Extraction method of polysaccharide from winter jujub

A technology of polysaccharide extraction and winter jujube, applied in chemical recovery and other directions, can solve the problems of limiting polysaccharide separation, purification, incomplete extraction and high energy consumption, and achieve the effects of low product cost, sufficient raw materials and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

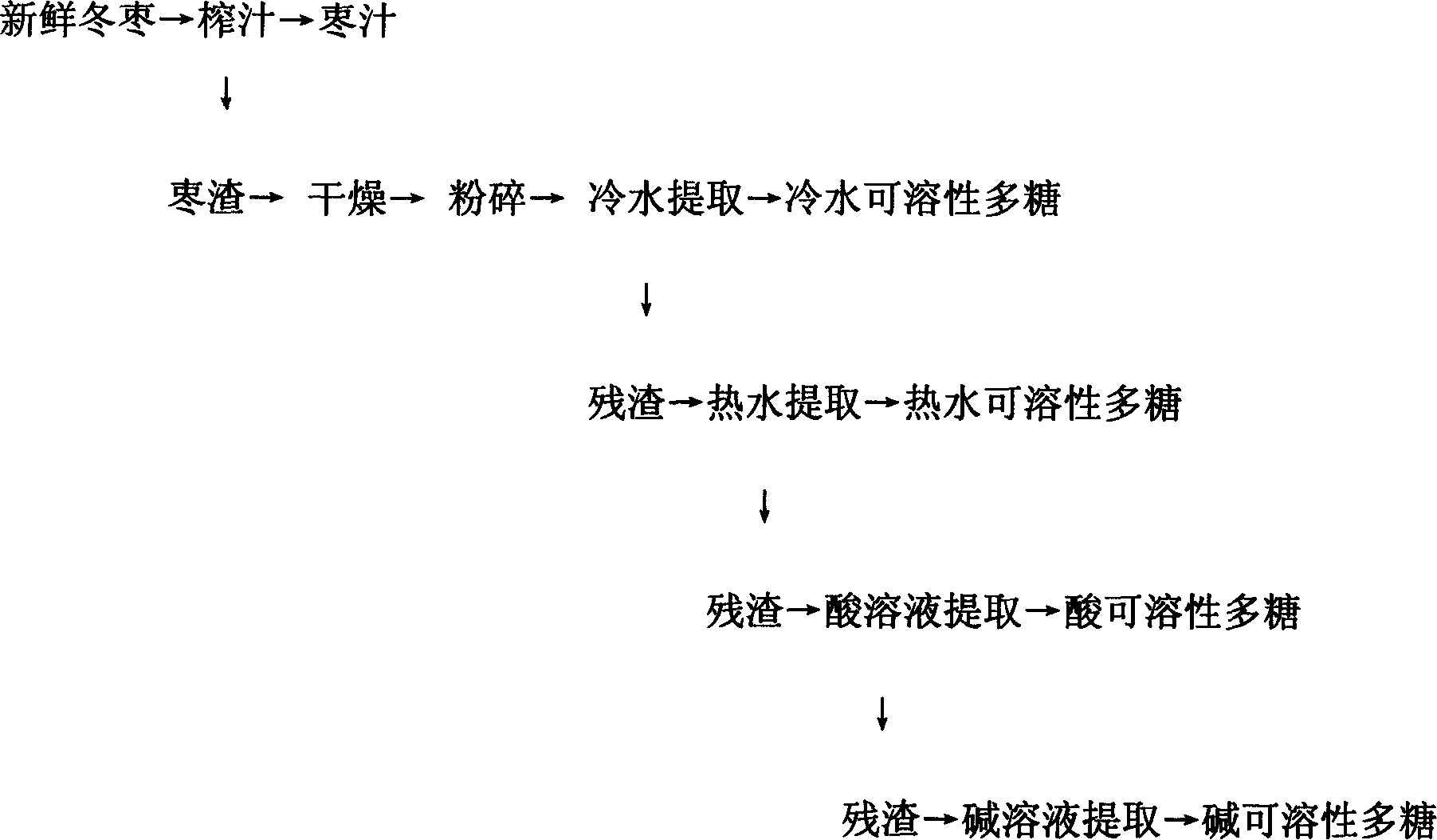

Method used

Image

Examples

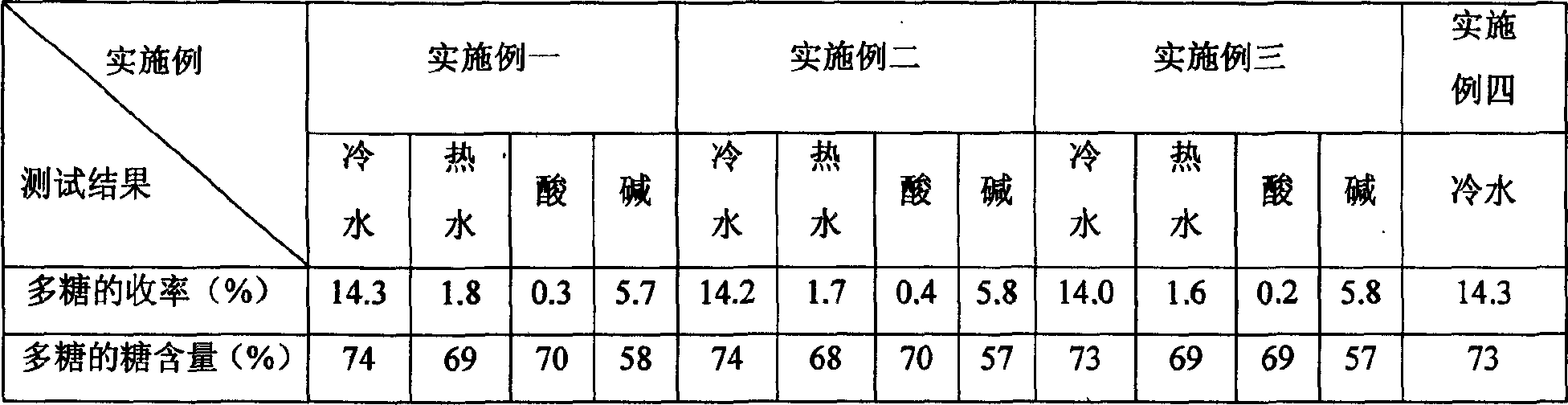

Embodiment 1

[0027] Crush fresh winter jujube, squeeze the juice, take 100g of jujube dregs, dry and pulverize, add 400ml of distilled water at 25°C for extraction, extract for 4 hours, and filter to obtain the filtrate and residue, repeat the extraction 4 times, concentrate the filtrate and combine it into 1 / 1 of the original volume 4. Precipitate and filter with ethanol with a volume ratio of 5 times (volume fraction is 80%), recover the precipitate, and obtain cold water-soluble polysaccharides and residues; add the residues to 90° C. 4 times the weight of distilled water for extraction, leaching for 2 hours, and filter. Obtain the filtrate and residue, repeat the extraction 4 times, concentrate the filtrate and merge it into 1 / 4 of the original volume, and use ethanol (volume fraction 80%) with a volume ratio of 5 times to carry out precipitation recovery to obtain hot water soluble polysaccharide and residue; Add 4 times the weight of the residue, extract in 0.05M hydrochloric acid sol...

Embodiment 2

