Drafting arrangement for a spinning machine

A technology for spinning machines and drafting equipment, applied in the field of automatic leveling and drawing frames, which can solve the problems of weakened running calm, asynchronous drafting equipment rollers, and interference that cannot be effectively eliminated, and achieves the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

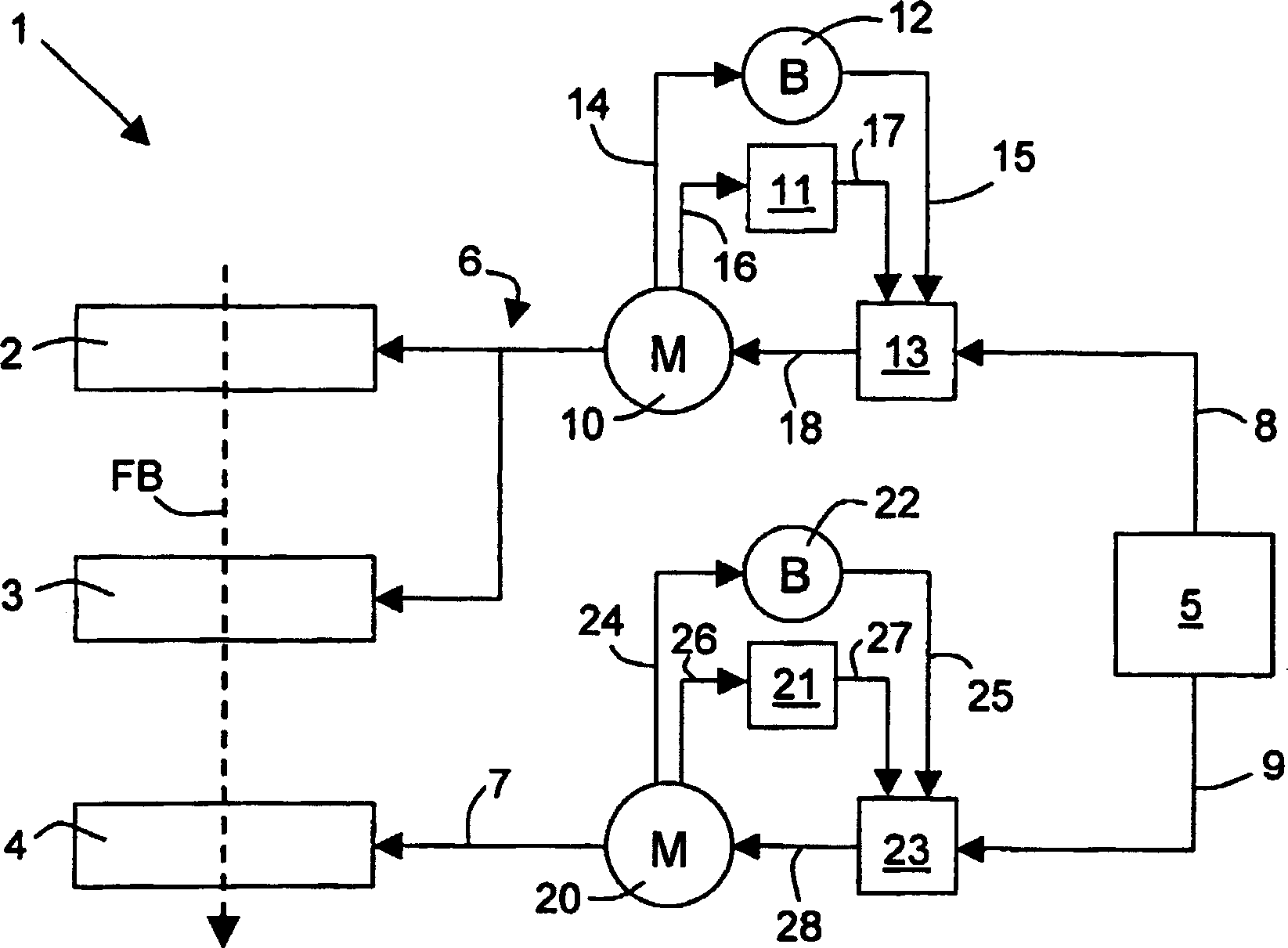

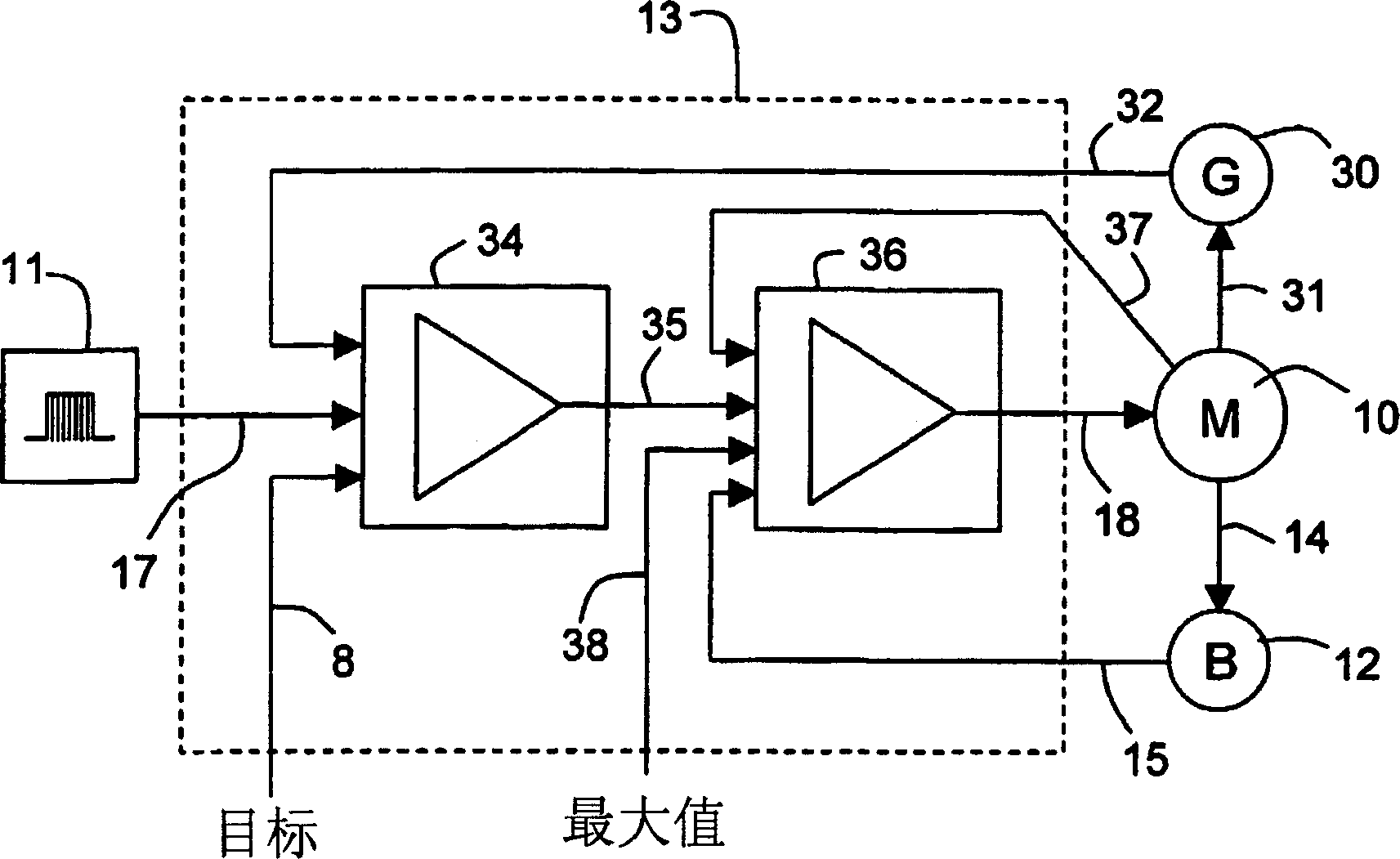

[0024] figure 1 An adjusted drafting device 1 according to the invention is shown schematically, comprising a pair of input rollers, a pair of intermediate rollers and a pair of output rollers. exist figure 1 Only the bottom rollers of these roller pairs are shown in , that is, input bottom roller 2, intermediate bottom roller 3 and output bottom roller 4. Only these bottom rollers 2, 3, 4 are driven, whereas top rollers, not shown, are pressed against the respective bottom rollers 2, 3, 4, so that the schematically directed fiber strip FB is clamped between the roller pairs. Both the bottom rollers 2, 3 are driven by a common electric motor 10, which produces a specified pre-draft via a transmission stage (not shown in more detail) with a belt drive 6 located between the input and intermediate roller pairs. stretch. The output bottom roller 4 is driven by a separate electric motor 20 via a belt drive 7 (not shown in more detail). The rpm of the electric motors 10, 20 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com