Bushing

A sleeve and insulating core technology, applied in the field of indoor or outdoor sleeves and the construction of the sleeves, can solve the problems of no cost efficiency and the like, and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Description of preferred embodiments

[0027] The following description refers to both methods and apparatus.

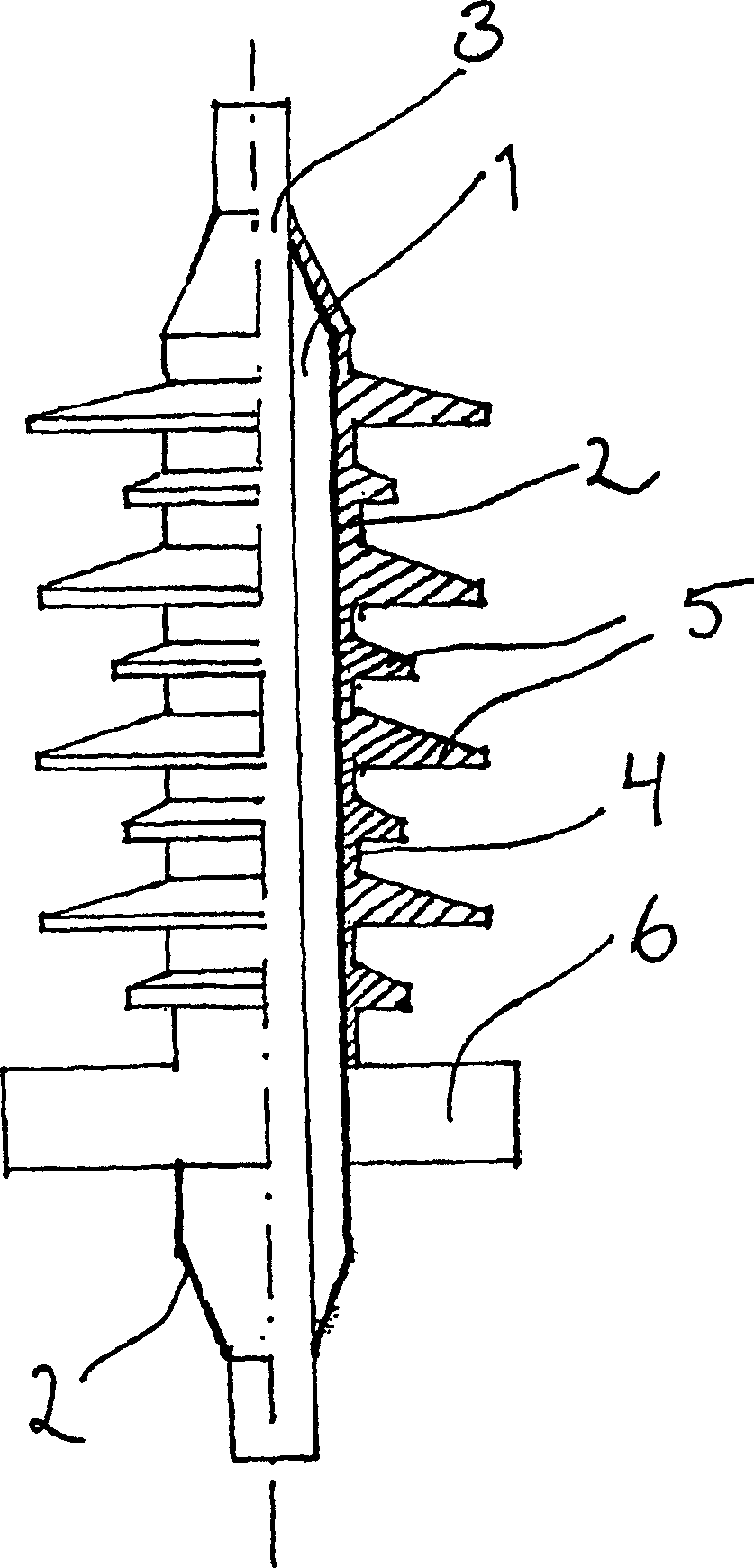

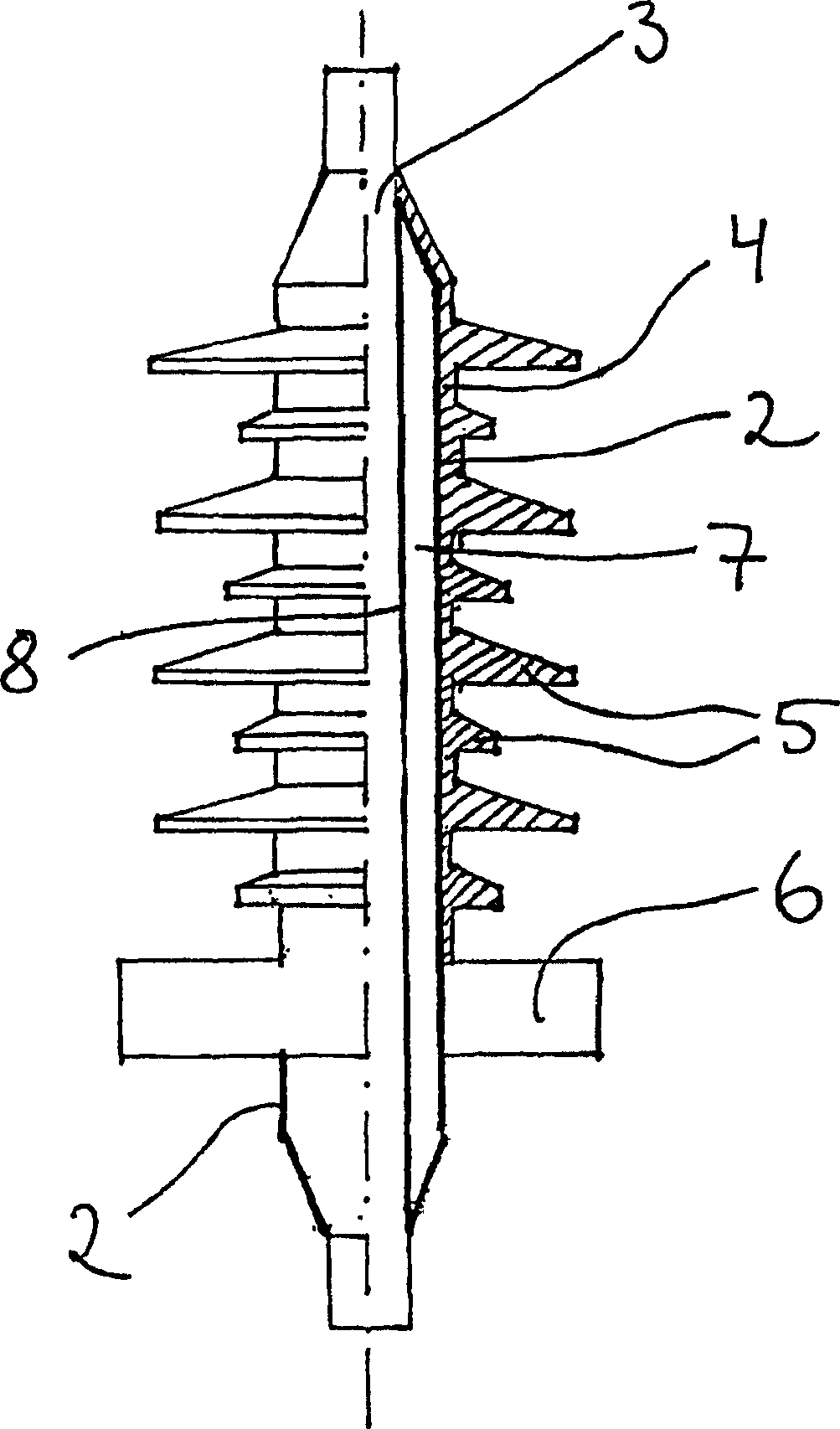

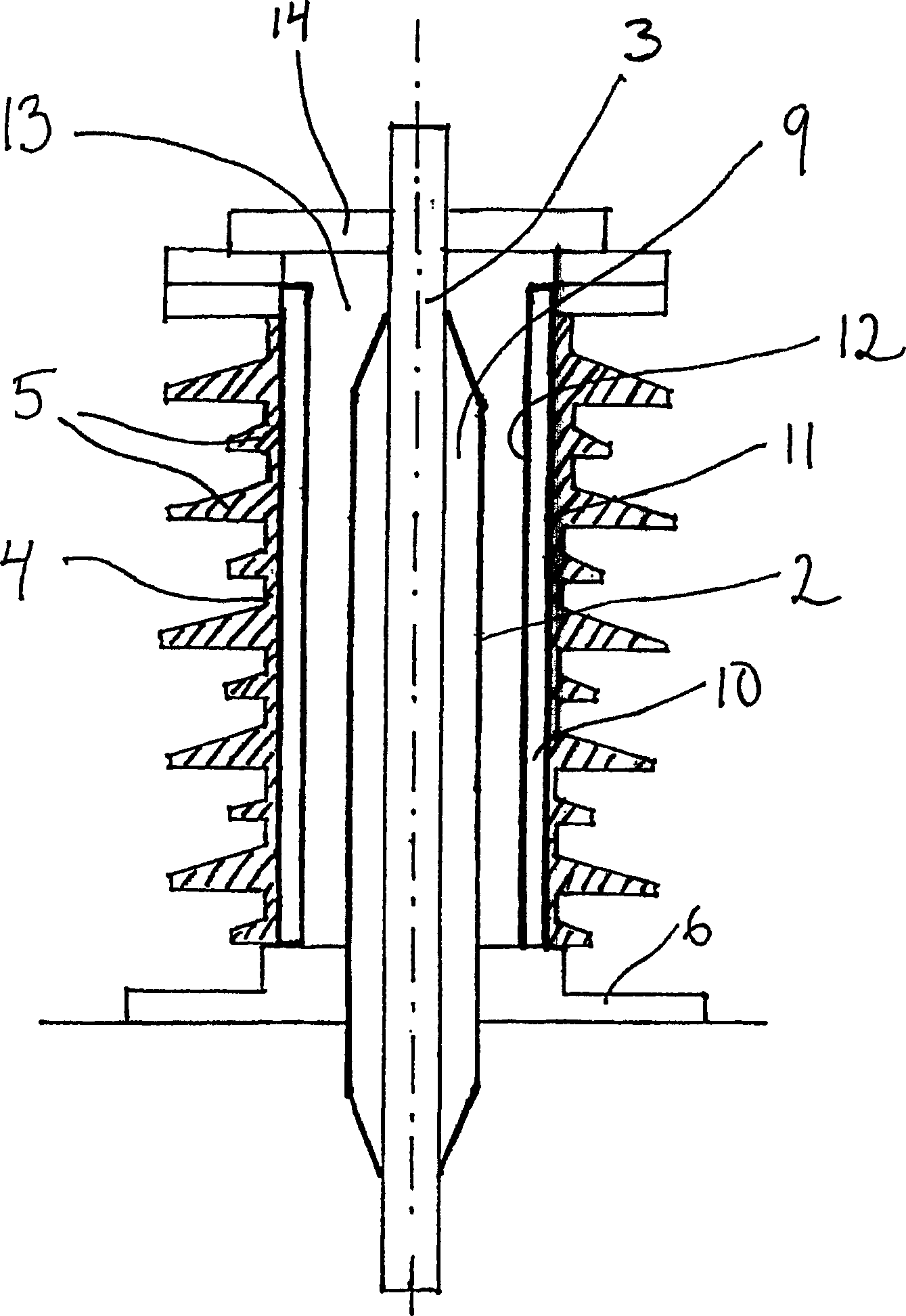

[0028] figure 1 A bushing according to a preferred embodiment of the invention is shown. The bushing comprises, an insulating core 1 comprising a diffusion barrier 2 . Diffusion barrier 2 consists of a continuous membrane, the figure 1 wherein it covers substantially the entire surface of the insulating core. The central tube 3 is arranged in the center of the casing. The central tube 3 may or may not be in the current carrying path. The insulating core is made, for example, of a composite material comprising epoxy, such as epoxy resin impregnated paper (RIP). Insulating cores can be produced by wrapping paper and equalizing plates on a central tube, then impregnated with resin in a mould. These equalization plates (not shown) are made of metal foil, preferably aluminum foil, or conductive ink, and are used to control the electric field inside and outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com