[0030] Take dried winter jujube, crush and squeeze the juice, take 100g of jujube dregs, dry and pulverize, add 200ml of distilled water at 4°C, extract for 6 hours, filter to obtain the filtrate and residue, repeat the extraction 8 times, concentrate the filtrate and combine it into 1 / 6 of the original volume , use ethanol (volume fraction 90%) with a volume ratio of 2 times to precipitate, filter, and recover the precipitate to obtain cold water-soluble polysaccharides and residues; add the residues to distilled water with 2 times the weight of 100°C, extract for 6 hours, and filter to obtain the filtrate and the residue, repeated extraction 8 times, the filtrate was concentrated and combined into 1 / 6 of the original volume, and the ethanol (volume fraction was 90%) with a volume ratio of 2 times was used for precipitation and recovery, filtered to obtain hot water soluble polysaccharides and residues; Add 2 times the weight of the residue, extract in 0.01M hydrochloric acid ...

Embodiment 3

[0032]Take fresh winter jujube, crush and squeeze the juice, take 100g of jujube dregs, dry and crush, add 500ml of distilled water at 15°C, extract for 2 hours, filter to obtain the filtrate and residue, repeat the extraction twice, concentrate the filtrate and combine it into 1 / 6 of the original volume , Precipitate with ethanol (60% by volume) with a volume ratio of 2 times, filter, and recover the precipitate to obtain cold water-soluble polysaccharides and residues; add the residues to 5 times the weight of distilled water at 70°C, extract for 2 hours, and filter to obtain the filtrate and residue, repeated extraction twice, concentrating and merging the filtrate into 1 / 6 of the original volume, using ethanol (volume fraction 60%) with a volume ratio of 2 times for precipitation recovery, filtering to obtain hot water soluble crude polysaccharide and residue; Add the residue to 5 times the weight, extract in 1.00M calcium hydroxide solution (70°C), extract for 2 hours, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com