Spindle combine structure for gear compressor

A compressor and gear type technology, applied in the field of shaft combination structure of gear type compressors, can solve the problems of difficult component processing and assembly, shortened component life, power loss, etc. The effect of assembly tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the shaft coupling structure of the gear chamber compressor according to the present invention will be described in detail with reference to the accompanying drawings.

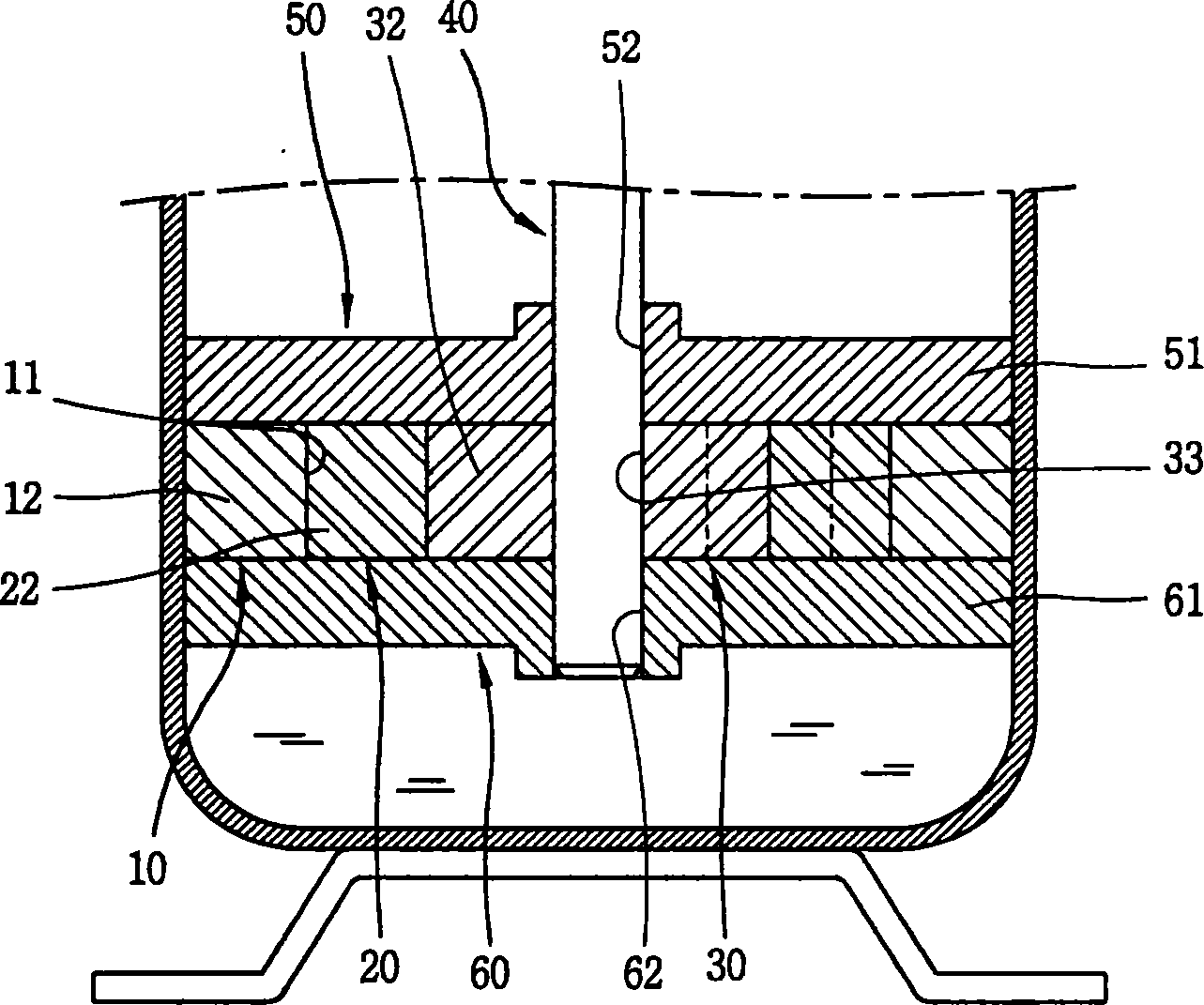

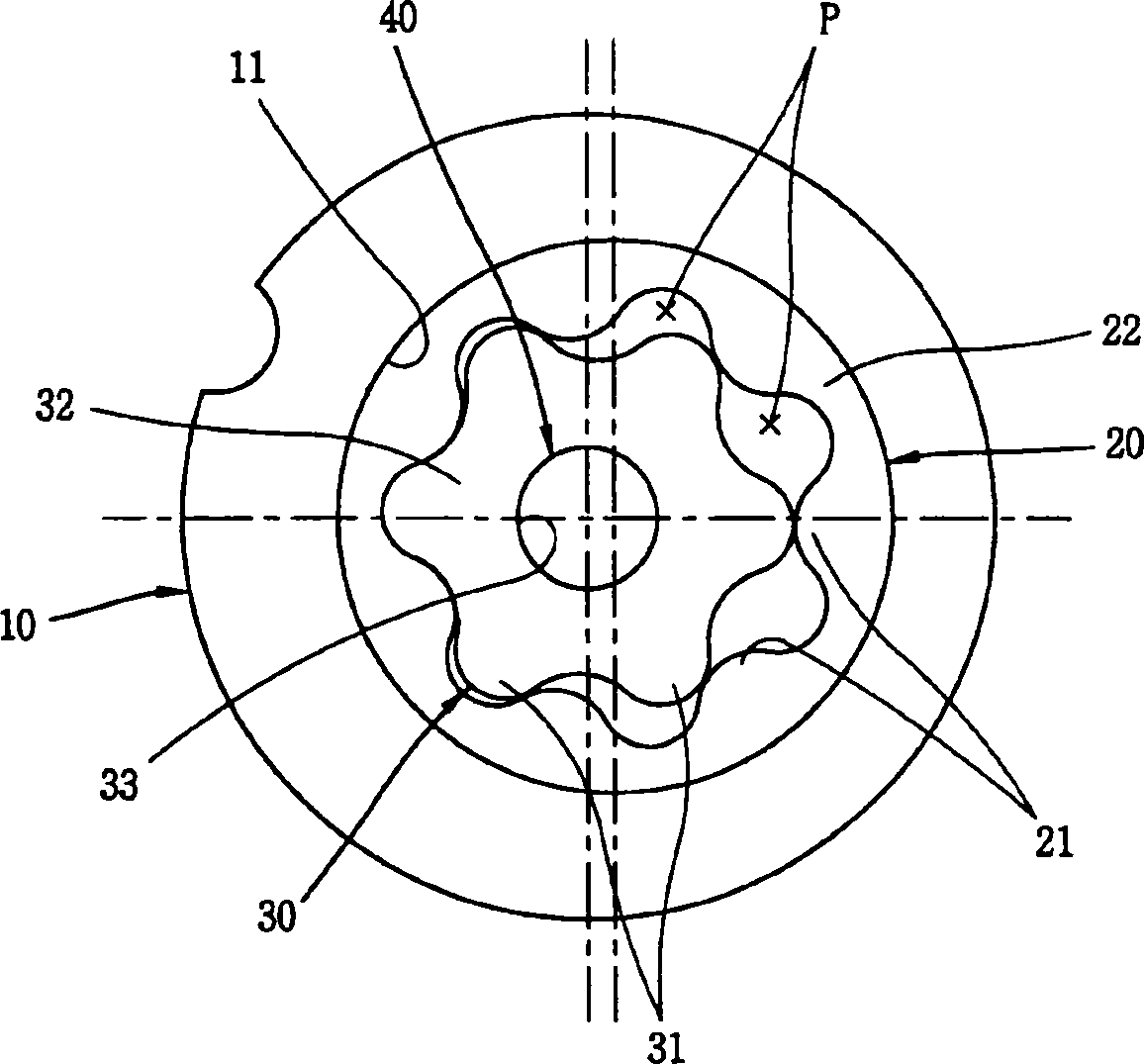

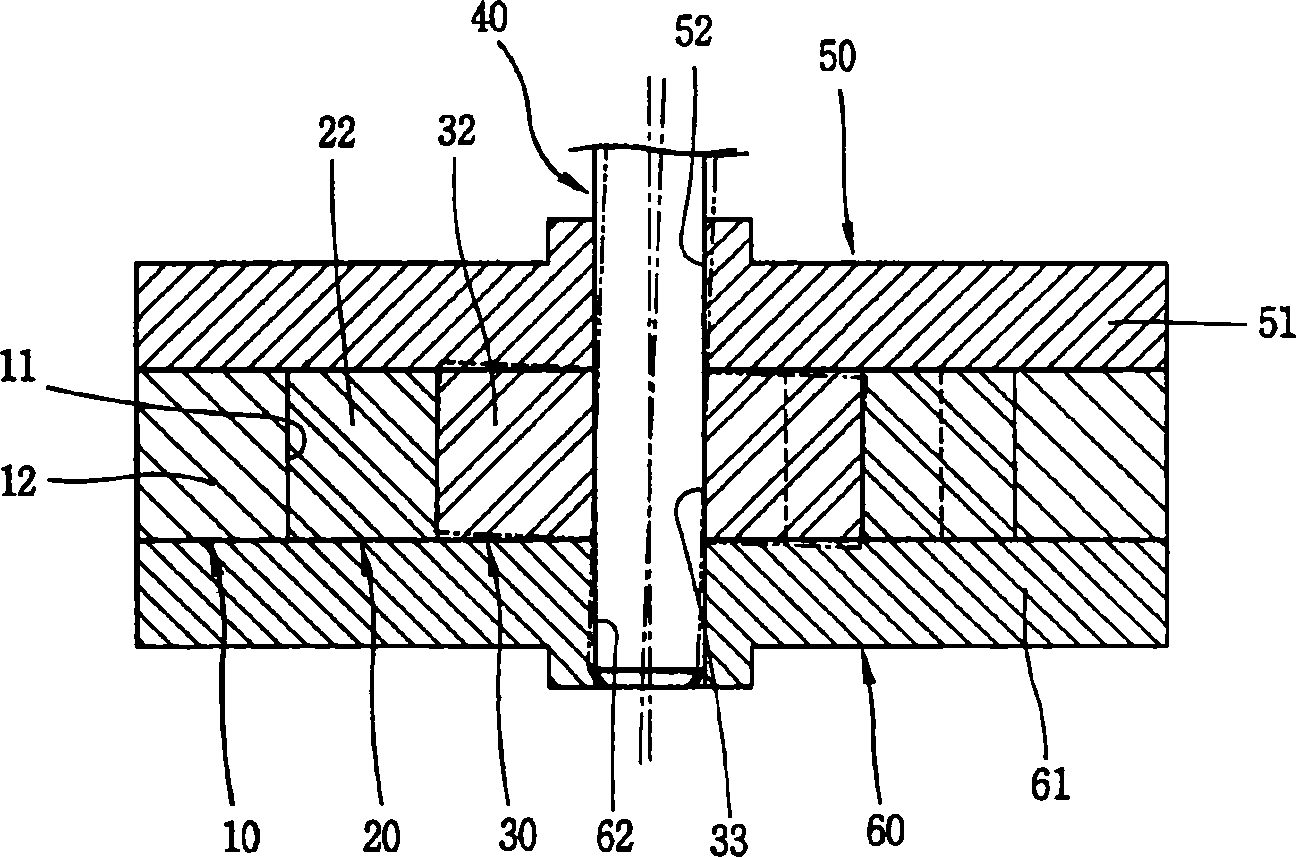

[0040] Figure 4 , 5 It is a front sectional view and a plan view of a compression part of a gear compressor having an embodiment of the gear compressor shaft coupling structure of the present invention.

[0041] As shown in the figure, firstly, the compression part of the above-mentioned gear compressor includes: a cylinder 10 with a gear insertion hole 11 formed inside it; Inserted into the gear insertion hole 11 of the above-mentioned cylinder 10; the inner gear 30, which has a plurality of gear teeth formed on its outer peripheral surface, is rotatably inserted into the above-mentioned outer gear 20 to form a plurality of compression spaces P together with the gear teeth 21 of the above-mentioned outer gear 20 The rotating shaft 40 is inserted and combined with the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com