Automatic control method for central cold supply system

An automatic control, central cooling technology, applied in heating and ventilation control systems, heating and ventilation safety systems, household heating, etc. Clear goals, energy-saving operating costs, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

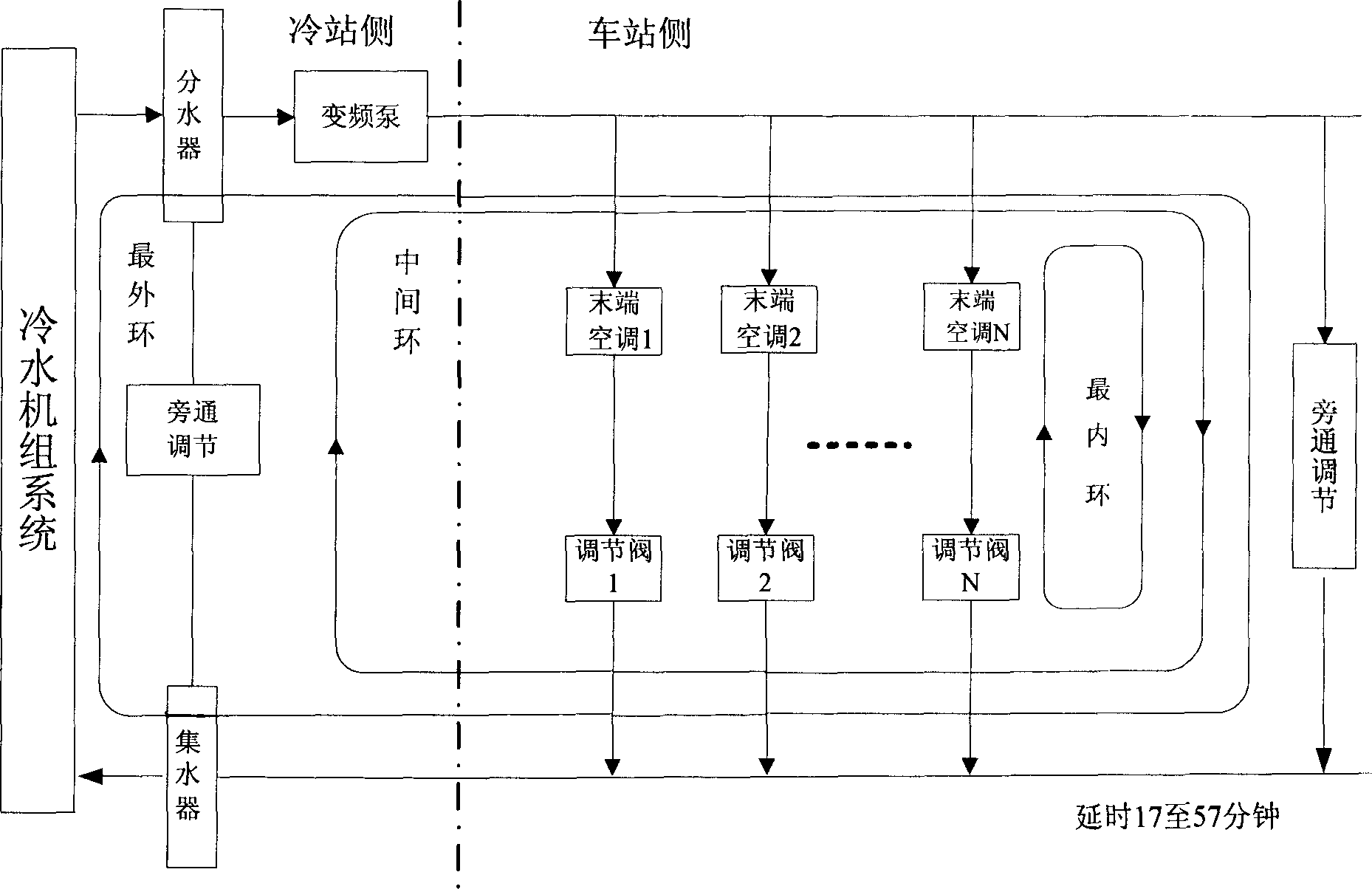

[0034] Such as figure 1 As shown, the air-conditioning water supply system of the entire cold station is decomposed into a three-loop regulation system. According to the idea of principal component analysis, many control objects and process control parameters in the system are decomposed and considered, so that the chiller group control, frequency conversion The pump control and regulating valve control are relatively independent and interdependent, and the control objectives are clear. The specific description is as follows:

