Motor rotor counterbalance structure for compressor

A technology for motor rotors and balance weights, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as performance degradation, impact on refrigerant flow, excess heat, etc., reduce frictional heat generation and input work, and improve eddy current conditions , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

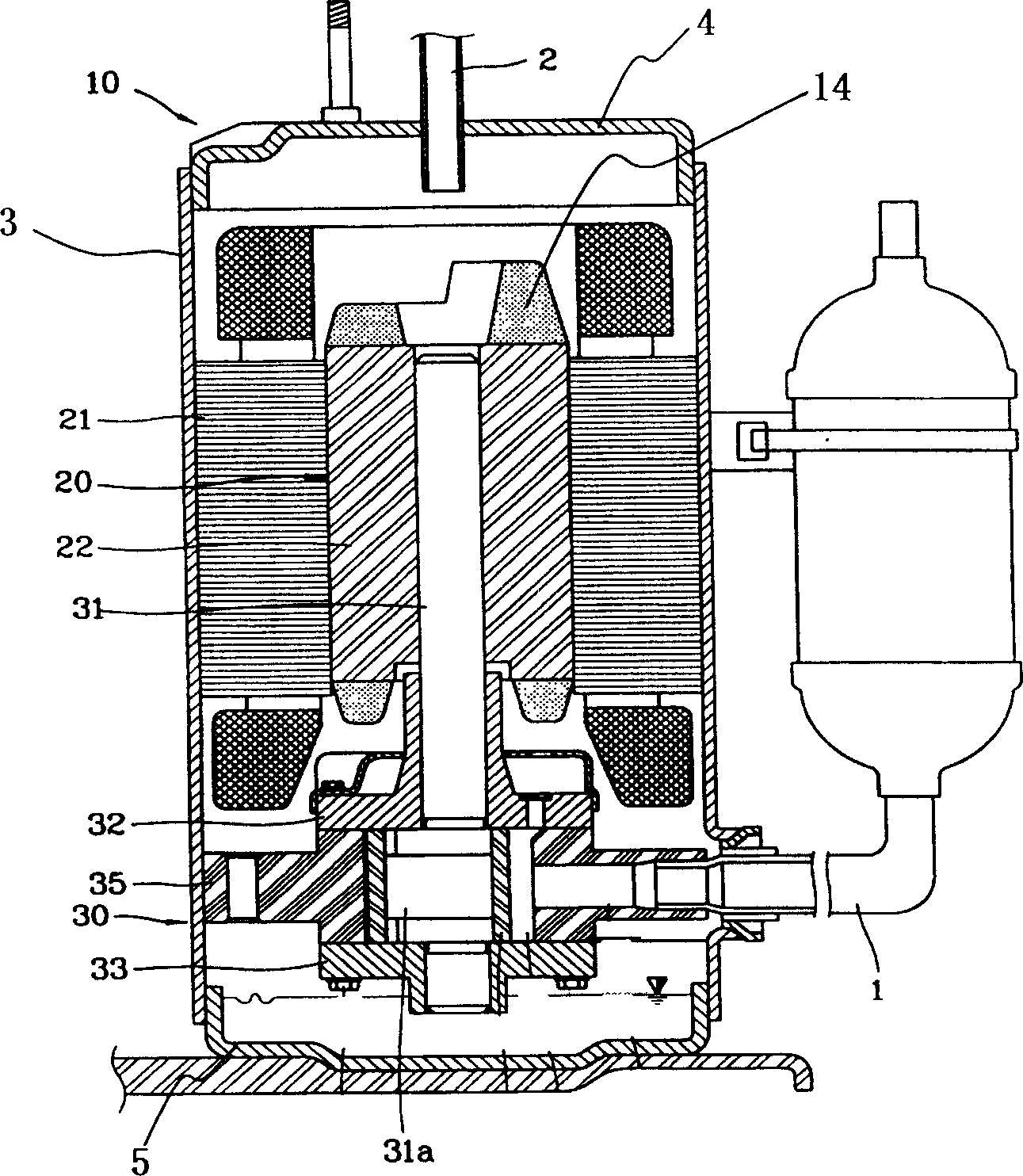

[0018] The structure of the motor rotor balance weight of the compressor of the present invention will be described in detail below with reference to the drawings and specific embodiments.

