Protein food material having controlled hydrogen sulfide odor and method of controlling hydrogen sulfide odor

A hydrogen sulfide and protein technology, used in protein food processing, protein food ingredients, animal protein processing, etc., can solve problems such as poor effect, inability to completely control odor, and prolong production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

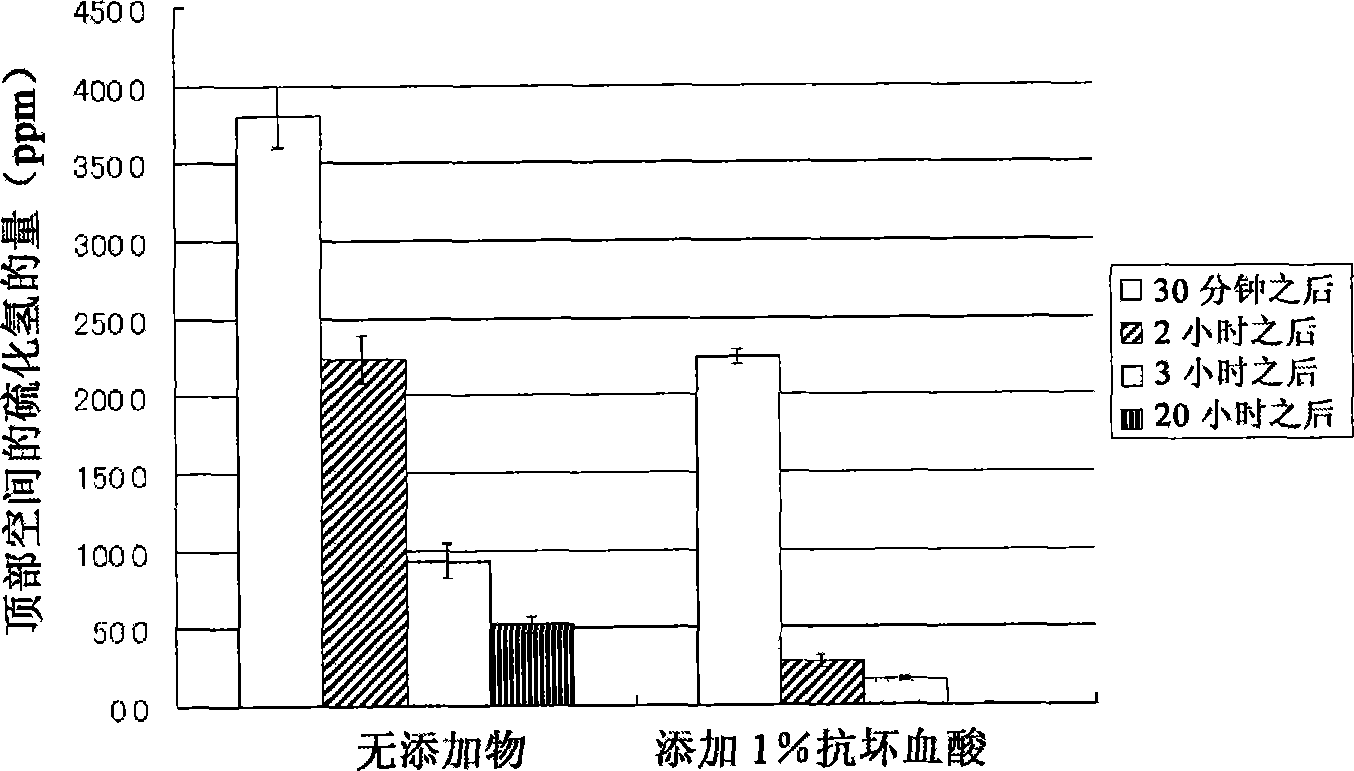

[0036] Deodorizing Effect of Adding Ascorbic Acid to Fish Protein

[0037] (method)

[0038] A high-temperature and high-pressure processed model sample was prepared by the same method as in Example 1 using the raw meat sauce. In this protocol, the heating condition was set at 160 °C for 10 minutes. The amount of hydrogen sulfide generated was measured for a sample to which nothing was added to the meat sauce (no additive) and a sample to which 1% ascorbic acid was added. At 30 minutes, 2 hours, 3 hours and 20 hours after the end of heating, the amount of hydrogen sulfide was measured by the same method as in Example 1.

[0039] (result)

[0040] The results are shown in figure 2 . The sample with no additions to the meat sauce showed about 50 ppm residual hydrogen sulfide even after 20 hours of refrigeration. When the sample was supplemented with ascorbic acid, the residual amount of hydrogen sulfide was less than that without the addition at 30 minutes after heating, ...