[0035] 1. Decoupling of control objects and control variables

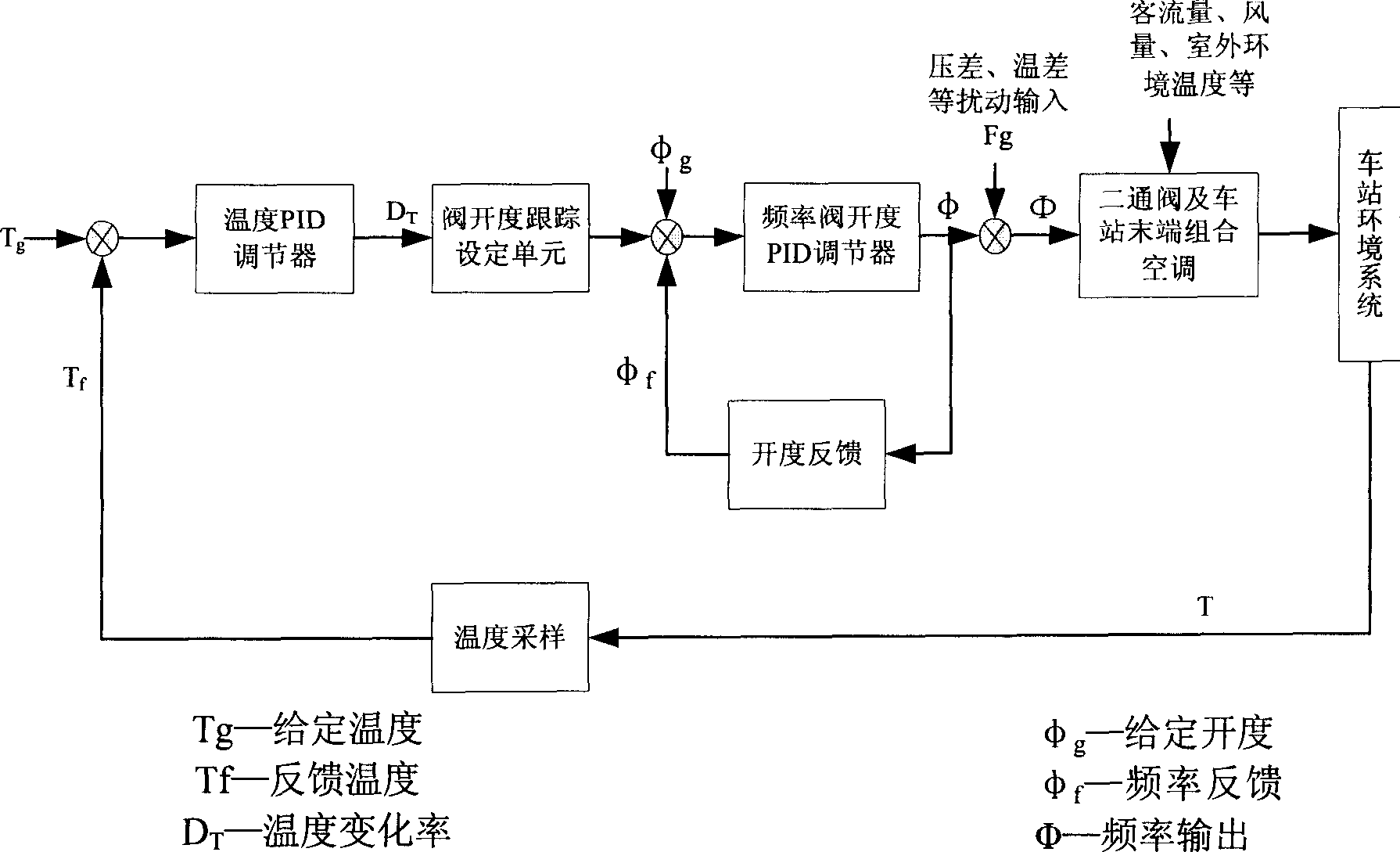

[0036] 1) Take the control of the terminal air conditioner and its control valve as the inner loop, take the ambient temperature as the control variable, the opening of the control valve as the adjustment variable, and others such as: chilled water temperature, station passenger flow, chilled water pressure difference, etc. as disturbance variables ;

