Reflection white-light LED excited by fluorescent powder

A light-emitting diode and reflective technology, which is applied in the direction of reflectors, semiconductor devices of light-emitting elements, light sources, etc., can solve the problems of phosphor degradation, increased process complexity, and yield decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above and other objectives and advantages of the present invention will be described in detail below in conjunction with the drawings, detailed description of the embodiments and scope of claims. It should be noted that each drawing is provided for illustrating the essence of the present invention, and should not be regarded as a definition of the scope of the present invention. For a definition of the scope of the invention, reference is made to the claims.

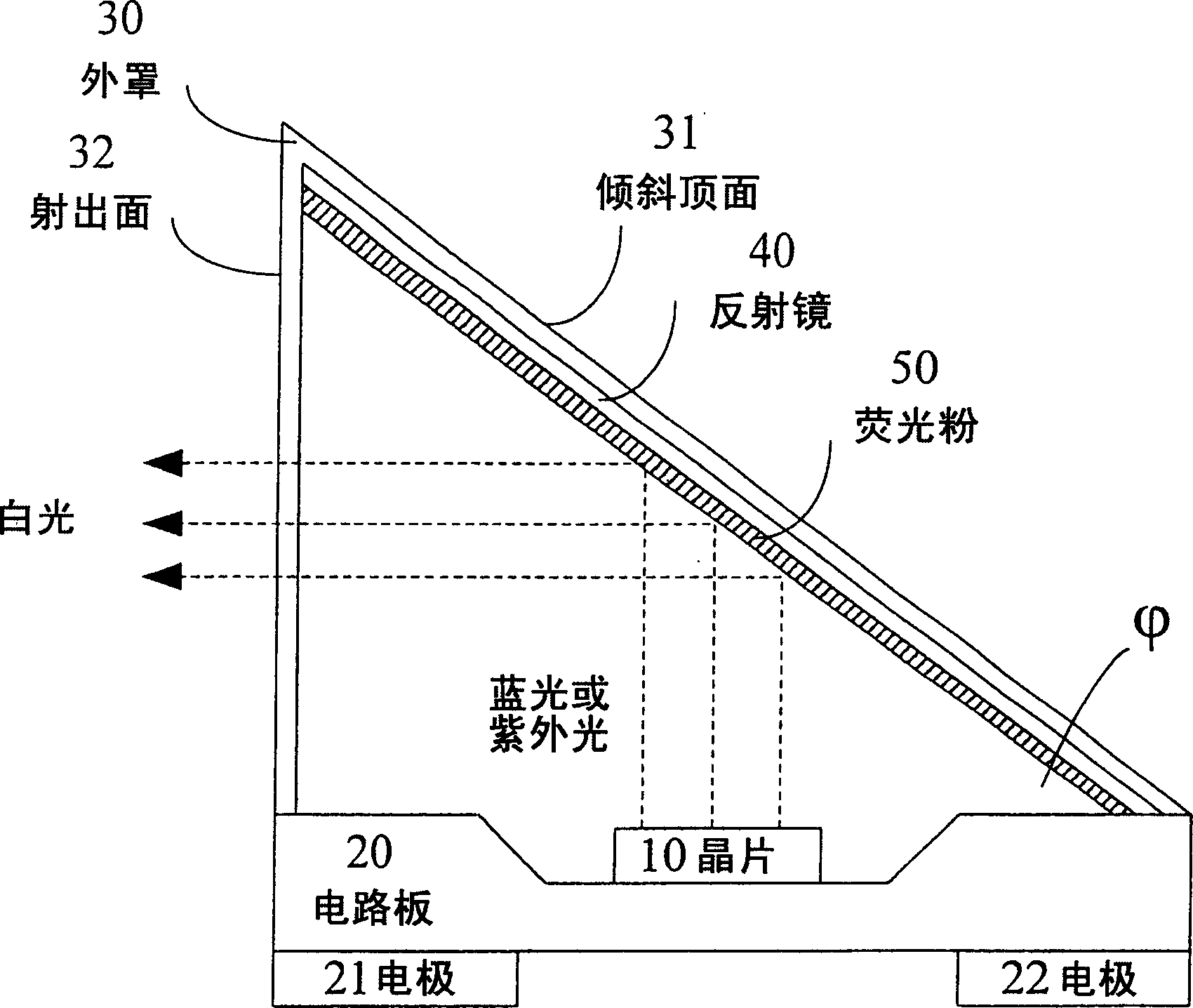

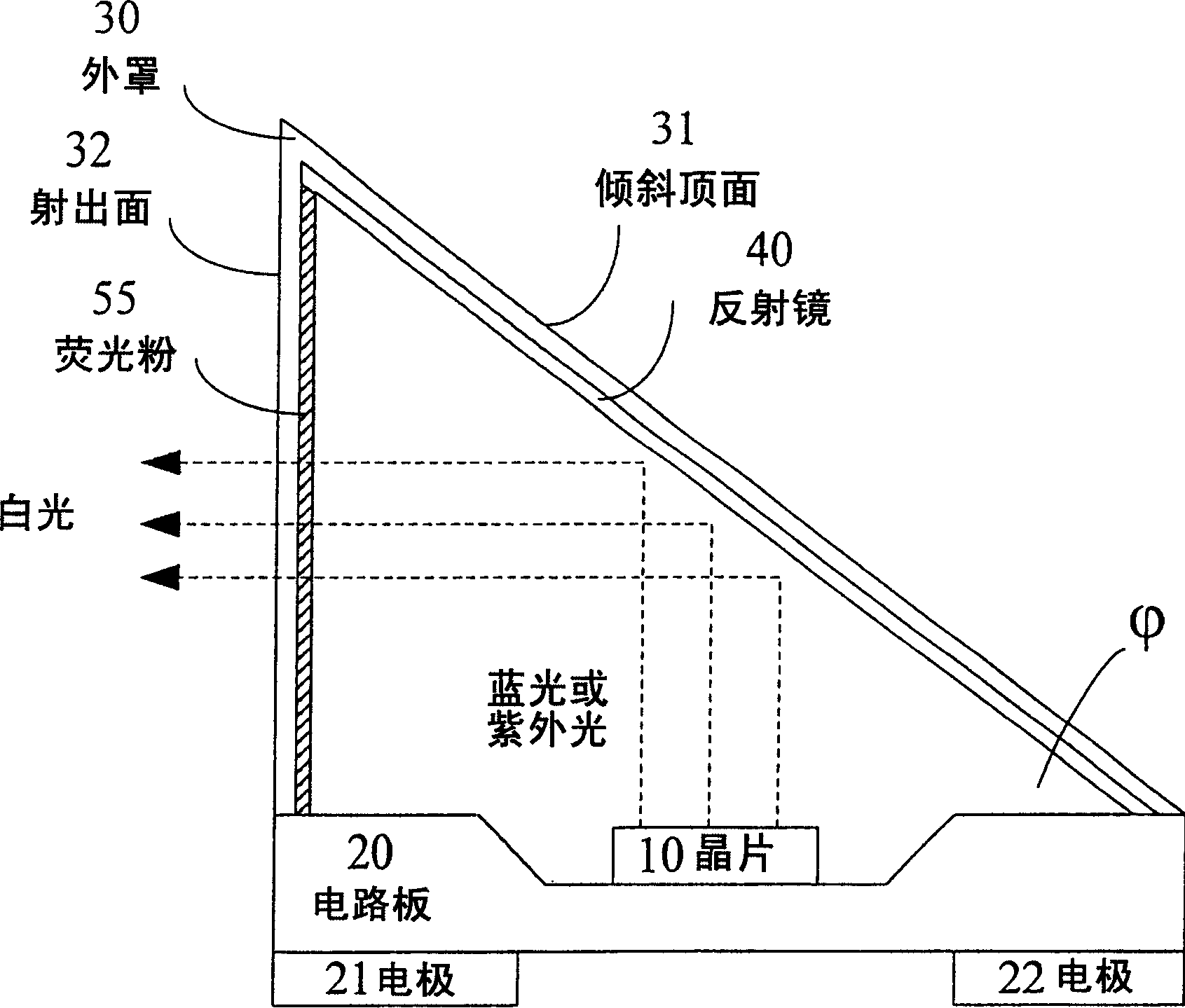

[0026] Figure 1a , Figure 1b It is a side view and a front view respectively showing the white light emitting diode according to the first embodiment of the present invention. As shown in the figure, in the white light emitting diode proposed by the present invention, the conventional blue or ultraviolet light emitting diode chip 10 is disposed on the circuit board 20 having positive and negative electrodes 21 and 22 . When an external voltage is applied to the positive and negative electrodes 21 and 22, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com