W type gravity flow automatic control highly effective methane tank

A biogas digester and high-efficiency technology, which is applied in the direction of gas production bioreactor, waste fuel, etc., can solve the problems of not solving dead zone, crusting, occupying the volume of fermentation tank, reducing the utilization rate of material and liquid, etc., and achieves a convenient factory scale. The effect of improving production and gas production efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

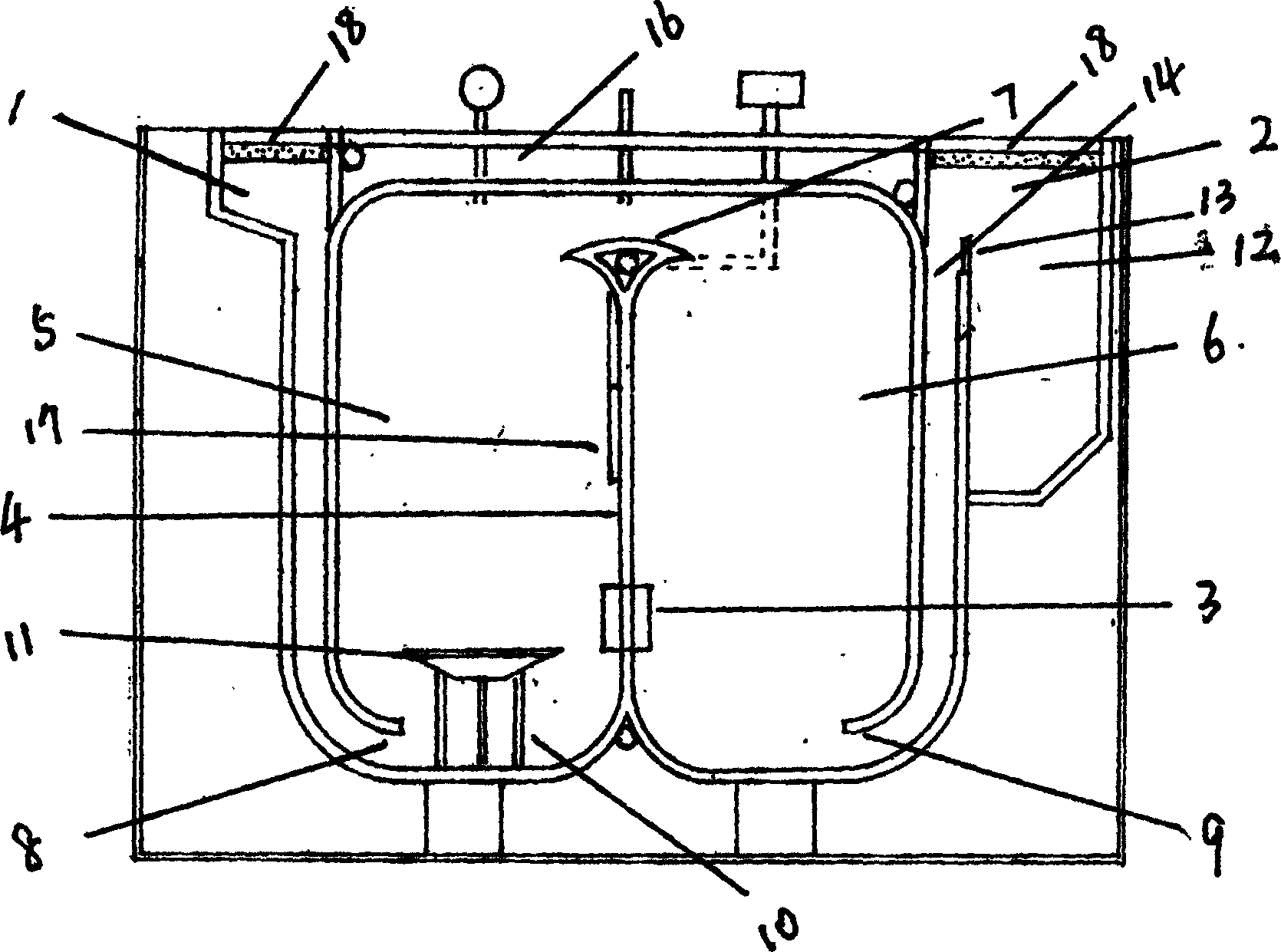

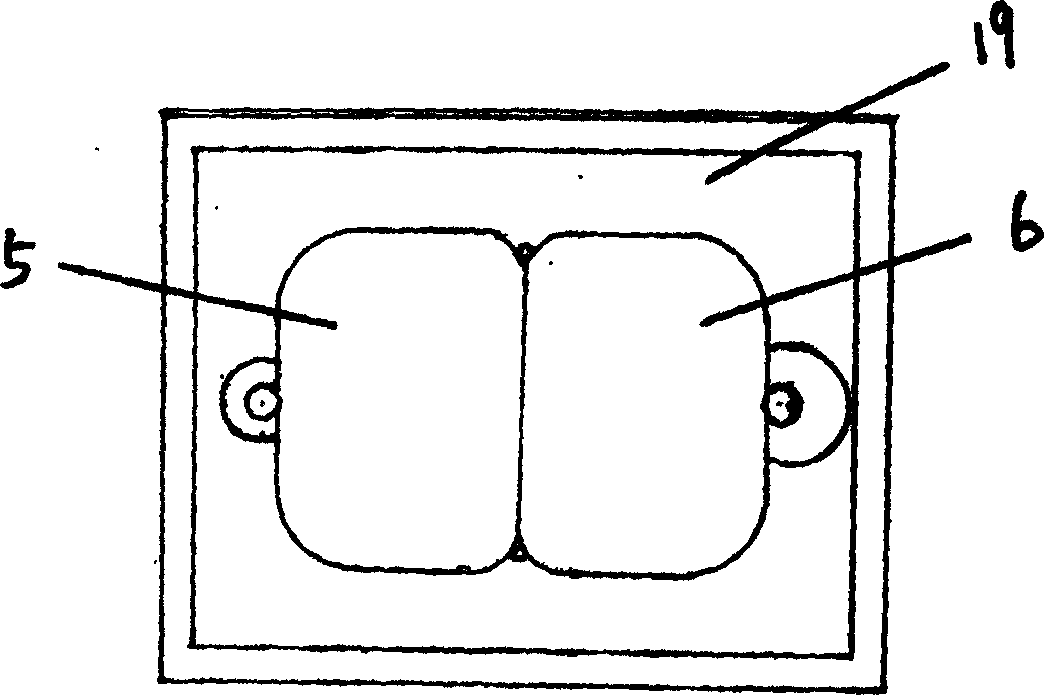

[0019] Below in conjunction with accompanying drawing and specific example the present invention will be further described:

[0020] First, use unsaturated polymer resin, plexiglass steel as the sealed waterproof inner lining, and use magnesium oxide, magnesium chloride, inorganic glass steel and glass fiber cloth as a strong shell, and use glue to compound the fermentation tank body.

[0021] Open the feed port sterilization cover 18, the sterilization cover 18 is attached with a sponge body and can inject the sterilizing liquid, which can slow release and sterilize to avoid odor and breed and spread germs. The feed liquid is injected into the feed inlet 1, and after being filtered by the filter, the large feed is filtered out and reprocessed before being injected. The material ring 10 evenly disperses the material liquid and then goes upward to ferment. On the top of the partition wall 4, an equalizing table 7 is set. The bottom of the even material table 7 is arc-shaped. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com