Negative pressure type booster device

一种助力器、负压式的技术,应用在负压式助力器装置领域,能够解决节流噪音泄漏等问题,达到平稳操作、结构紧凑、抑制噪音的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

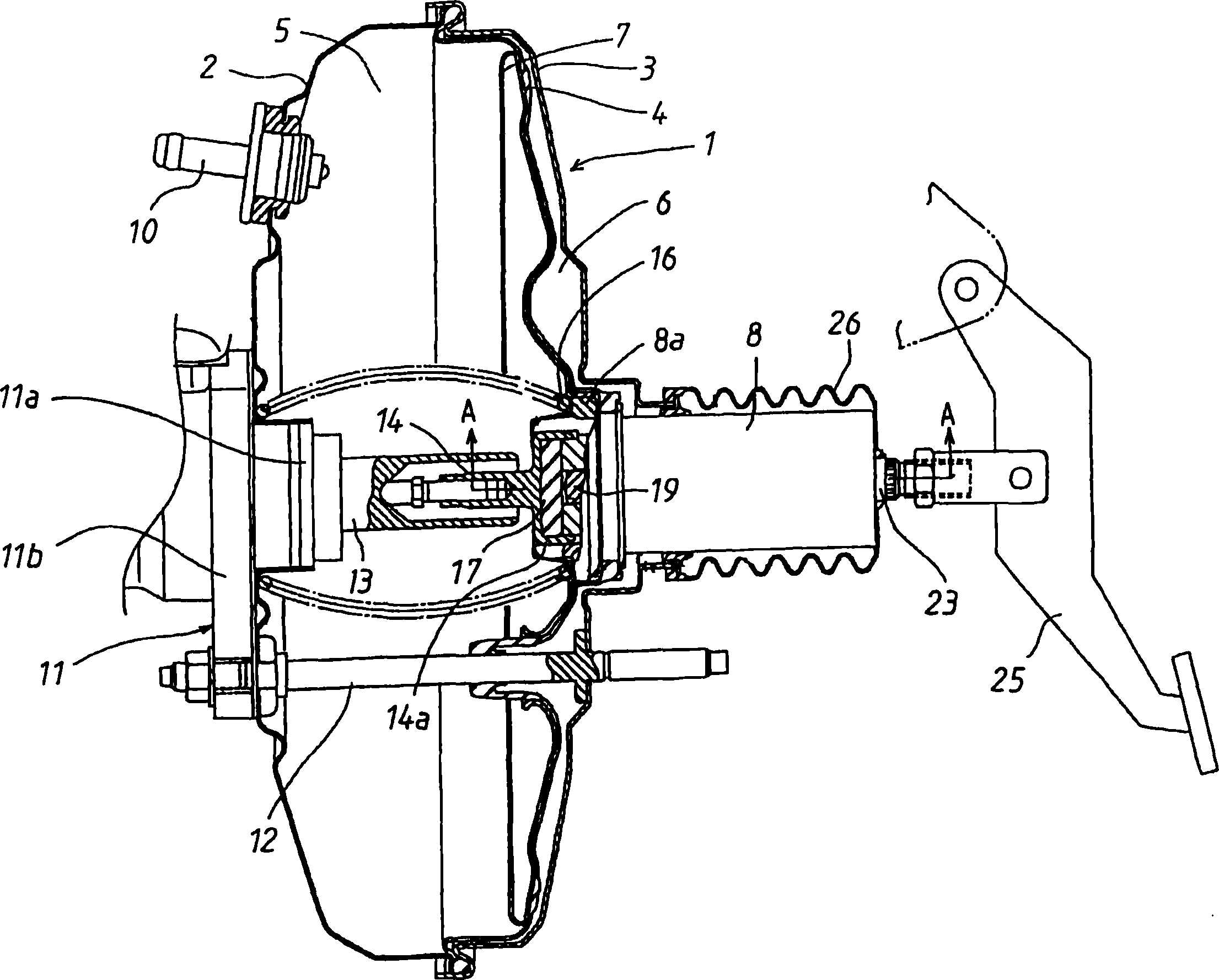

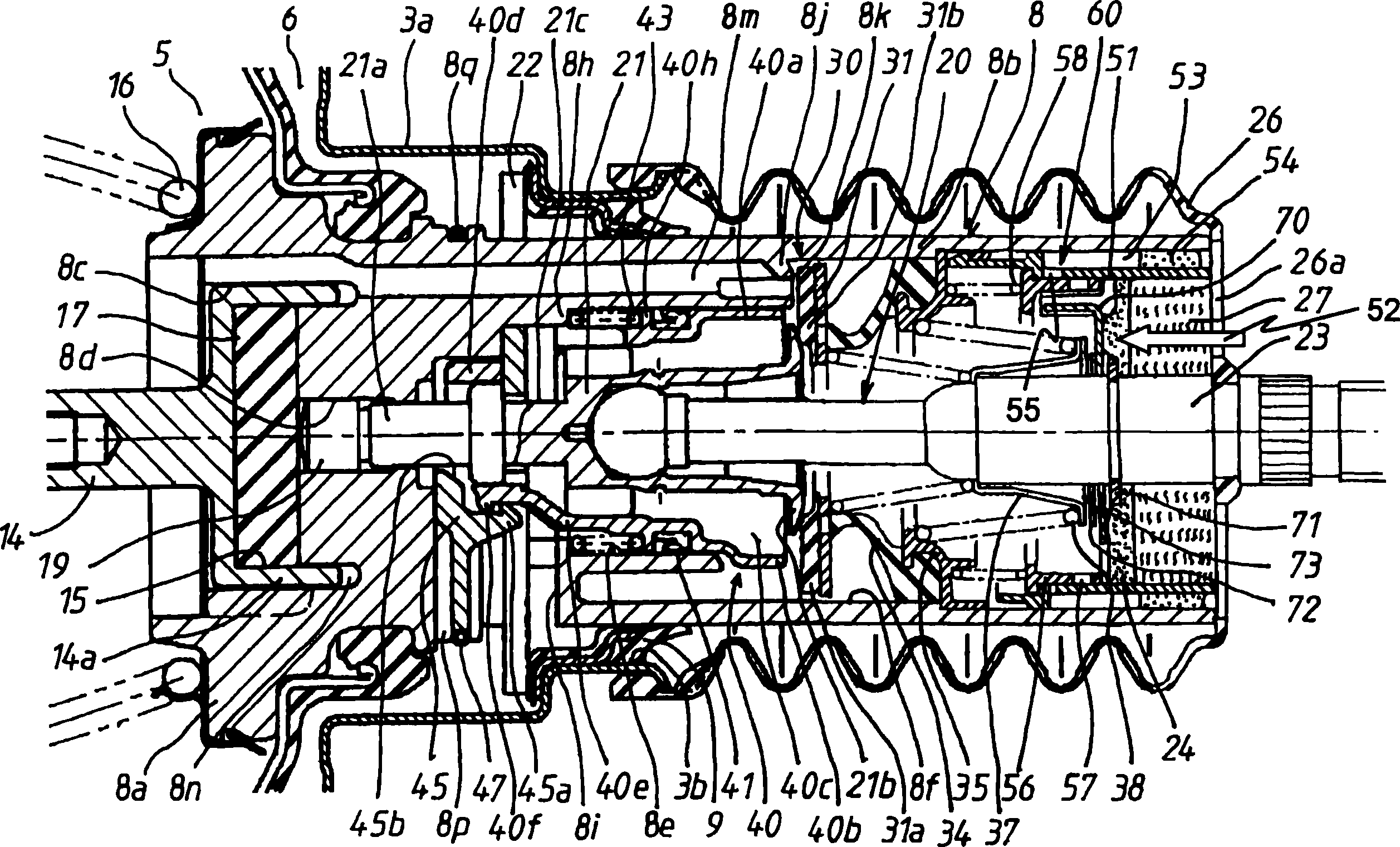

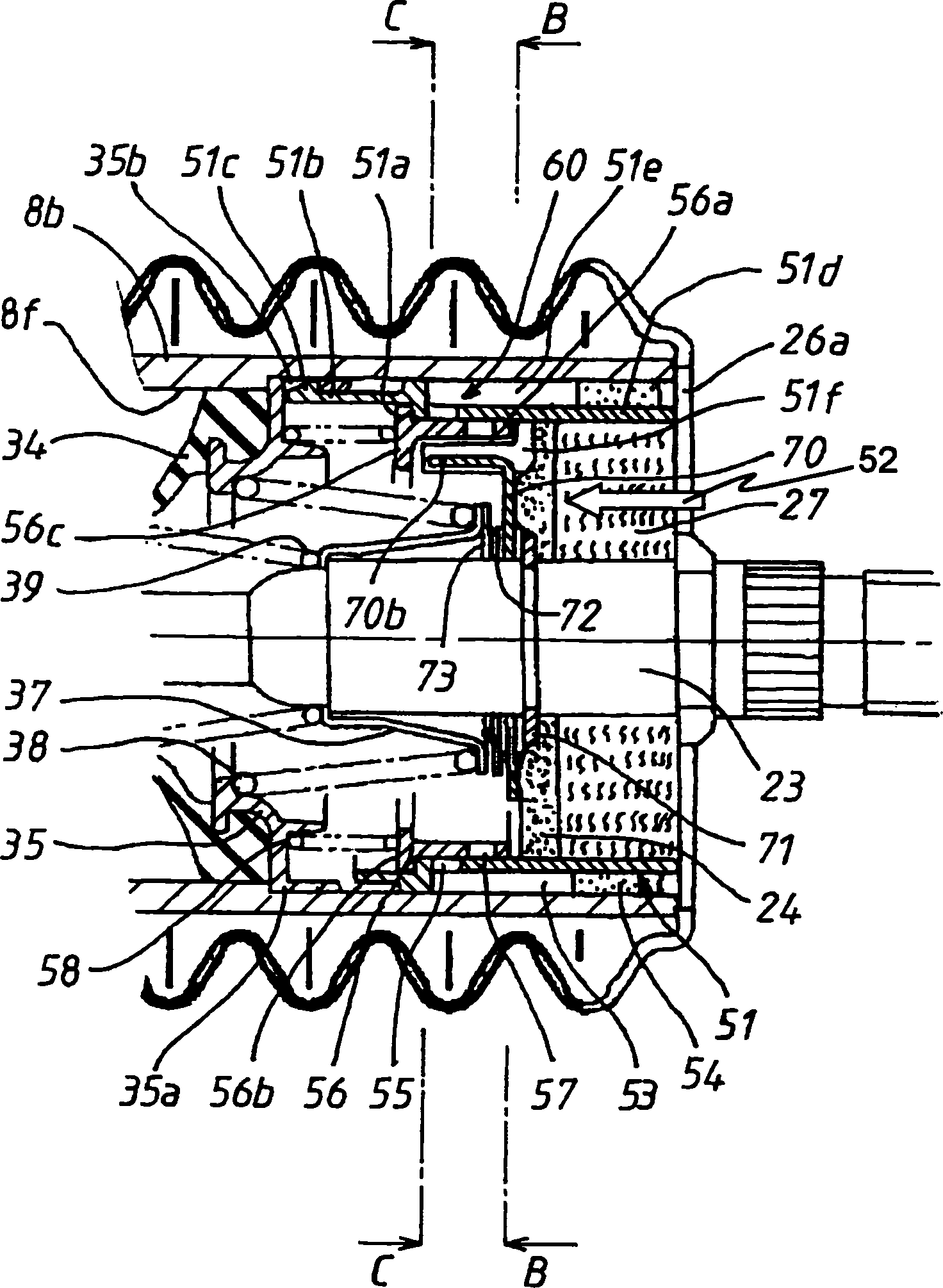

[0038] Hereinafter, a negative pressure booster device according to an embodiment of the present invention will be described with reference to the accompanying drawings. now refer to figure 1 , The booster housing 1 is composed of a front housing 2 and a rear housing 3 . Between the two housings 2 and 3, a flexible diaphragm 4 serving as a partition member is airtightly fixed at its peripheral rim portion, and divides the interior of the booster housing 1 into a constant pressure chamber 5 and a variable pressure chamber. pressure chamber6. The disc plate 7 is laminated on the diaphragm 4 inside the constant pressure chamber 5 . The valve piston 8 is airtightly fixed on the diaphragm 4 and the plate 7 at the outer surface of its base 8 a with the front end surface of the base 8 a exposed to the constant pressure chamber 5 . The negative pressure guide conduit 10 is attached on the front housing 2, and the constant pressure chamber 5 communicates with the intake manifold of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com