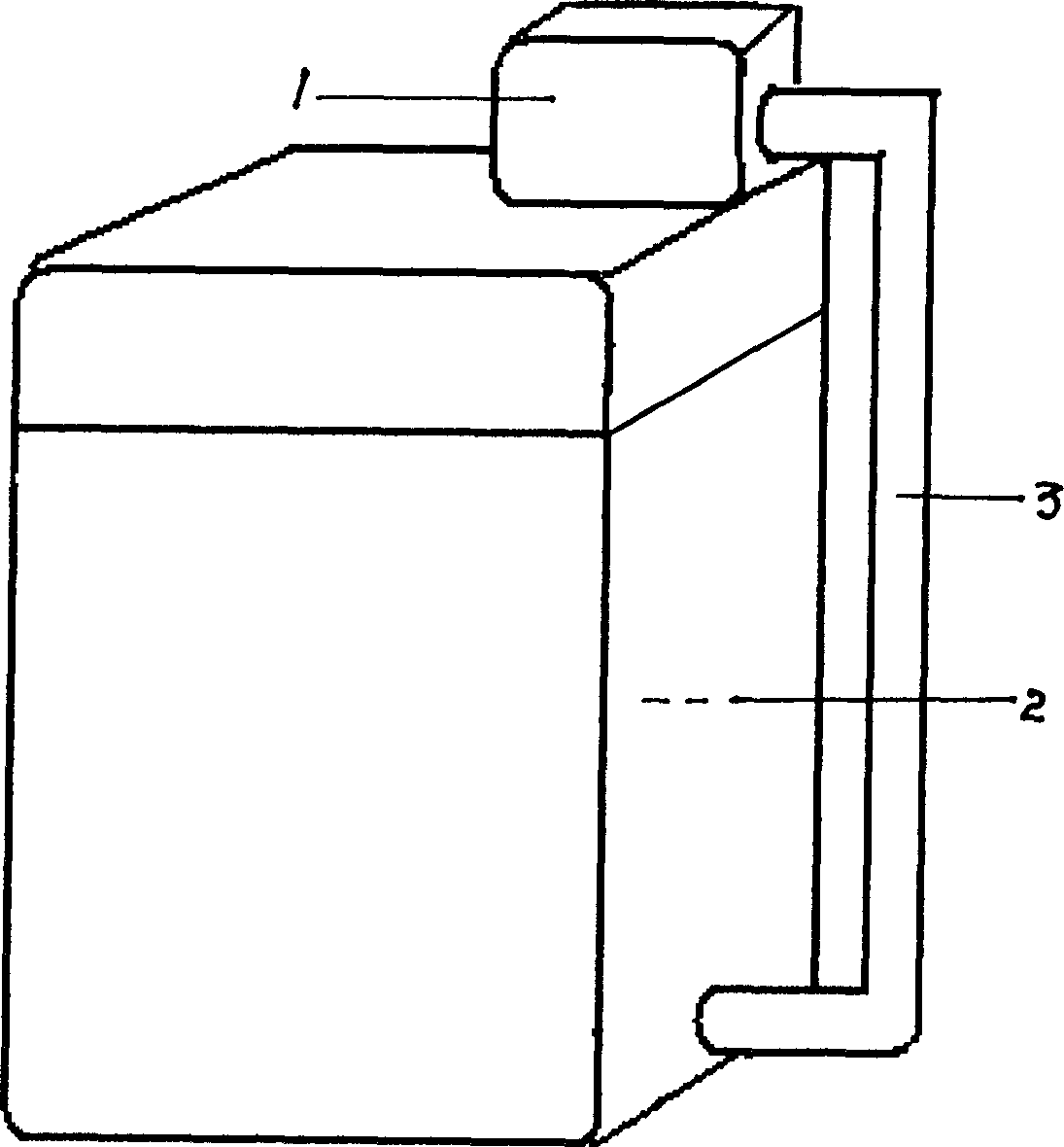

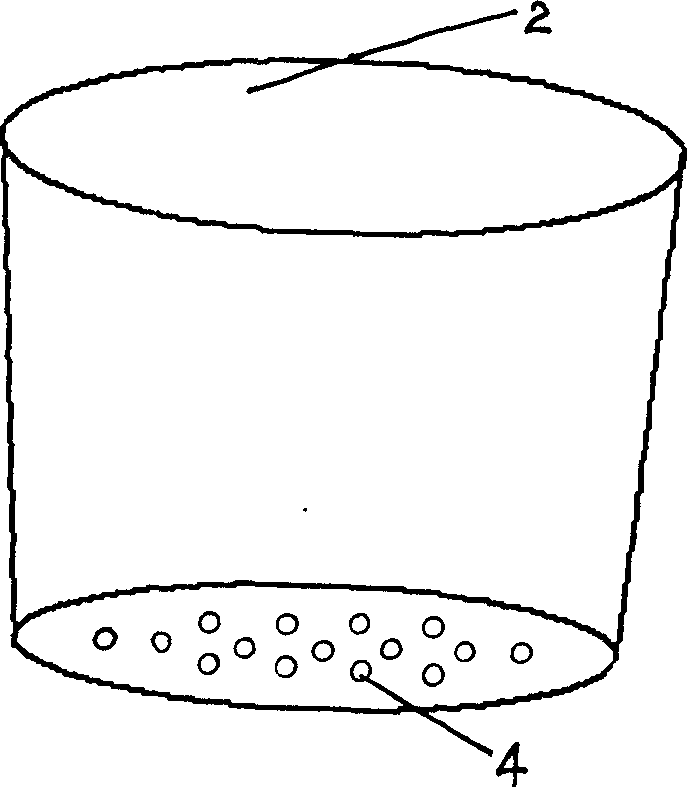

[0018] Such as figure 1 , figure 2 As shown, the air compressor 1 is arranged above the washing machine tub 2 to prevent the water in the washing tub from infiltrating into the air compressor. Hole 4 (comprising the air inlet pipe) communicates. another example image 3 As shown, the air intake holes can be distributed on the bottom, the lower peripheral wall, the bottom and the lower peripheral wall of the washing tub. The diameter of the air inlet holes ranges from 5 to 30 mm. It is determined that the general bottom area of the barrel is 1000Cm 2 , 6-12 air intake holes are set.

[0019] Now give another example of washing:

[0020] Take 3 pieces of moderately polluted clothes (about 1 catties) and put them into the washing bucket, open the drain valve to drain about 30 liters of water, put in 15 grams of washing powder, place a hollow pressure plate on the washed fabric, start the air compressor, and the air will flow from the washing machine The bottom of the buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com