Process for preparing boron hydride by electrolytic method

A technology of borohydride and electrolysis, applied in electrolysis process, electrolysis components, etc., to achieve the effect of increasing current density, increasing electrochemical reaction rate, and increasing electrode surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

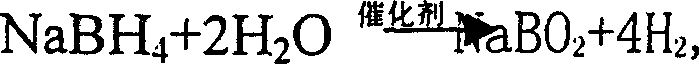

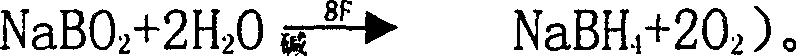

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Choose titanium-based manganese dioxide as the anode, nickel as the cathode, 2.0mol.l -1 NaOH and 2.0mol.l -1 The metaborate is the cathodic solution, 2.0mol.l -1 h 2 SO 4 It is the anode solution, the temperature is 40°C, and the current density is 80mA / cm 2 , electrolysis for 2 hours, the current efficiency was 32%.

Embodiment 2

[0012] Choose titanium-based manganese dioxide as the anode, iron as the cathode, 2.0mol.l -1 NaOH and 2.0mol.l -1 The metaborate is the cathodic solution, 2.0mol.l -1 HCL is the anode solution, the temperature is 48°C, and the current density is 100mA / cm 2 , electrolysis for 2 hours, the current efficiency is 30%.

Embodiment 3

[0014] Choose lead dioxide as the anode, graphite as the cathode, 2.0mol.l -1 NaOH and 2.0mol.l -1 The metaborate is the cathodic solution, 2.0mol.l -1 HCl is the anode solution, the temperature is 45°C, and the current density is 100mA / cm 2 , electrolysis for 2 hours, the current efficiency is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com