Shipping power station integrated test system

A comprehensive test and power station technology, which is applied in the field of dock testing of large and medium-sized shipyards in shipbuilding, and can solve problems such as electrical faults of control circuits and mechanical faults of transmission mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

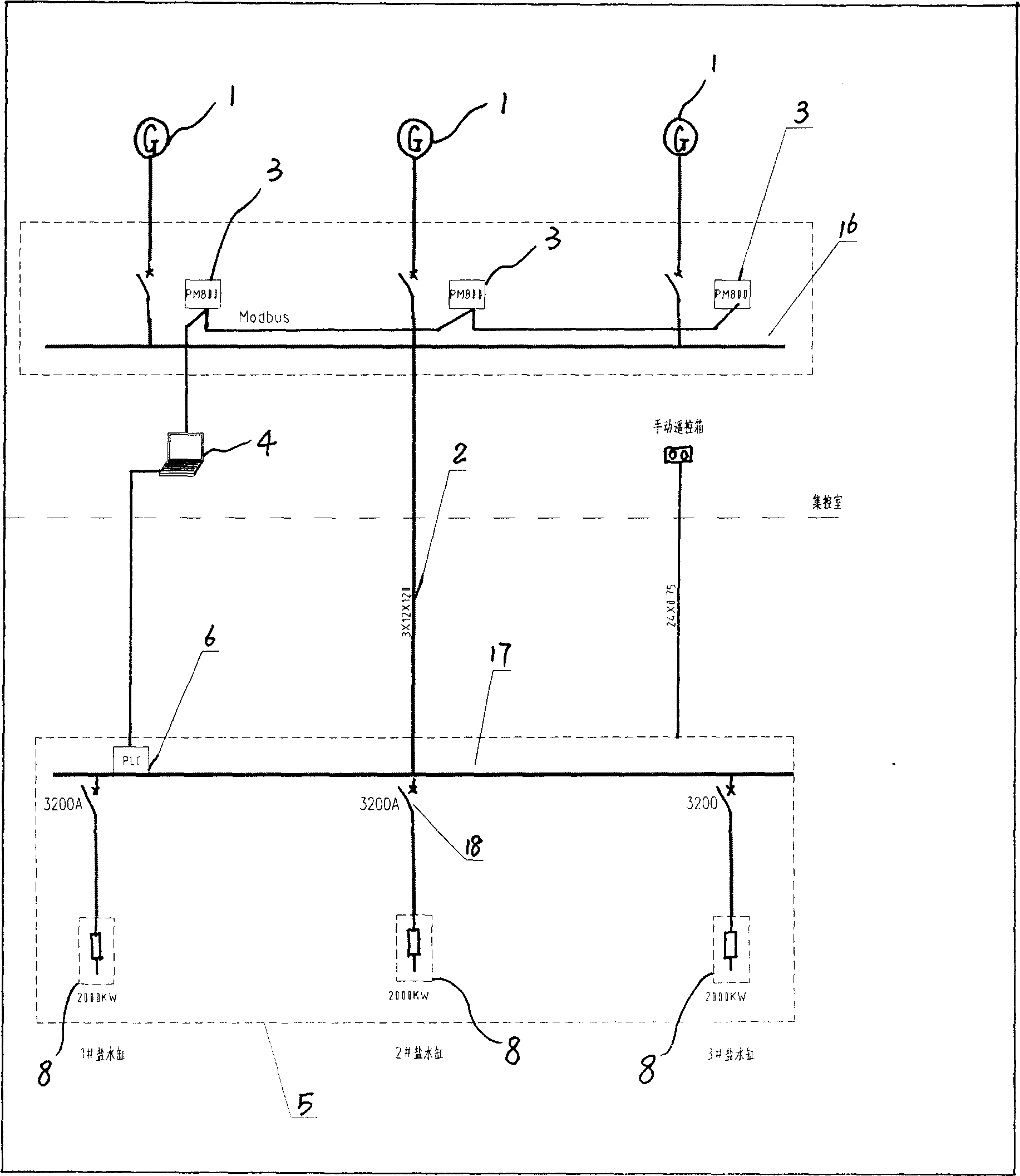

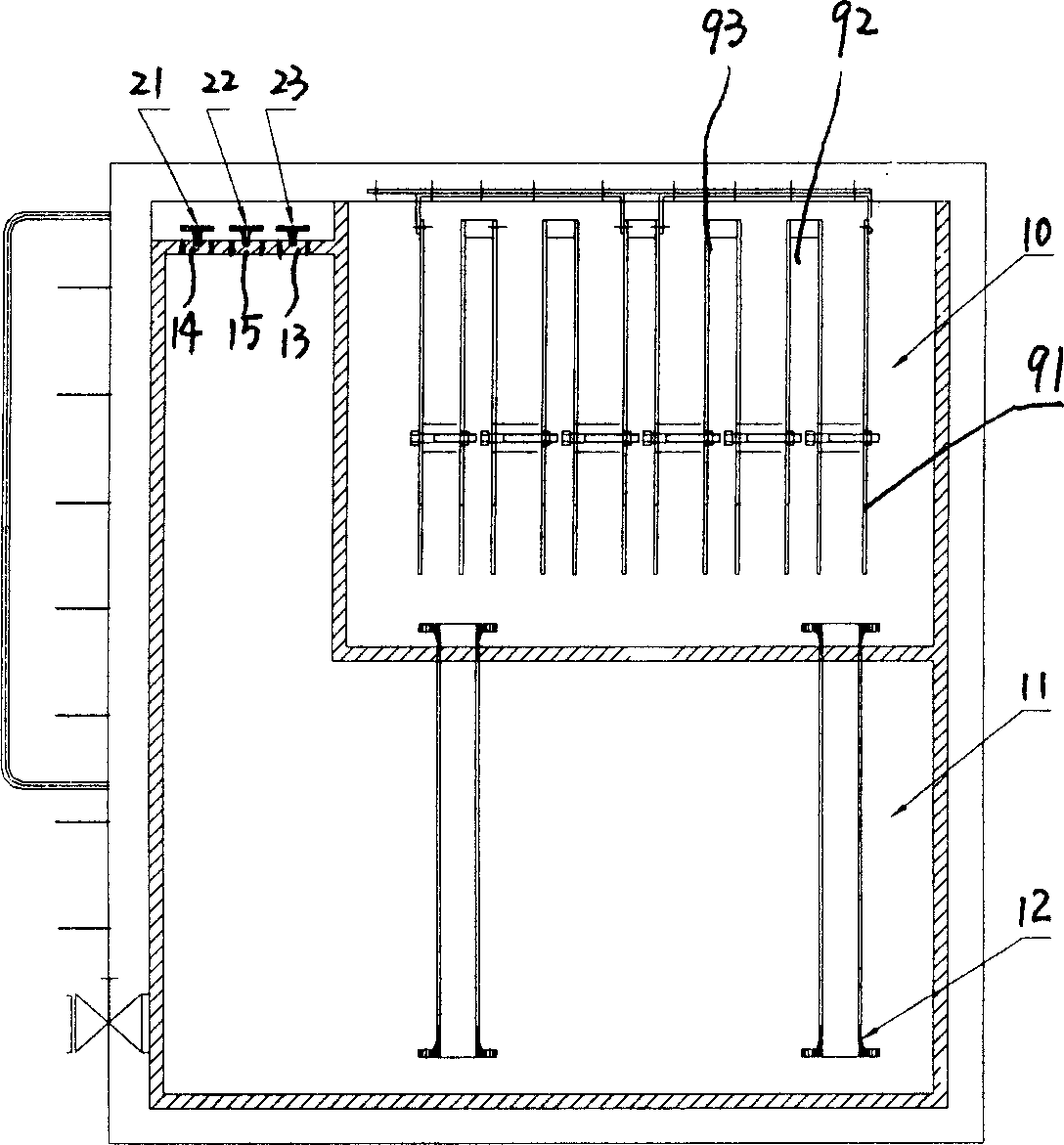

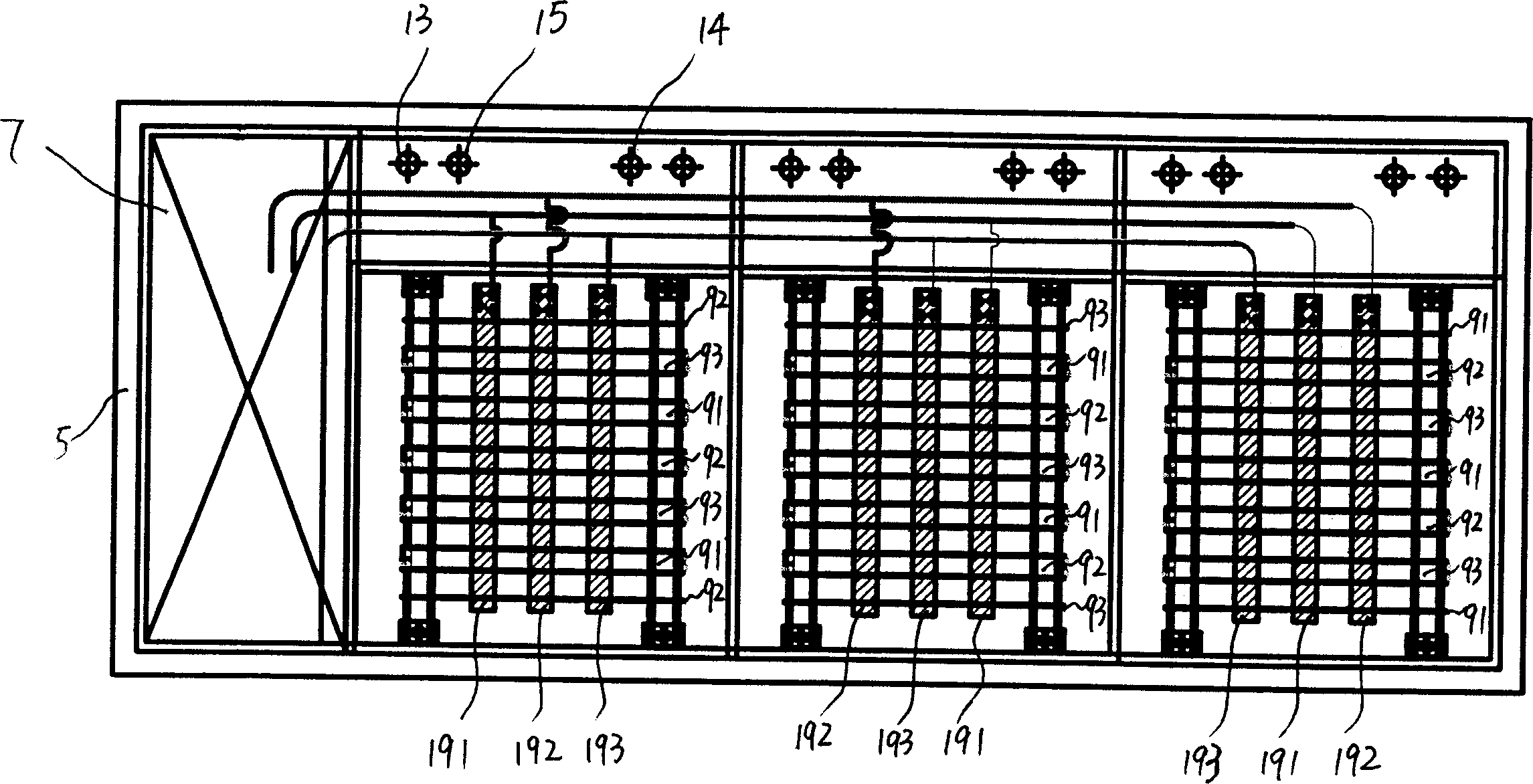

[0019] Such as Figure 1~3 As shown in the structure, the comprehensive test system for marine power station of the present invention includes a generator 1, an experimental load cable 2, a power parameter measuring instrument 3, a monitoring computer 4, a salt water tank group 5 composed of three salt water tanks, a programmable control device 6 and electrical control box 7, the power parameter measuring instrument 3 is connected to the ship power station, and its signal output terminal is connected with the signal input terminal of the monitoring computer 4 for measuring the real-time voltage, frequency, power and other parameters of the generator 1 On monitoring computer 4, configuration software is installed, and the real-time data collected by power parameter measuring instrument 3 is displayed and recorded in real time on computer screen by the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com