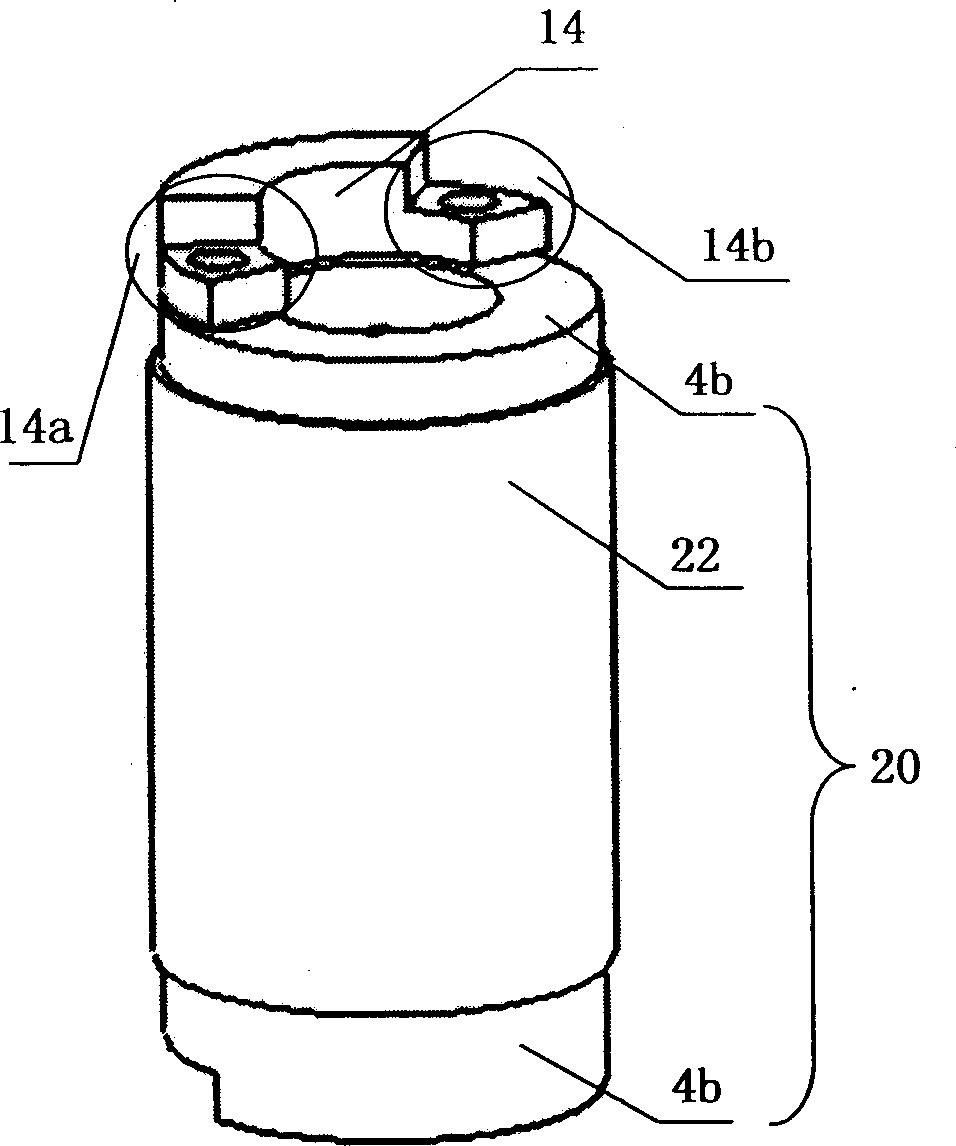

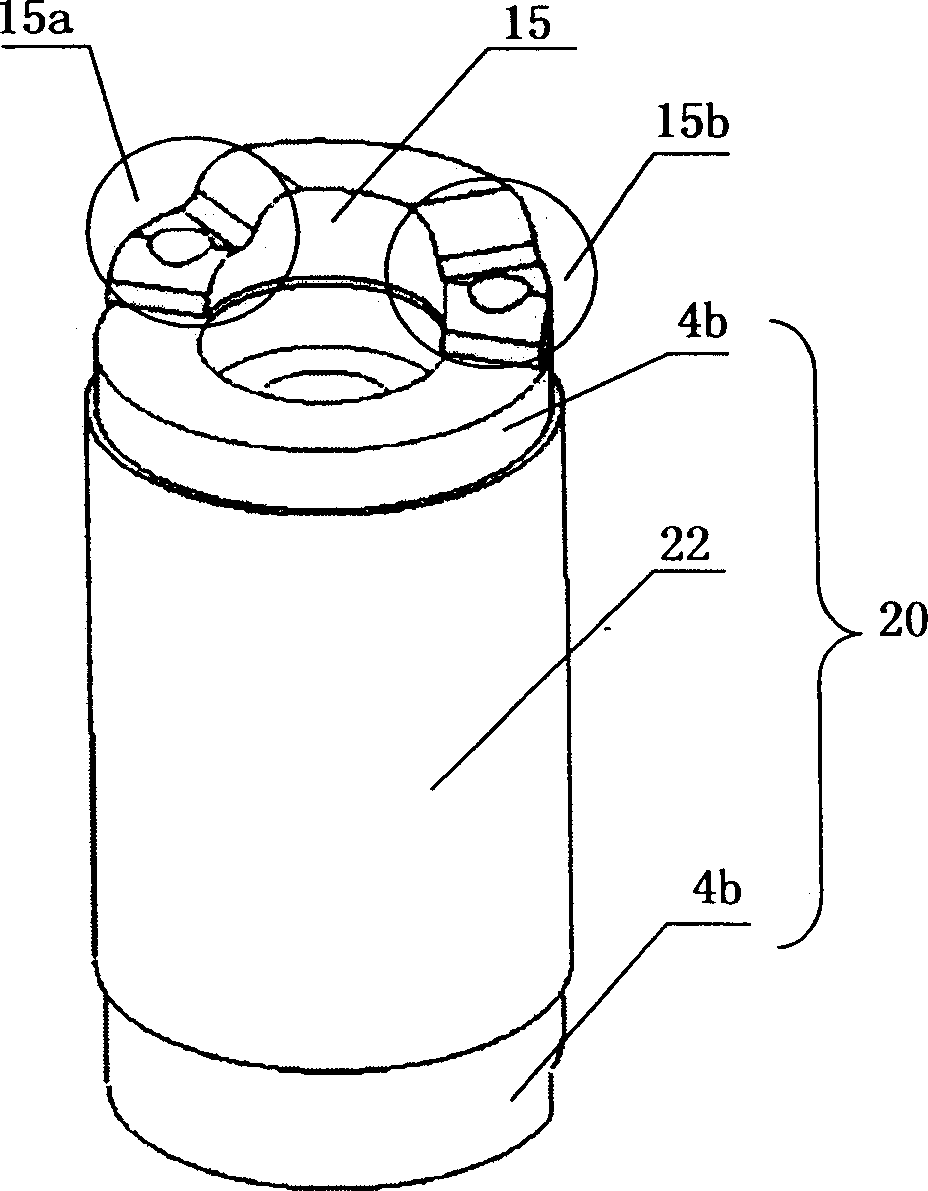

[0019] Such as image 3 As shown, the motor rotor balance weight structure of the compressor, the balance weight 15 is arranged on the upper end of the motor rotor 20 composed of the rotor iron core 22 and the cast aluminum 4b at the upper and lower ends of the compressor cavity, and is used to balance the motor rotor The structure of the balance weight 15 is that the windward surface 15a on one side of the balance weight 15 and the leeward surface 15b on the other side are circular arc streamlined ladder structures.

[0020] In this way, when the motor rotor 20 rotates, the friction between the balance weight and the refrigerant and other media can be minimized, reducing frictional heat generation and input work, thereby improving the overall performance of the compressor. Similarly, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com