Embodiment 3

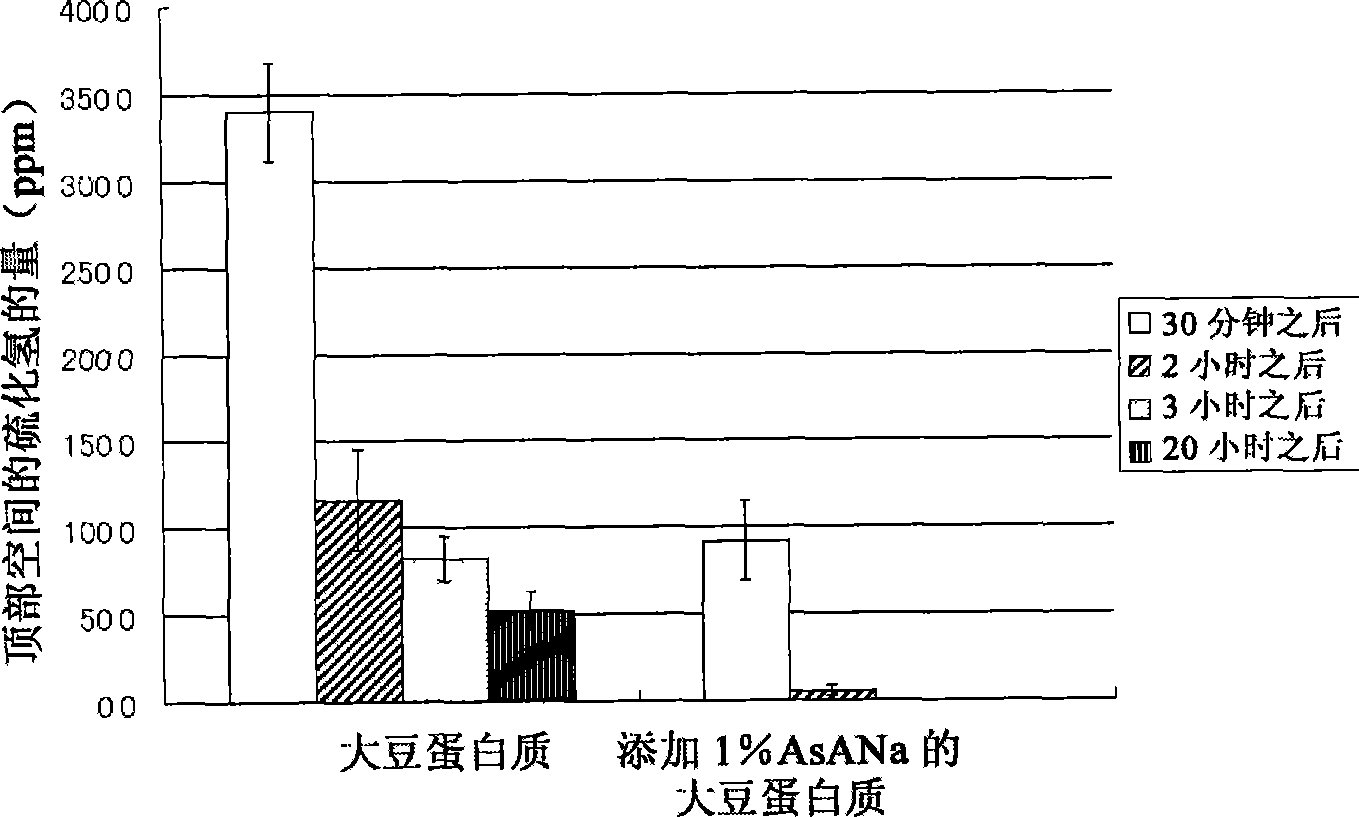

[0043] The amount of hydrogen sulfide produced and the deodorizing effect of sodium ascorbate in the case of using soybean protein as a raw material

[0044] (method)

[0045] A model sample subjected to high temperature and high pressure processing was prepared by the same method as in Example 1. Soybean protein is used as a raw material and heated after adjusting its water content to 70%. The amount of hydrogen sulfide was compared between a sample to which no ascorbic acid was added and a sample to which 1% sodium ascorbate was added. At 30 minutes, 2 hours, 3 hours and 20 hours after the end of heating, the amount of hydrogen sulfide was measured.

[0046] (result)

[0047] The results are shown in image 3 . The sample without any addition to the soy protein showed a residual amount of hydrogen sulfide of about 50 ppm even after refrigerated for 20 hours. When the sample was supplemented with ascorbic acid, the residual amount of hydrogen sulfide was less than that ...

Embodiment 4

[0050] Comparison with secondary deodorizing processing method (method of Japanese Patent No. 2941416)

[0051] (method)

[0052] A high-temperature and high-pressure processed model sample was prepared by the same method as in Example 1 using the raw meat sauce. The HPHT-processed samples without any additions to the meat sauce were frozen at -25°C and then boiled in 10 times the volume of hot water for 1 hour. After this boiling and subsequent cooling process, the amount of hydrogen sulfide was determined. For the sample to which ascorbic acid was added, the amount of hydrogen sulfide was measured by the same method as Test Example 1 after refrigerating for 20 hours.

[0053] (result)

[0054] Table 1 shows the comparison results of the residual hydrogen sulfide of the secondary processing scheme and the scheme of adding ascorbic acid. When secondary processing (such as freezing, thawing, and boiling) was performed, residual hydrogen sulfide of about 20 ppm was observed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com