Light guide plate and backlight module assembly

A technology of backlight module and light guide plate, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of unfavorable light energy utilization rate, reflection and scattering loss, etc., and achieve the goal of improving light energy utilization rate and light energy utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

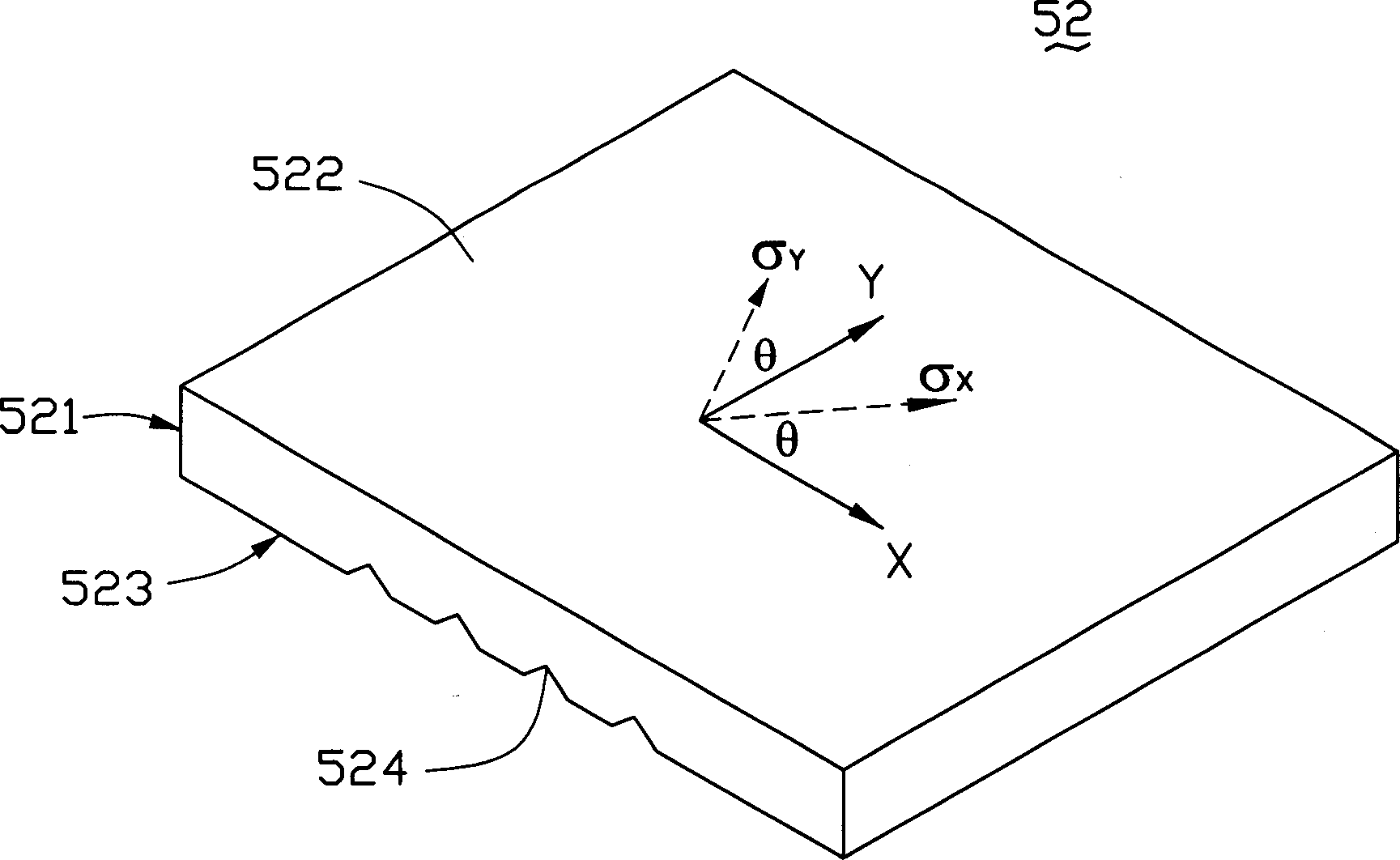

[0025] Such as image 3 As shown in FIG. 1 , is a perspective view of the light guide plate according to the first embodiment of the present invention. The light guide plate 52 is flat and includes a light incident surface 521 , a light exit surface 522 perpendicular to the light incident surface 521 , and a bottom surface 523 opposite to the light exit surface 522 . The bottom surface 523 of the light guide plate 52 is provided with microstructures 524 . In this embodiment, the light guide plate 52 is made of polycarbonate material, the microstructure 524 is a V-shaped groove, and the light emitting surface 522 is a plane.

[0026] The light guide plate 52 is a stress birefringent light guide plate made by applying stress or strain by utilizing the photoelastic effect. Such as image 3 As shown, first define the direction perpendicular to the light incident surface 521 of the light guide plate 52 as the X axis, and the direction perpendicular to the X axis and parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com