Method and device for operating an OLED device

An organic light-emitting element and organic technology, applied in the field of organic light-emitting diodes and operating organic light-emitting elements, can solve the problems of influence, color shift, limit the overall life of white OLED, etc., to shorten the pulse length, reduce differential aging, and lengthen work. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

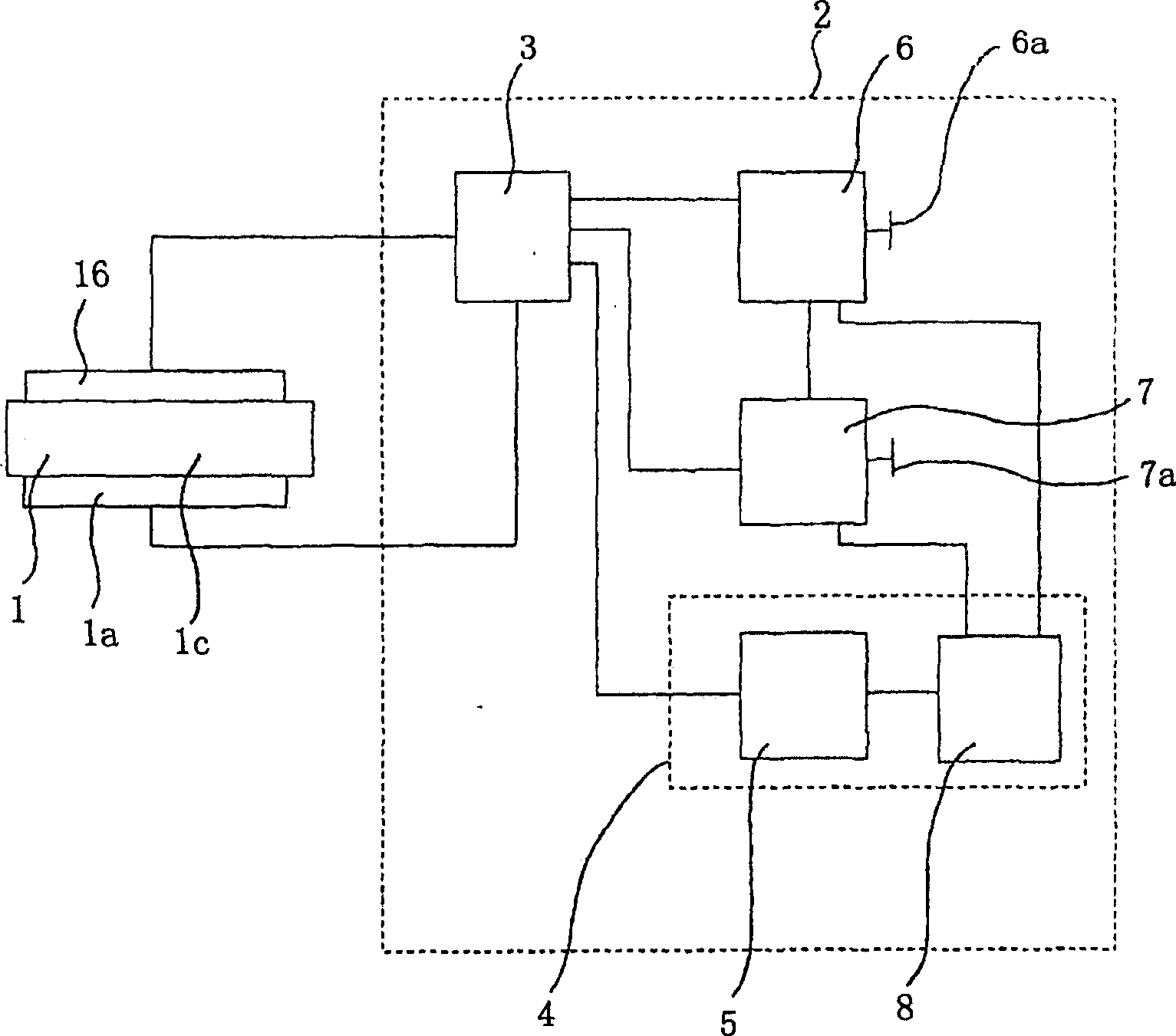

[0041] figure 2 A schematic arrangement of an organic light-emitting element 1 is shown with a corresponding circuit 2 for operating the organic light-emitting element 1 in a pulsed operating mode. The role of the electrodes 1 a , 1 b , which are connected to the control circuit 3 , is to apply electrical control pulses to the organic region 1 c between these two electrodes. Applying an electrical control pulse to the organic light-emitting element 1 via the control circuit 3 excites the emitter material in the organic region 1c to emit light. A plurality of different emitter materials, each emitting light of a different color, are arranged in the organic region 1c. In this way, the light emitted from the organic region 1c, in particular it can be white light, is of mixed colours.

[0042] By means of the circuit 2, the organic light-emitting element 1 is supplied with electrical control pulses, the height and length of which pulses are adjustable independently of each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com