Engine testing system and testing method thereof

A test system and engine technology, which is applied in the direction of engine test, machine/structural component test, measuring device, etc., can solve the problems of high test cost and low test efficiency, and achieve the effect of low test noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

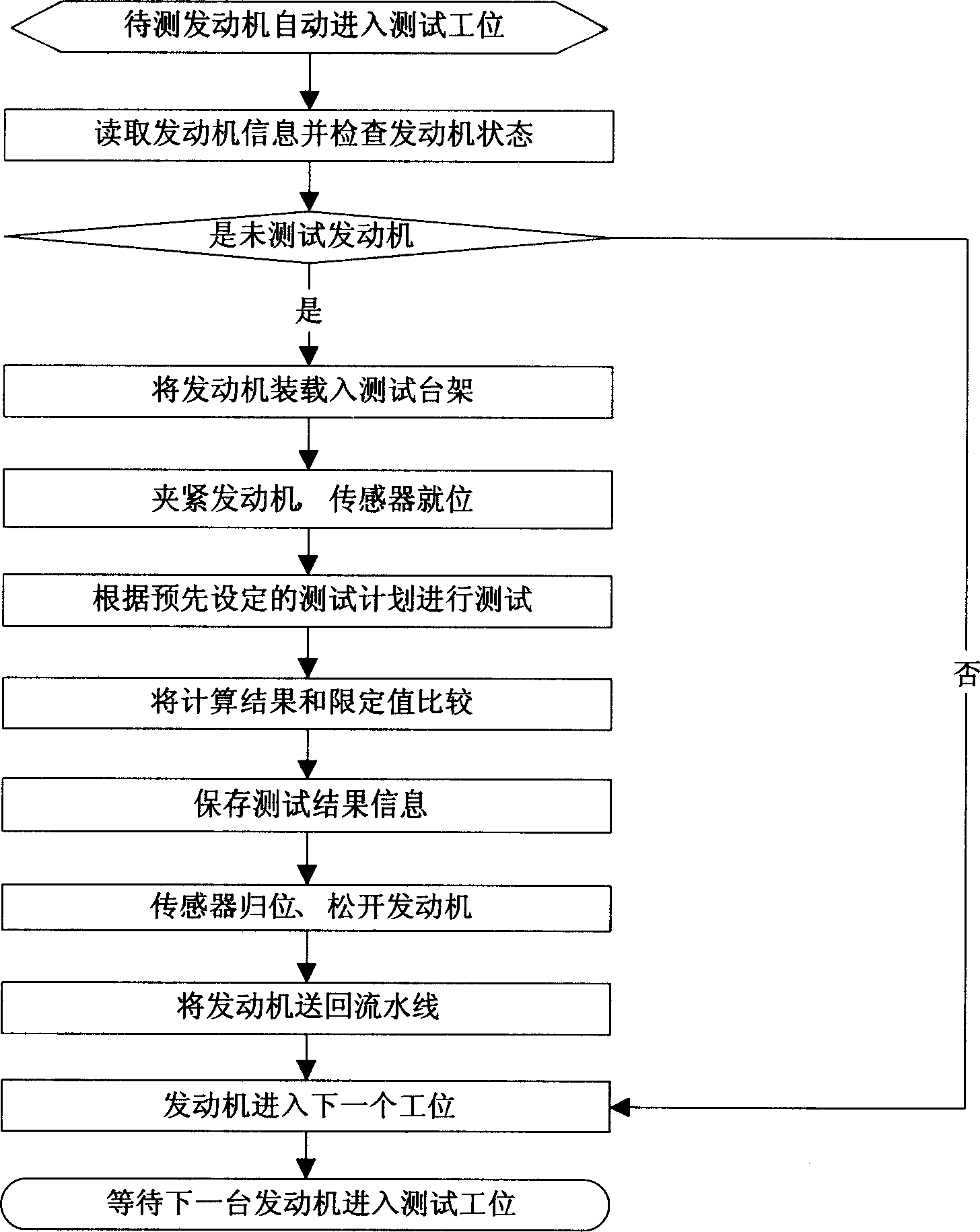

[0017] The engine testing system of the invention is a product testing system used at the end of the engine assembly line, used for testing whether the assembled engine is qualified and providing maintenance information for unqualified engines.