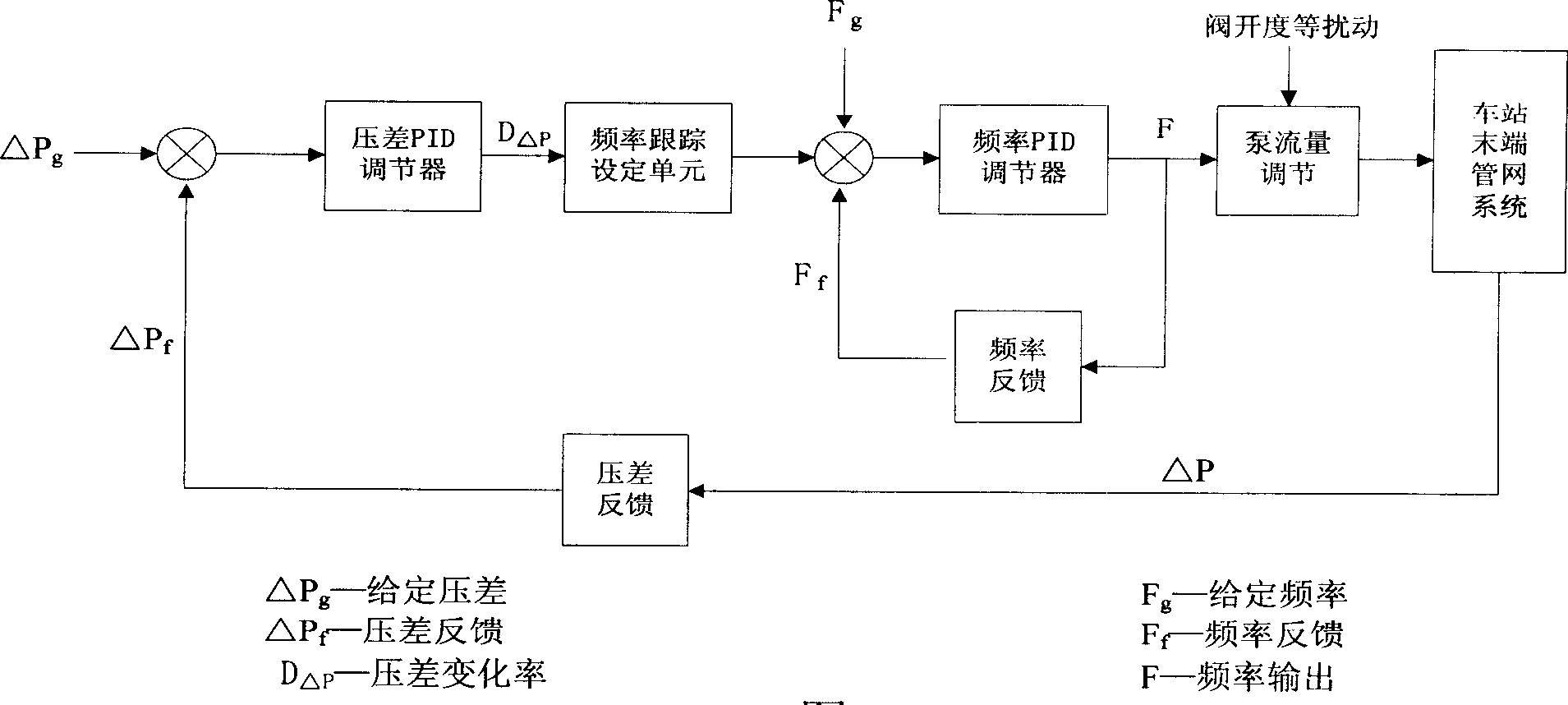

[0037] 2) The control of the vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com