Layered steam distribution system for steam flooding and steam distribution method thereof

A technology of steam drive and steam distribution, which is applied in general control systems, control/regulation systems, earthwork drilling and production, etc., and can solve the problems that simultaneous steam drive cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

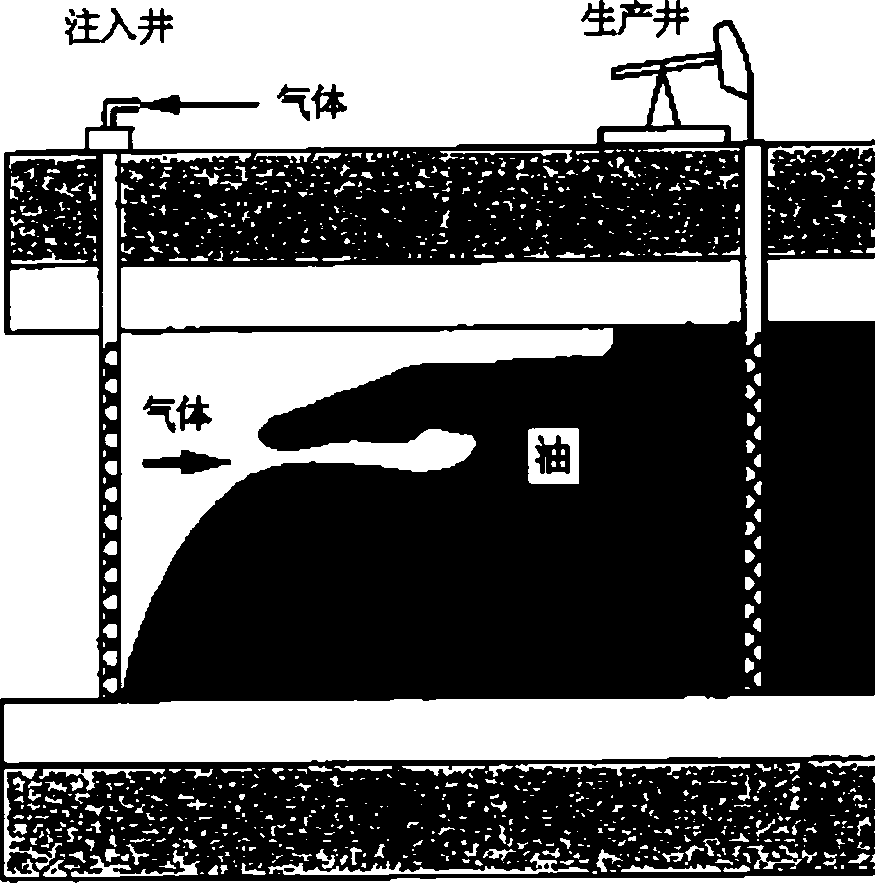

[0158] figure 1 It is a schematic diagram of the principle of downhole steam injection in the prior art.

[0159] figure 1 What is shown is the phenomenon of monolayer intrusion caused by steam overburden in the steam injection well. At present, the steam stimulation method has become the main technology for heavy oil development. However, most of the heavy oil reservoirs and blocks that have been put into steam huff and puff development in my country have entered the middle and late stages, that is, the steam huff and puff cycle is more than 5 weeks. Even if there are many oil reservoirs or blocks to drill infill wells and continue steam huff and puff production, the extended production period is limited. After multiple rounds of steam huff and puff, it is necessary to switch to the steam flooding production method in order to effectively improve the recovery rate. In recent years, the test results of more than ten steam flooding pilot projects developed through various t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com