Single-phase blushless motor

A brushless motor, single-phase technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problem of torque ripple reduction, to achieve the reduction of phase difference suppression, vibration and noise suppression, vibration and noise suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

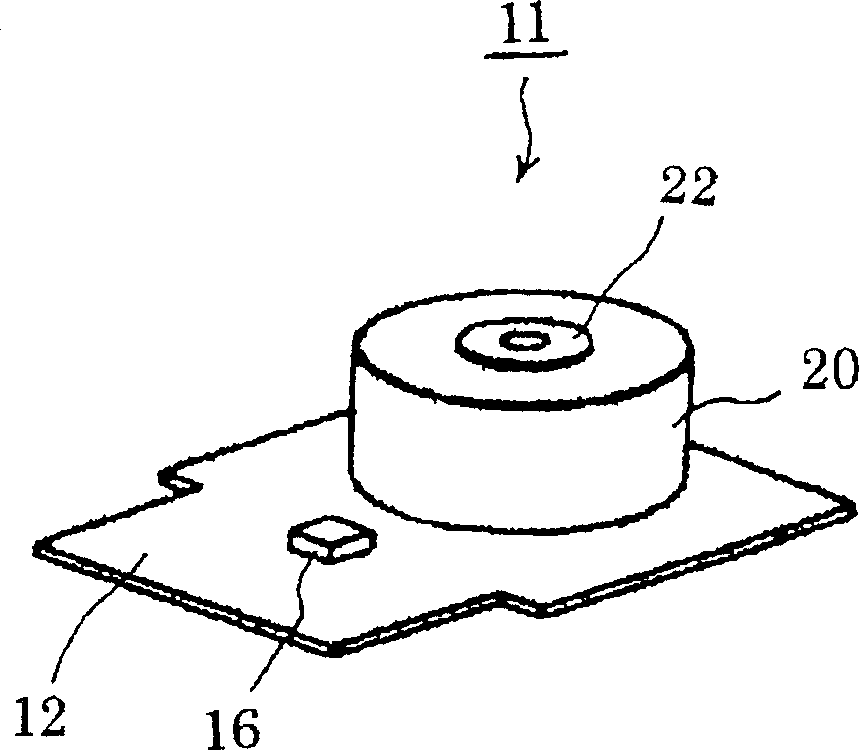

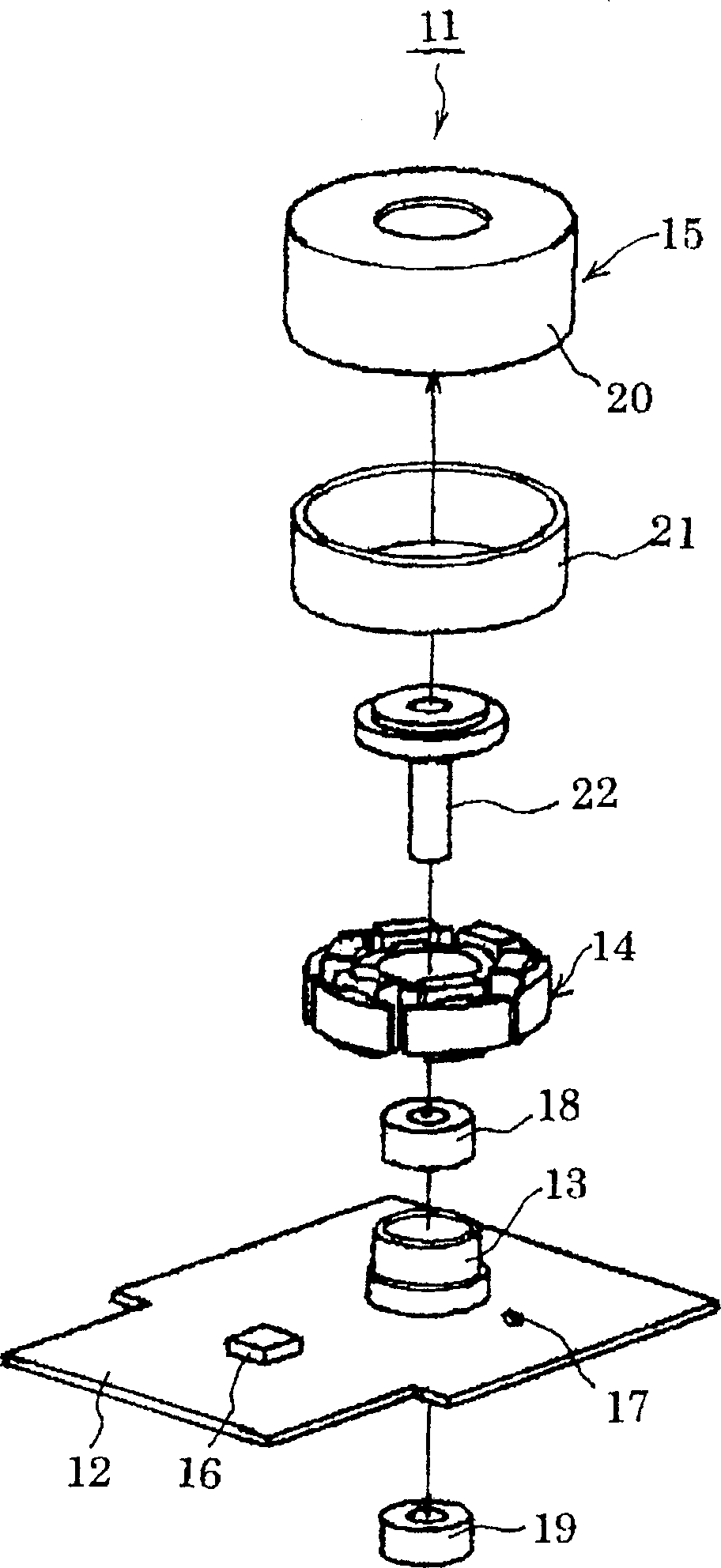

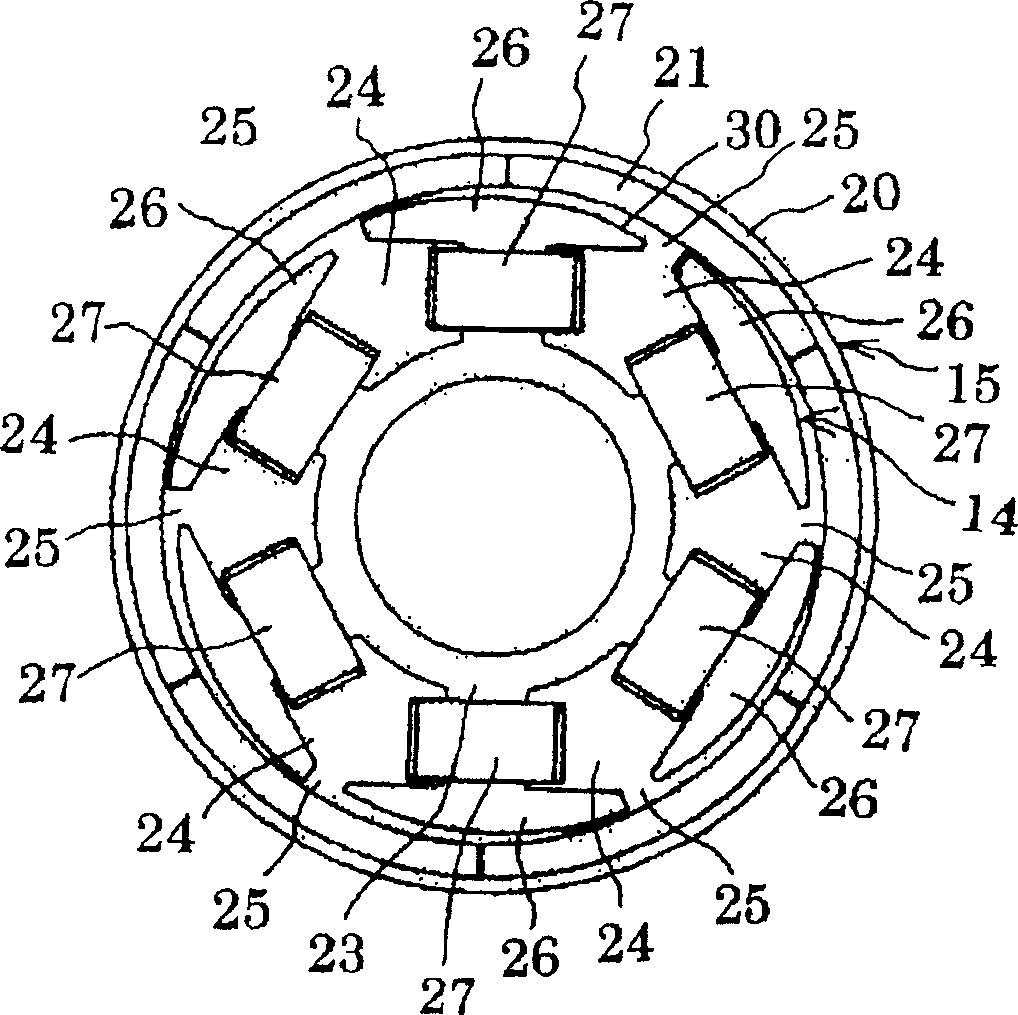

[0059] figure 1 is an external view of a single-phase brushless motor shown as the first embodiment of the present invention, figure 2 yes figure 1 An exploded perspective view of the single-phase brushless motor shown. Figure 3-Figure 5 Indicates the details of its various parts. In addition, although the illustrated form is applied to an outer rotor type brushless motor for air cooling of electronic equipment, the present invention is of course not limited thereto.

[0060] figure 1 and figure 2 The illustrated single-phase brushless motor 11 has an outer rotor shape, and is a single-phase brushless motor having a shape of 6 magnetic poles and 6 salient poles. The single-phase brushless motor 11 includes a stator 14 attached to a housing 13 fixed via a base plate 12 on the device (not shown) side, and a rotor 15 driven to rotate with respect to the stator 14 . In addition, on the substrate 12 are mounted a driver IC 16 incorporating a circuit for driving the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com