Double surface self-adhesive rubber modified asphalt PP tyre water-proof coiled material

A self-adhesive rubber, modified asphalt technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of poor waterproof effect, easy hollowing or peeling, etc., to achieve easy bending, improve water channeling resistance, and facilitate construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

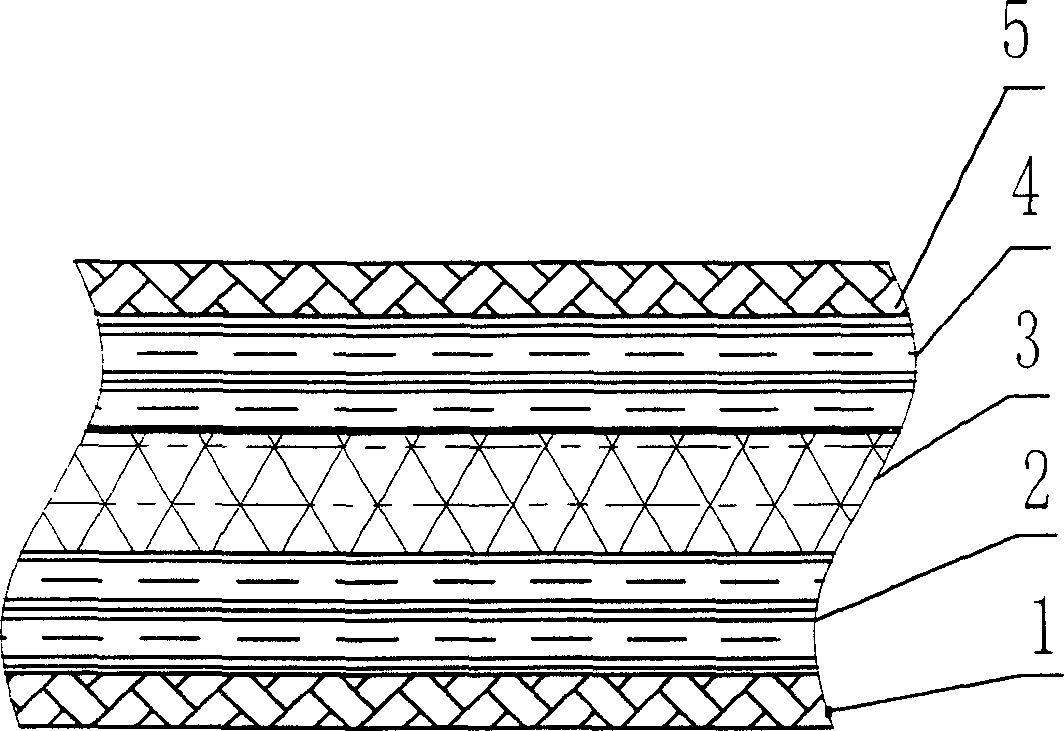

[0008] according to figure 1 The specific structure and working process of the present invention will be described in detail. The roll material includes a base layer 3, a self-adhesive material layer and upper and lower isolation layers 5,1. Wherein the base layer 3 is made of polypropylene braid, and the specifications and models of the polypropylene braid should be determined according to the actual performance requirements of the coiled material. The upper and lower sides of the base layer 3 made of polypropylene braid are evenly coated with a hydrophilic upper self-adhesive rubber-modified asphalt mixture layer 2 and a lower self-adhesive rubber-modified asphalt mixture layer 4. The thicknesses of the upper self-adhesive rubber-modified asphalt mixture layer 2 and the lower self-adhesive rubber-modified asphalt mixture layer 4 on both sides of the base layer 3 are set according to needs and possibility. The outer surface of each material layer is pasted with commonly use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com