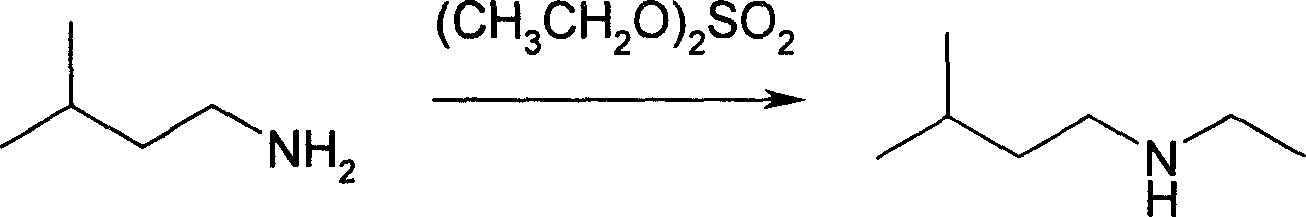

Production method of N-ethyl iso penlyl amine and its device

A technology of ethyl isoamylamine and its production method, which is applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve problems such as no continued utilization of monoethyl sulfate, high toxicity of diethyl sulfate, etc. Achieve the effects of large-scale production, easy control of reaction conditions, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

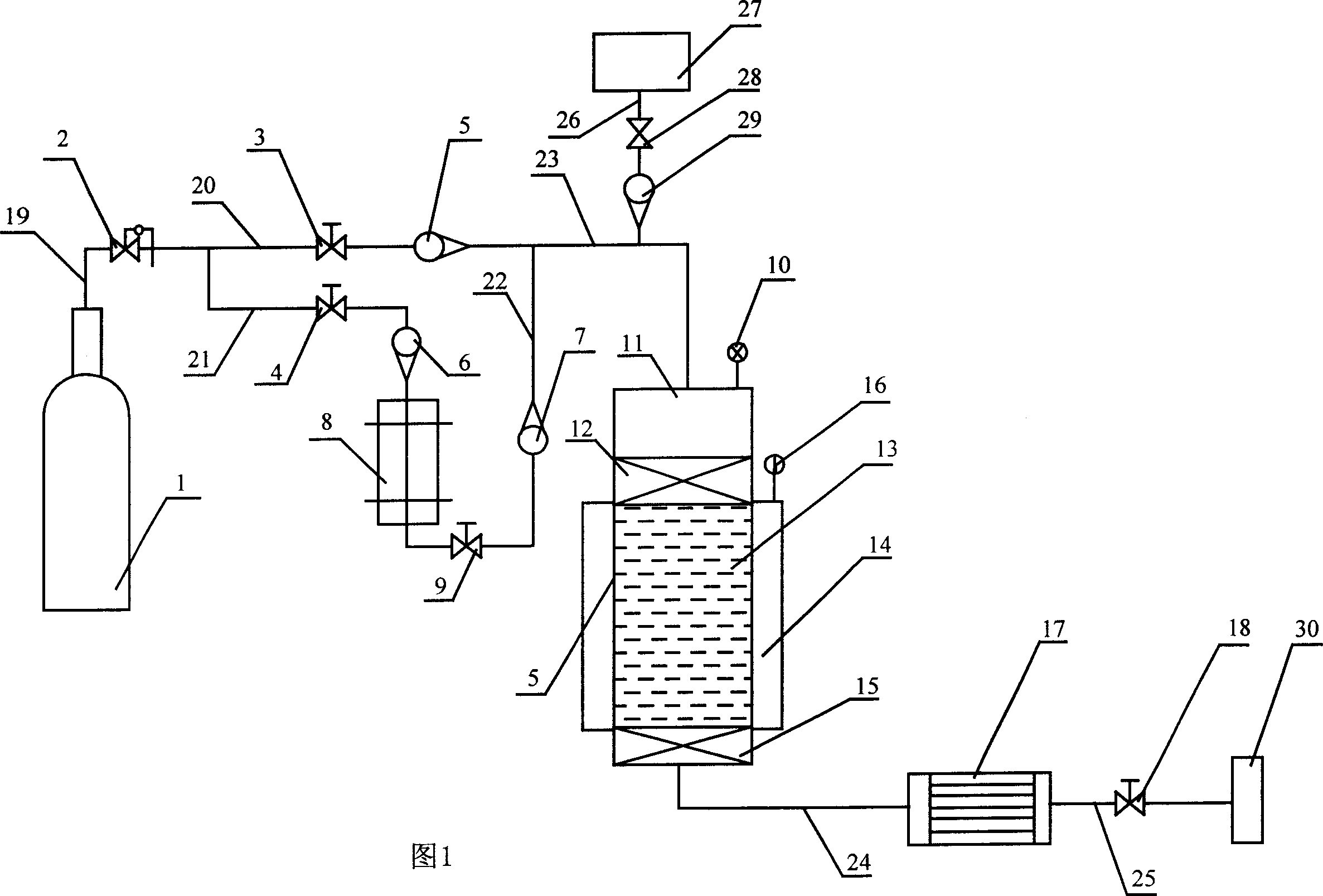

[0043] Embodiment 1, the production method of N-ethylisoamylamine of the present invention, then carry out following steps successively:

[0044] 1), close stop valve 28, make stop valve 3, 4, 9, 18 all be in open state; Add isoamyl alcohol 88g (1mol) respectively in metering tank 8, ethylamine 90g (2mol), form mixed solution;

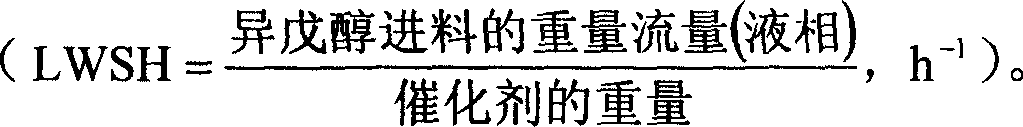

[0045] 2), the H in the high-pressure gas storage tank 1 2 After passing through the pipeline 19, it enters the pressure reducing valve 2 for decompression treatment. The pressure value set by the pressure reducing valve 2 is the working pressure in the following aminolysis reaction. A part of H from pressure reducing valve 2 2 Directly through line 20 to header 23, H 2 The flow rate is controlled by flow meter 5. Another part that comes out from decompression valve 2 enters metering tank 8 through pipeline 21, and this part H 2 The flow rate is controlled by flow meter 6; this part H 2 Push the mixed liquid in the metering tank 8 to flow to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com