Squirrel-cage electromagnetic retarder

A retarder and squirrel-cage technology, which is applied in the field of squirrel-cage electromagnetic retarders, can solve the problems of power consumption defects, vehicle power can not meet the needs of use, bulky and other problems, and achieve the best braking efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

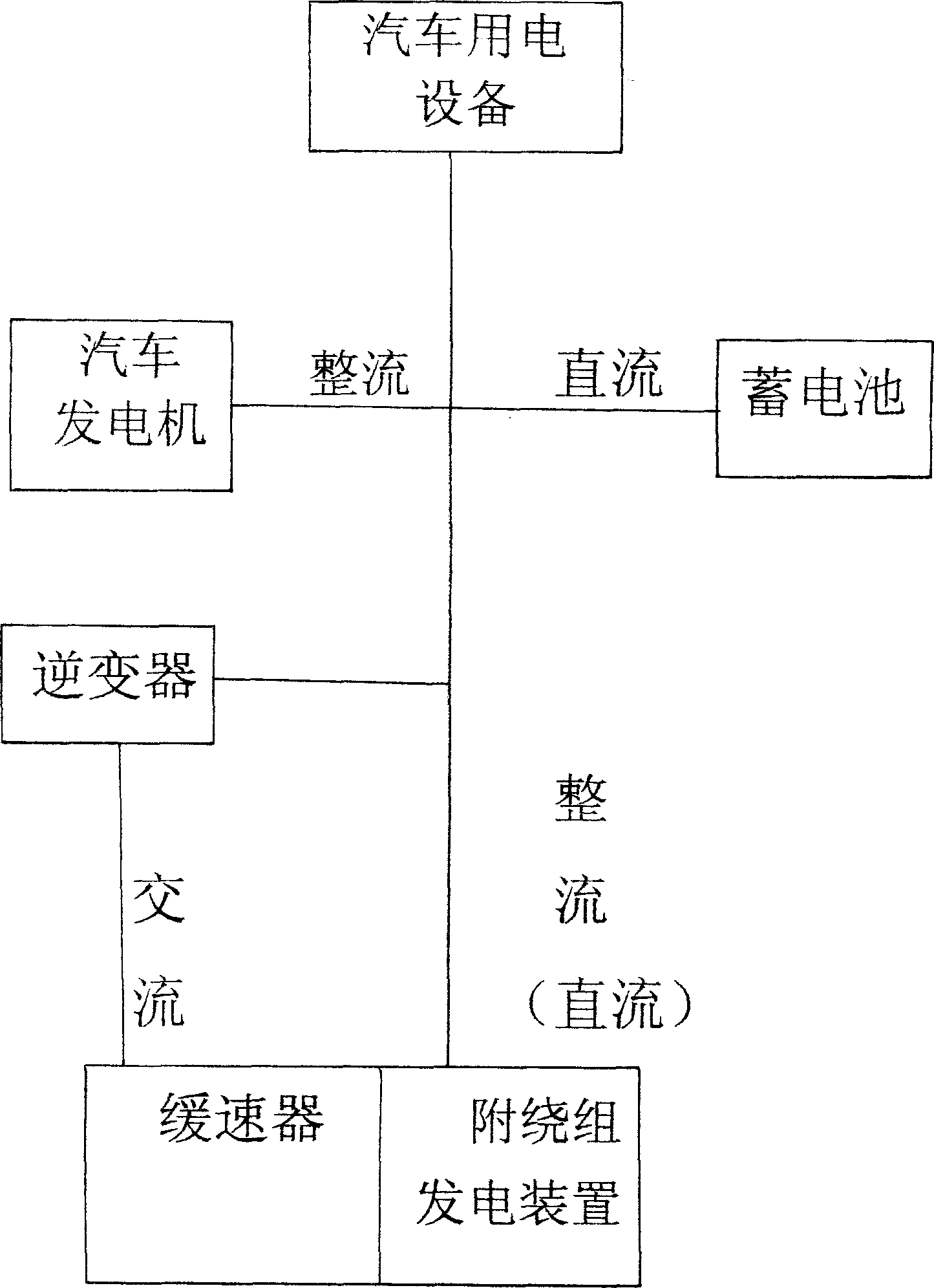

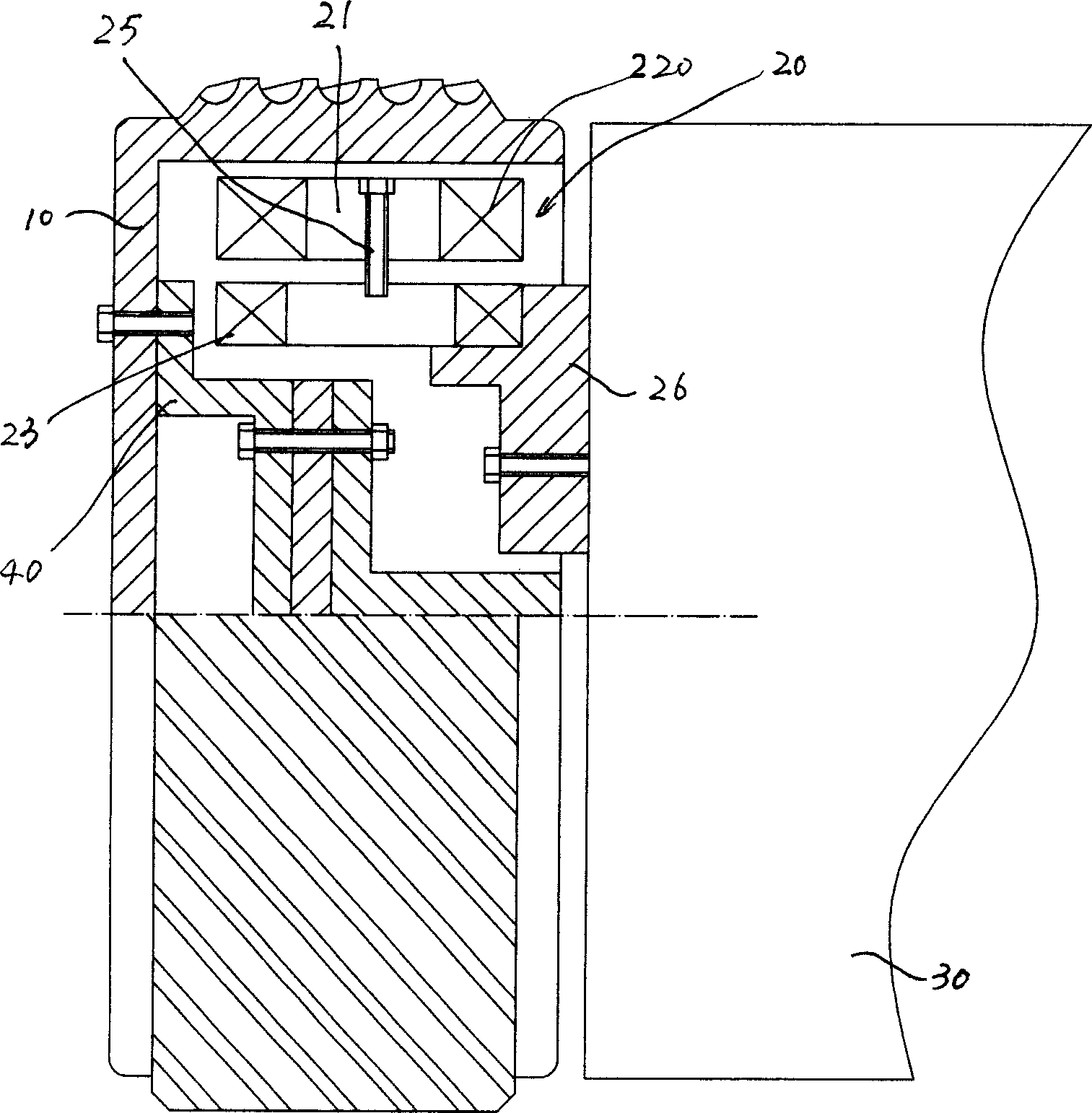

[0012] Such as figure 1 , 2 As shown, the squirrel-cage electromagnetic retarder of the present invention includes a rotor 10 and a stator 20, and the stator 20 includes a coil 22 arranged on a silicon steel sheet magnetic core 21, and a silicon steel sheet magnetic core 21 is also provided with The coil is attached