Compositions and processes for immersion lithography

A technology of immersion exposure and composition, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment for optomechanical equipment, and can solve the problems that immersion lithography systems do not exist widely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1: the preparation of particle additive

[0088] The preferred fluorinated particulate additive is prepared according to the following steps:

[0089] Add the required amount of propylene glycol monomethyl ether acetate (PGMEA) in the reaction vessel, 2 Heat to 80°C under purge. The following monomers (PFPA, ECPMA, TMPTA), crosslinker and initiator (tert-amyl peroxypivalate) were mixed into PGMEA in an 80-90% by weight liquid composition in an ice bath. The content of initiator accounts for 4% of the total weight of monomer and crosslinking agent. The amount of monomer used is as follows: 70% by weight of pentafluoroacrylate (PFPA), 20% by weight of ethylcyclopentyl methacrylate (ECPMA) and 10% by weight of (trimethylolpropane triacrylate) ( TMPTA):

[0090]

[0091] The monomer / crosslinker / initiator / PGMEA mixture was then added to the reaction vessel over 90 minutes. After the addition to the reaction vessel was complete, the mixture in the reaction ...

Embodiment 2

[0093] Embodiment 2: photoresist preparation and processing

[0094] A photoresist composition was prepared by mixing the following amounts of materials:

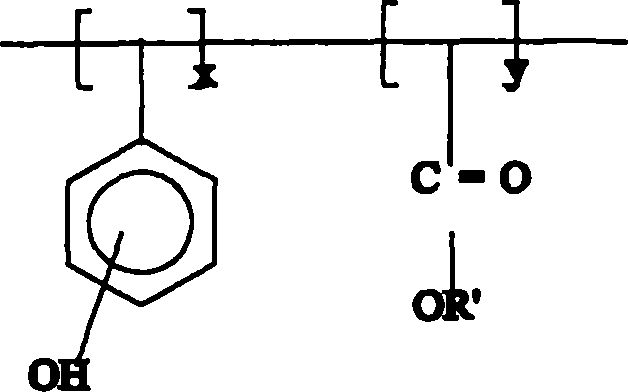

[0095] 1. Resin component: terpolymer of (2-methyl-2-adamantyl methacrylate / β-hydroxy-γ-butyrolactone methacrylate / cyano norbornyl methacrylate), Based on the total weight of the photoresist composition, its content is 6.79% by weight.

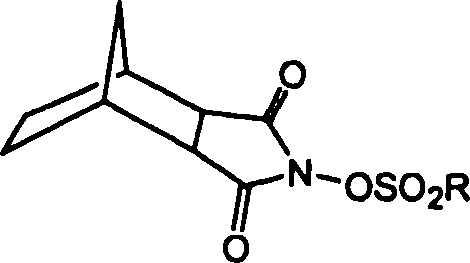

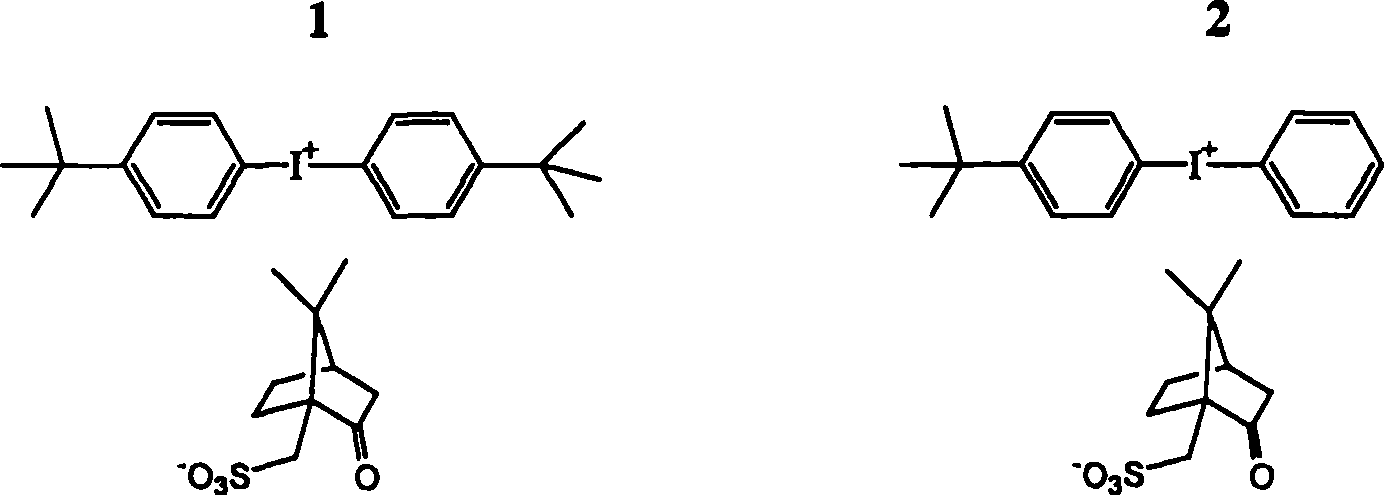

[0096] 2. Photoacid generator compound: tert-butylphenyltetramethylenesulfonium perfluorobutanesulfonate, based on the total weight of the photoresist composition, its content is 0.284% by weight.

[0097] 3. Alkali additive: N-alkylcaprolactam, based on the total weight of the photoresist composition, its content is 0.017% by weight.

[0098] 4. Surfactant: R08 (fluorine-containing surfactant, purchased from Dainippon Ink & Chemicals, Inc.), based on the total weight of the photoresist composition, its content is 0.0071% by weight.

[0099] 5. Additives that cannot be mixed substantiall...

Embodiment 3

[0105] Example 3: Photoresist Preparation and Treatment.

[0106] A photoresist composition was prepared by mixing the following amounts of materials:

[0107] 1. Resin component: terpolymer of (2-methyl-2-adamantyl methacrylate / β-hydroxy-γ-butyrolactone methacrylate / cyano norbornyl methacrylate), Based on the total weight of the photoresist composition, its content is 6.79% by weight;

[0108] 2. Photoacid generator compound: tert-butylphenyltetramethylenesulfonium perfluorobutanesulfonate, based on the total weight of the photoresist composition, its content is 0.284% by weight.

[0109] 3. Alkali additive: N-alkylcaprolactam, based on the total weight of the photoresist composition, its content is 0.017% by weight.

[0110] 4. Surfactant: R08 (fluorine-containing surfactant, purchased from Dainippon Ink & Chemicals, Inc.), based on the total weight of the photoresist composition, its content is 0.0071% by weight.

[0111] 5. Essentially immiscible additives: Isooctyl pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com