Self-short-circuit type coaxial shock wave electric probe and method for manufacturing same

An electrical probe, coaxial type technology, applied in the direction of material analysis by electromagnetic means, material analysis using wave/particle radiation, measurement device, etc., can solve the consistency and reliability uncertainty of coaxial shock wave electric probe and other problems, to achieve the effect of good repeatability of test parameters, good electrical insulation, and easy placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

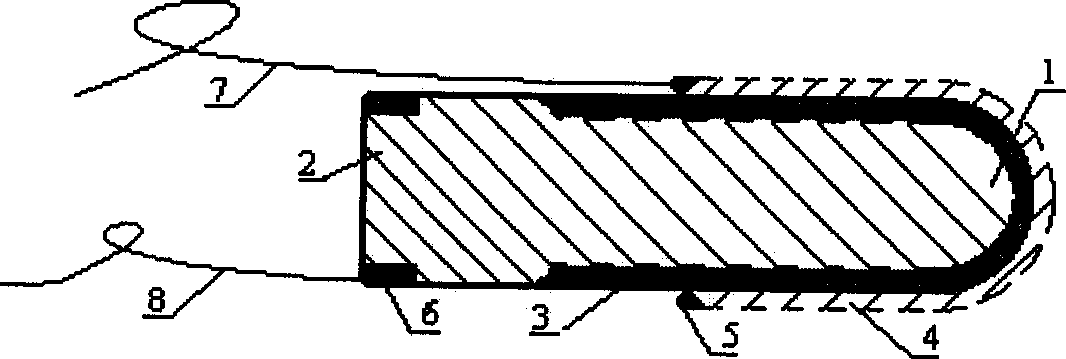

[0038] The self-short-circuit coaxial shock wave electric probe of the present invention is manufactured by aluminum anodization-chemical deposition film technology, and the aluminum alloy wires of φ1 mm are bundled together, and then processed into 35 mm aluminum short rods by electric sparks, according to the following process Step operation:

[0039] (1) Mechanical polishing and degreasing: Clamp the aluminum short rod with a small vertical drilling machine fixture, fold it into 60° with 800 mesh fine sandpaper, and carefully grind one end of the aluminum short rod into an aluminum semicircle head 1, and strive to achieve 11 smoothness at this end 0.3, the other end is an aluminum flat end 2, remove the dirt on the surface of the short aluminum rod with a neutral detergent, and rinse it with tap water for 1 minute;

[0040] (2) Chemical descaling-alkali cleaning: Use a resistance heating mantle, temperature controller and micro-stirrer to control the temperature at a const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com