to the winding 23, and the alternating current generated by the coil attached to the winding 23 is output to the consumer and the storage battery through the rectifier circuit.

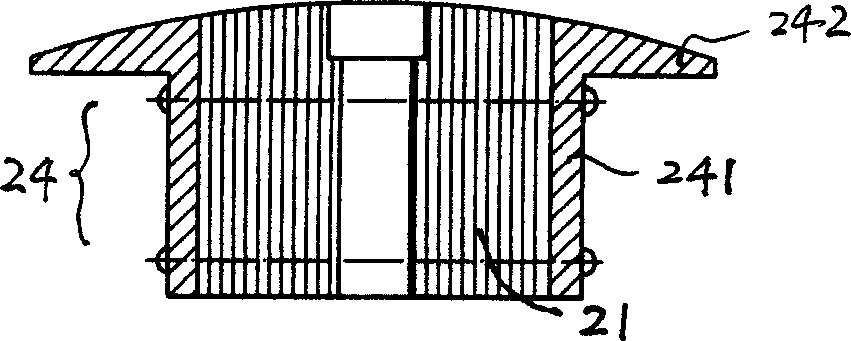

[0013] Such as image 3 , 4 , 5, the silicon steel sheet magnetic core 21 is located between the webs 241 of the frame plate steel 24, and the outer end of the frame plate steel 24 has wing plates 242 extending along both sides, and the silicon steel sheet magnetic core The middle part of the core 21 has radially arranged bolts 25 passing through and its inner end is connected with the coil attached winding 23 .

[0014] The webs 241 of the frame steel 24 on both sides are connected an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com