Structure of gas-liquid separator with rotary dual cylinder compressor

A gas-liquid separator and compressor technology, which is applied in the field of compressors, can solve the problems of high cost, difficult installation, and easy resonance, etc., and achieve the effect of reducing the number or volume, easy installation and production, and saving pipe costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the invention content, characteristics and working process of the present invention, give examples of the following embodiments, and cooperate with the accompanying drawings to describe in detail as follows:

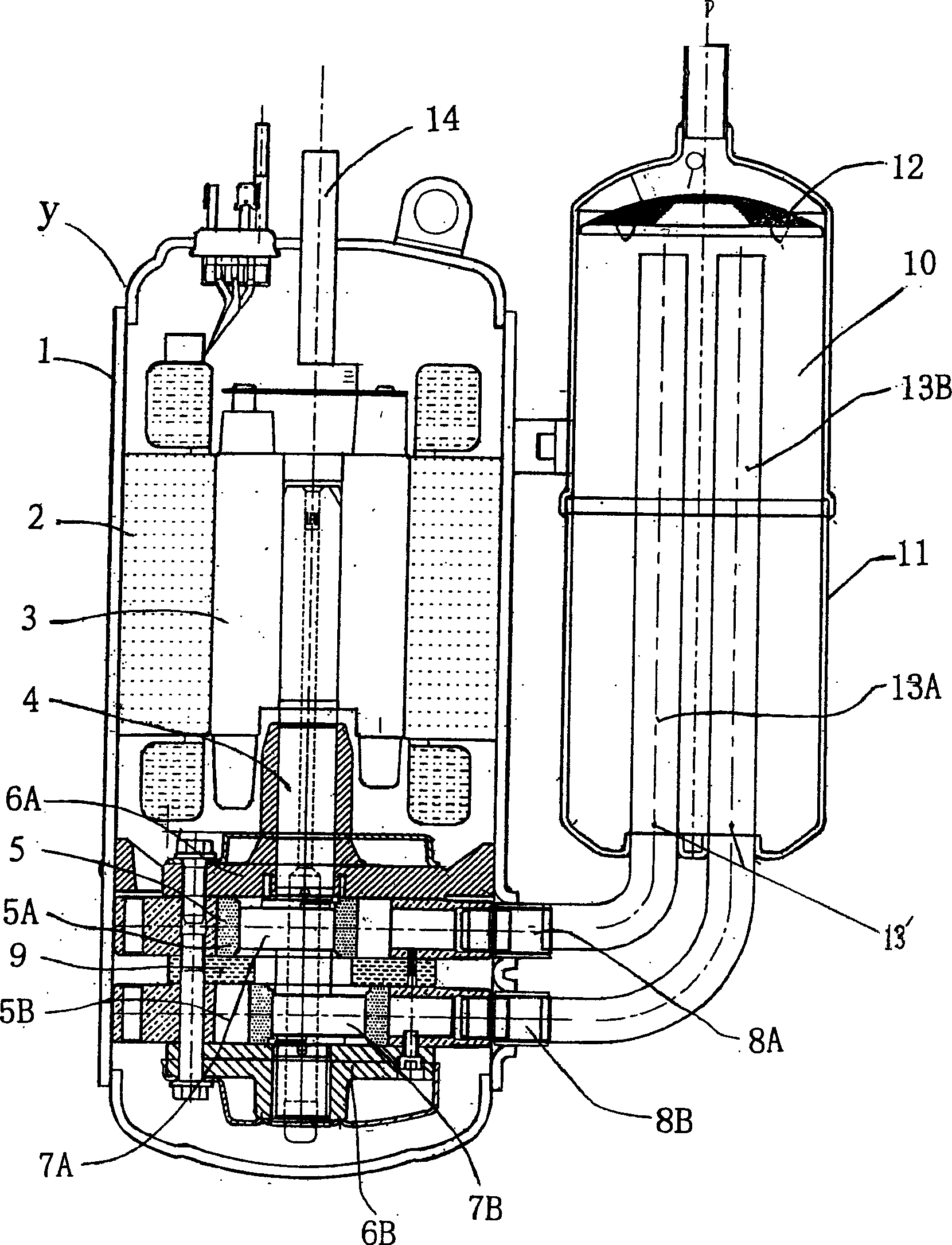

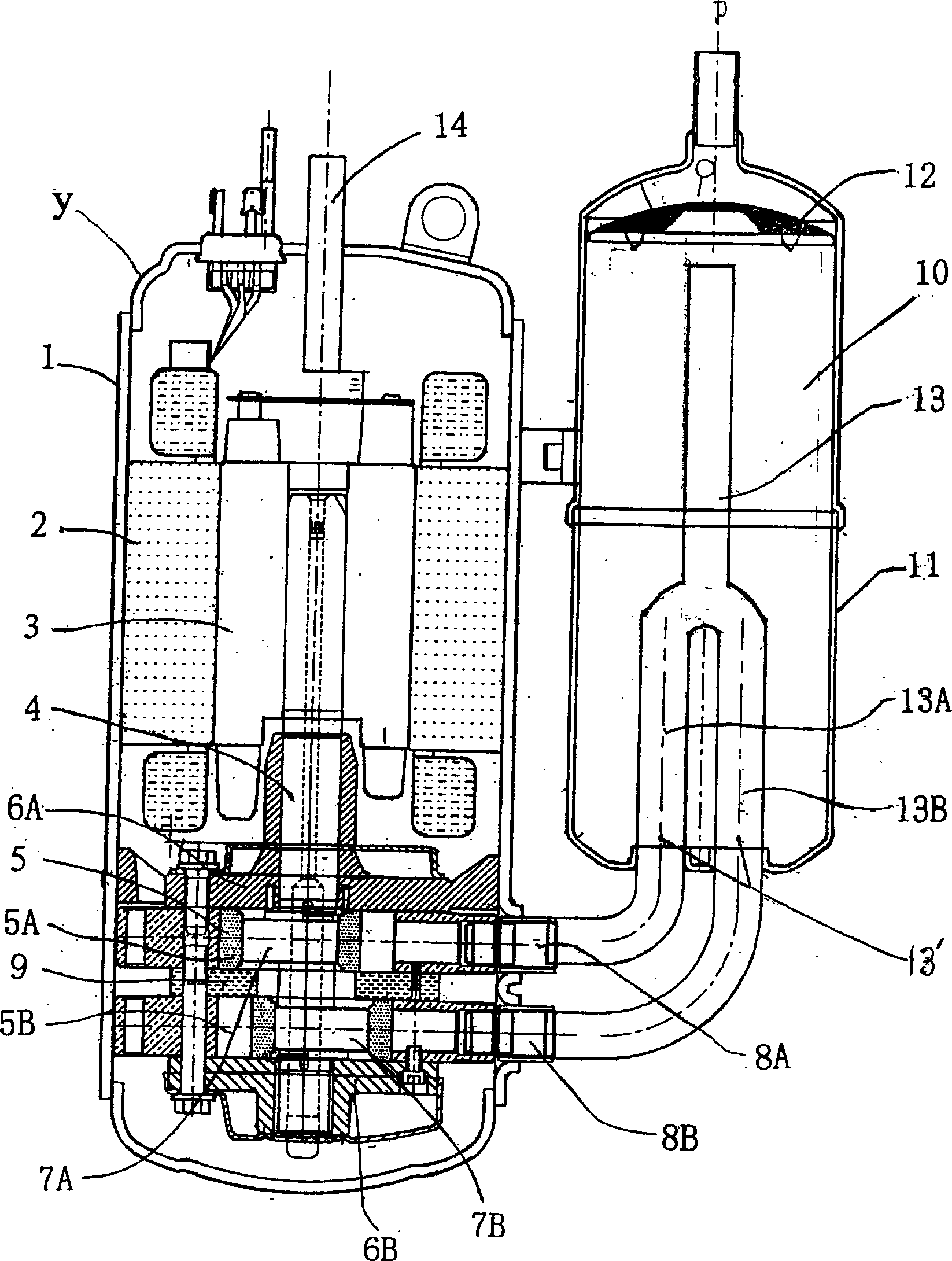

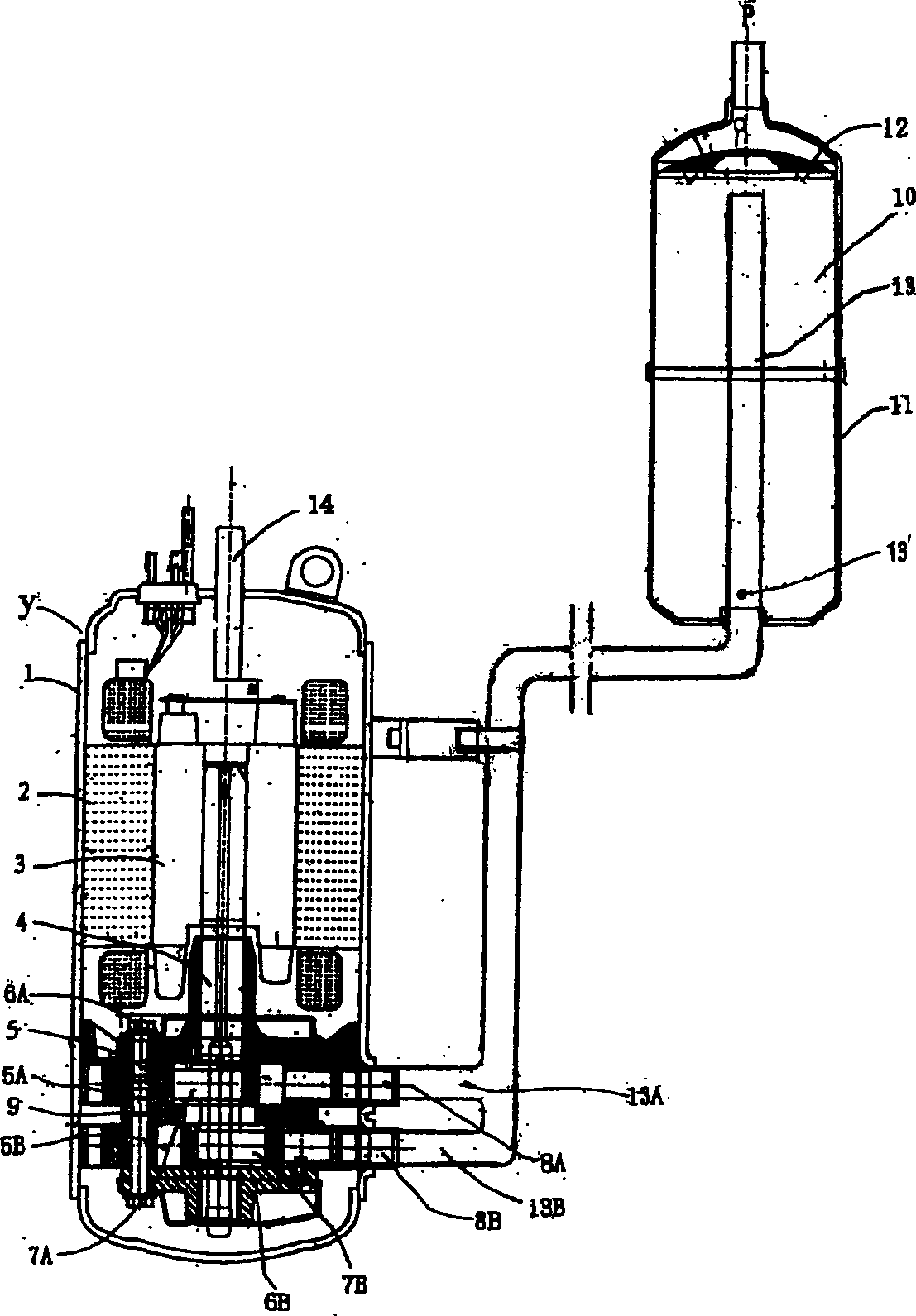

[0040] image 3 It is a structural diagram of the double-cylinder suction pipe of the separator of the present invention. The same symbols are used for the same parts as the previous technology

[0041] As shown in the figure, the rotary double-cylinder compressor according to the present invention consists of a casing 1; a stator 2 and a rotor 3 of the electric structural part are arranged inside the casing, wherein the center of the rotor 3 is pressed into the rotating shaft 4, and the center of the rotating shaft 4 The lower part is composed of a compression structure for sucking and compressing refrigerant gas.

[0042] The compression structure part includes a cylinder 5 fixed on the lower peripheral surface of the casing 1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com