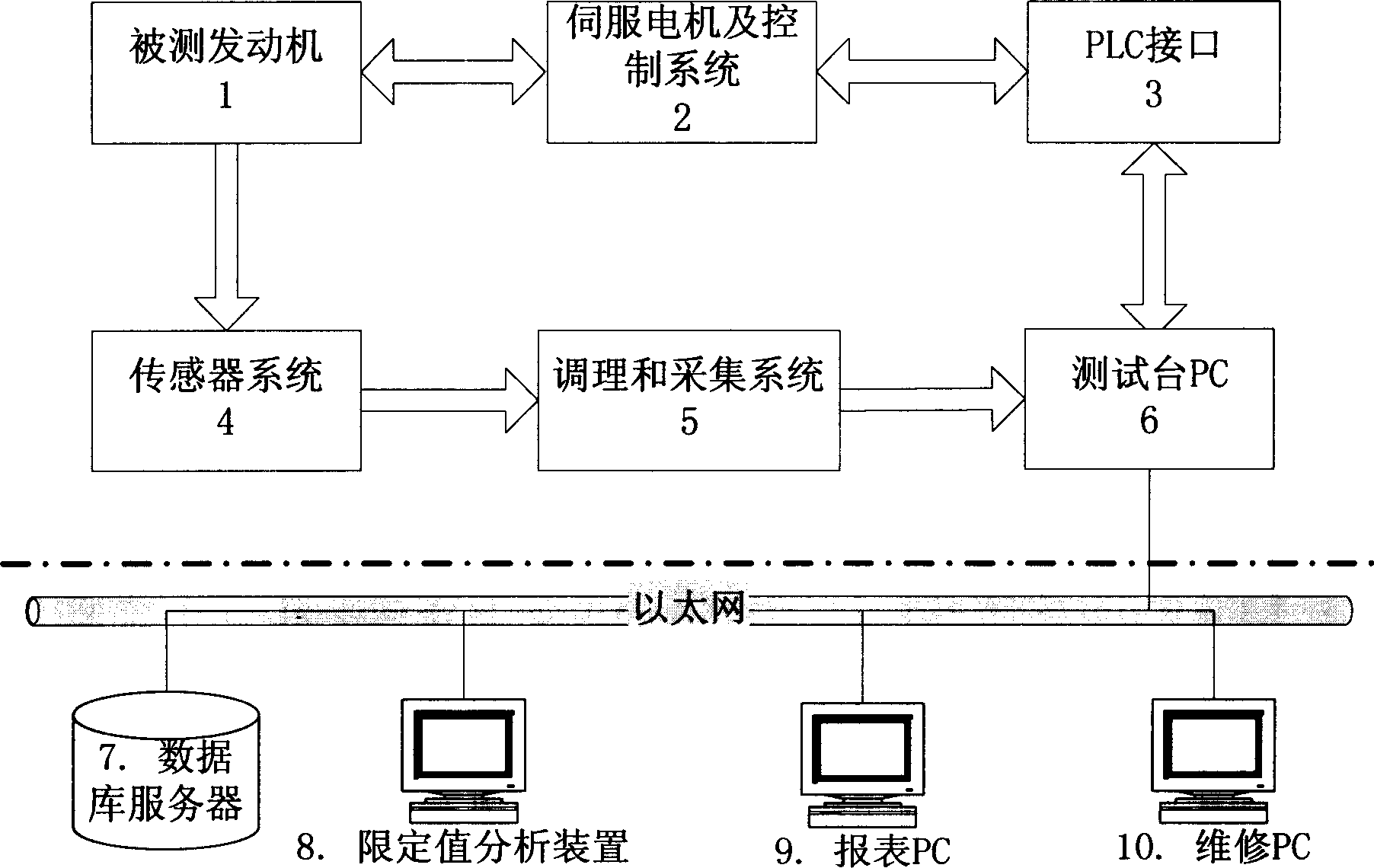

[0018] like figure 1 As shown, the engine test system of the present invention is composed of two parts: a test bench and an off-line data analysis device. The test bench is composed of servo motor and control system 2, PLC interface 3, sensor system 4, conditioning and acquisition interface 5, and test computer 6. In order to carry out automated testing, the test bench also includes fixtures, positioning devices, engine loading mechanisms, etc. (not shown in the figure).

[0019] The off-line analysis device is composed of a database server 7 , a limit value analysis device 8 , a report PC 9 and a maintenance PC 10 .

[0020] The DC servo motor in the servo motor and control system 2 is connected with the flywheel of the engine und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com